Simo motors successfully repaired the core high-voltage motor of a large mining company

Date: 2023-08-21 Categories: Cases Views: 1232

Excerpt:

This article analyzes the whole process of repairing a critical 10kV, 1800kW high-voltage motor for a large mining company. In the face of the motor's stubborn faults of excessive vibration and repeated bearing burnout, the Simo team not only eradicated the problem through precise diagnosis and systematic maintenance programs, but also established a predictive maintenance system for the client, avoiding major production stoppage losses. This case demonstrates Simo's comprehensive technical strength and service value in the field of large motor maintenance.

Article Catalog[Hidden]

I. Customer Background and Fault Challenges

Customer Information:

- Customer Name: A major domestic metal mining group (name withheld at client's request)

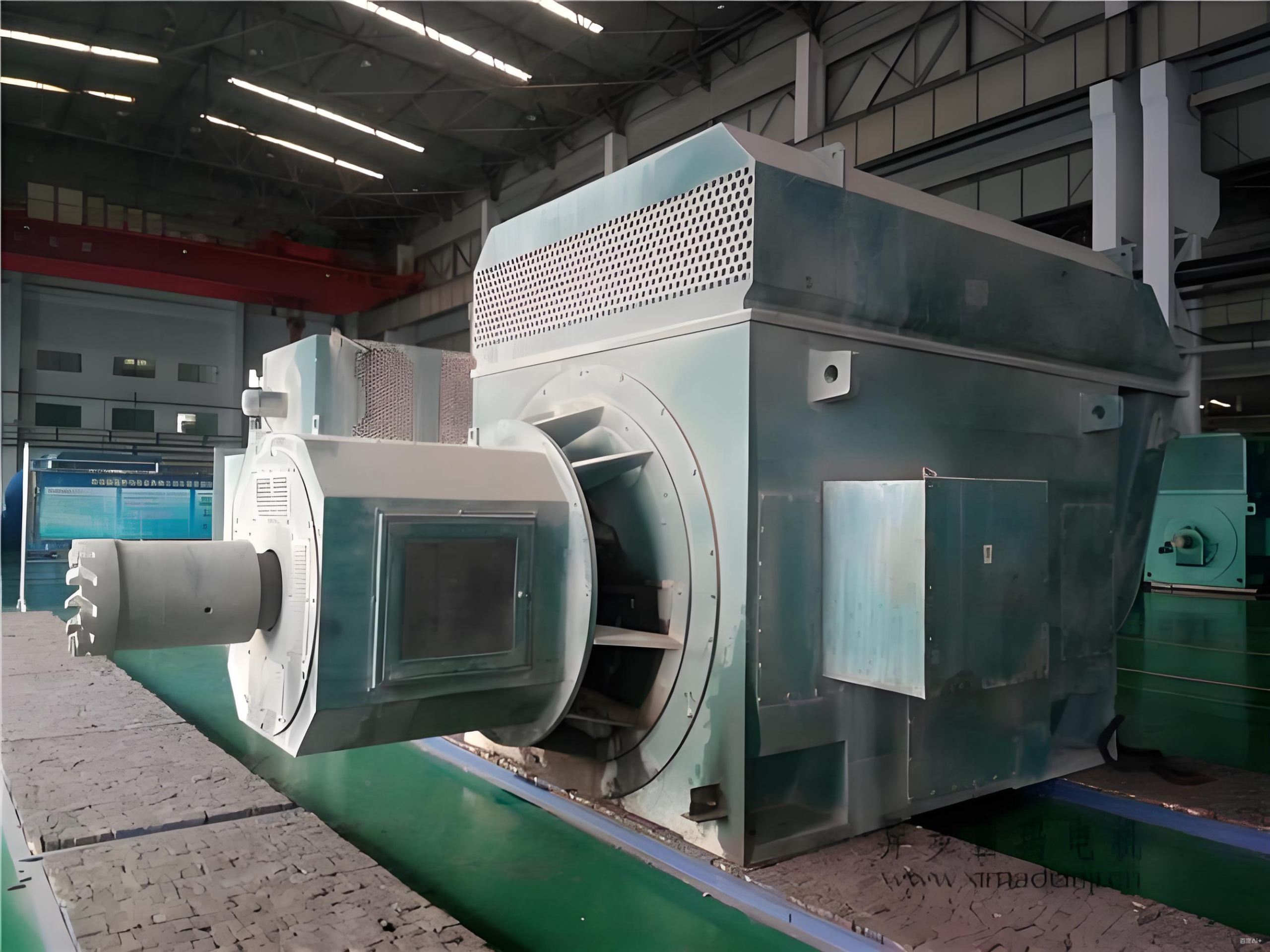

- Faulty Equipment: 10kV High-Voltage Asynchronous Motor for Ball Mill Drive

- Key Parameters: rating1800 kWRated Voltage10kVRotational speed: 992 rpm

- Core issues:

- Violent vibration: The vibration value at the non-drive end of the motor has persistently exceeded the limit, reaching as high as 8.5 mm/s—far surpassing the 4.5 mm/s threshold permitted by the ISO 10816 standard.

- Repeated bearing failures: Bearings at the same location failed twice in quick succession, posing a serious threat to continuous production and placing immense pressure on the customer to halt operations.

II. In-Depth Diagnosis: Identifying the Root Cause of the Malfunction

Simo motorsA team of senior engineers arrived on-site with specialized equipment and conducted an in-depth diagnostic analysis that far exceeded standard procedures.

1. Multi-dimensional Data Collection and Analysis

- Vibration Spectrum Analysis: Using a vibration analyzer to collect data, the spectrum shows intenseCharacteristic Frequency of Bearing Outer Ring Failureand the frequency-shifted sidebands, while simultaneously exhibiting significant unbalanced components.

- Laser Alignment Inspection: A discrepancy was found between the motor and the load.0.25mm angular misalignment errorThis is the primary cause of abnormal axial force generation.

- Infrared Thermal Imaging Scan: An abnormal temperature gradient was detected in the bearing housing, indicating internal friction and inadequate lubrication.

2. Root Cause Identification

By synthesizing all the data, the team identified the root cause of the recurring issues.Three Root Causes:

- Root Cause 1: Bearing Housing WearLong-term vibration causes fretting wear in the bearing housing, resulting in excessive internal bore dimensions that compromise the essential interference fit between the bearing and housing bore.

- Root Cause 2: Poor Alignment with ChinaInsufficient installation alignment accuracy subjected the bearings to additional axial and radial loads, accelerating their fatigue failure.

- Root Cause Three: Improper Lubrication ManagementThere are issues with mixing grease types and inaccurate filling quantities.

III. Systematic Maintenance Solutions and Implementation

In response to the aforementioned complex failure, Xima Electric Motors formulated and implemented a comprehensive repair plan that addresses both the symptoms and root causes.

1. Core Component Repair and Reinforcement

- Bearing Housing Repair: adoptionLaser Cladding TechnologyPerform precision restoration on worn bearing housings to restore their standard dimensions and tolerances, ensuring perfect fit with new bearings.

- Bearing Upgrade: SelectImported SKF/C&U Ultra-Quiet Bearingsand strictly adhere to the hot-fitting process during installation to ensure optimal clearance and fit tolerances.

2. Precision Calibration and Balancing

- Laser Alignment Calibration: Using a laser alignment tool, calibrate the alignment accuracy between the motor and the load toWithin 0.05 mmEliminate abnormal stresses at their source.

- High-Speed Dynamic Balancing of Rotors: Perform precision balancing on the rotor using a dynamic balancing machine to reduce residual imbalance toG1.0 GradeSuppress vibration at its source.

3. Standardized Assembly and Debugging

- Standardized Lubrication Management: Thoroughly clean the lubrication lines, use the specified high-performance grease, and precisely control the filling quantity with dedicated tools.

- Comprehensive Inspection: After maintenance completion, insulation resistance testing, DC withstand voltage testing, and no-load trial operation were strictly performed, with all parameters exceeding standards.

IV. Maintenance results and customer value

- The fault is completely eradicated: After repair, the motor vibration value decreased to1.8 mm/sThe equipment is operating smoothly with normal temperatures.Continuous stable operation exceeding one full production cycleNo further malfunctions have occurred.

- Production Assurance and Efficiency Enhancement: Avoided substantial production losses for the client due to prolonged downtime of core equipment, estimated at millions of yuan.

- Management Upgrade: Xima Electric assisted the client in establishingEquipment Health Records and Predictive Maintenance SystemThis marks a modern management transformation from “reactive repairs” to “proactive prevention.”

- Securing Strategic Partnerships: This exceptional service experience has led the mining group to designate Xima Motors as itsHigh voltage motorsStrategic Maintenance Service ProviderA long-term maintenance agreement has been signed.

V. Case summary and inspiration

1. Core message

- Systemic thinking is crucial: Complex failures in large electric motors are often the result of intertwined root causes. A systematic diagnostic approach must be adopted to avoid treating symptoms rather than the underlying problem, thereby ensuring a thorough resolution.

- Precision Data-Driven Decision Making: Data obtained through vibration analysis and laser alignment of precision instruments is the only reliable basis for achieving accurate diagnosis and maintenance.

- Workmanship standards determine repair quality: From bearing installation to alignment calibration, the adherence to technical specifications in every step collectively determines the final outcome and service life of the maintenance.

2. Management Recommendations for Industrial Clients

- Investing in Predictive Maintenance Technology: By introducing tools such as vibration monitoring and infrared thermal imaging, potential equipment failures can be detected early.

- Establish standardized maintenance procedures: Develop and strictly enforce operational standards for the installation, alignment, and lubrication of critical equipment.

- Select partners with comprehensive capabilities: Maintenance service providers must possess advanced diagnostic capabilities, high-end repair techniques, and systematic management expertise to deliver long-term reliability.

(Call to Action CTA)

Is your large motor also facingThe frustration of recurring failures, performance degradation, or unexpected downtimeAre you looking for a solution that can provideFundamental solutionA reliable partner?

Contact the Simo Motors expert team todayGet free technical consultation and a preliminary equipment health assessment! We promise to deliver large motor repair, maintenance, and full lifecycle management services with the same level of professionalism and systematic approach as this case study.

Xi'an Simo Motor —— Your Trusted Partner for Large Industrial Motor System Solutions

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206