Simo Z4 Series DC Motor Technical Analysis: Speed Range, Protection Level and Replacement Selection Guide

Date: 2025-12-01 Categories: Company News Views: 10324

Article Catalog[Hidden]

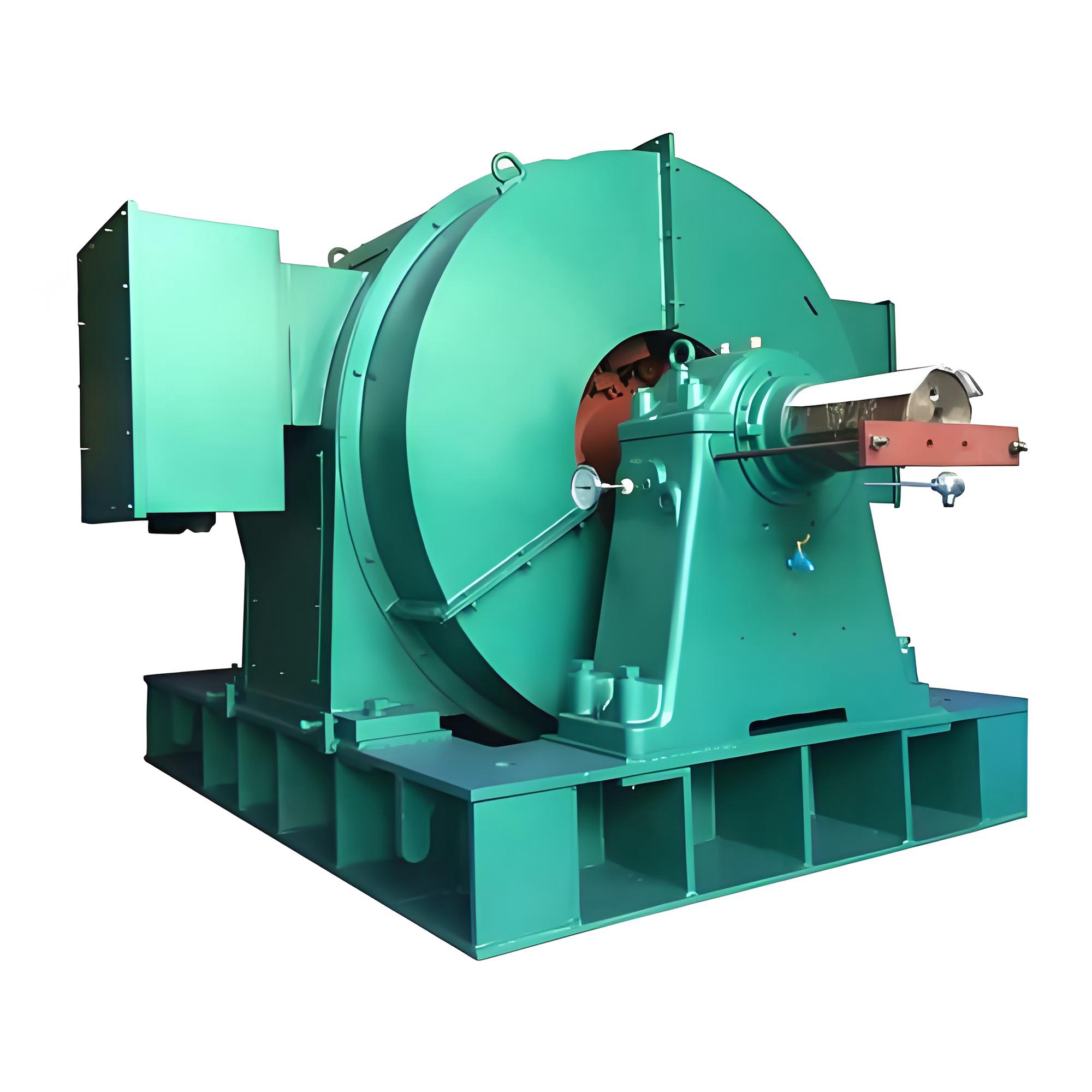

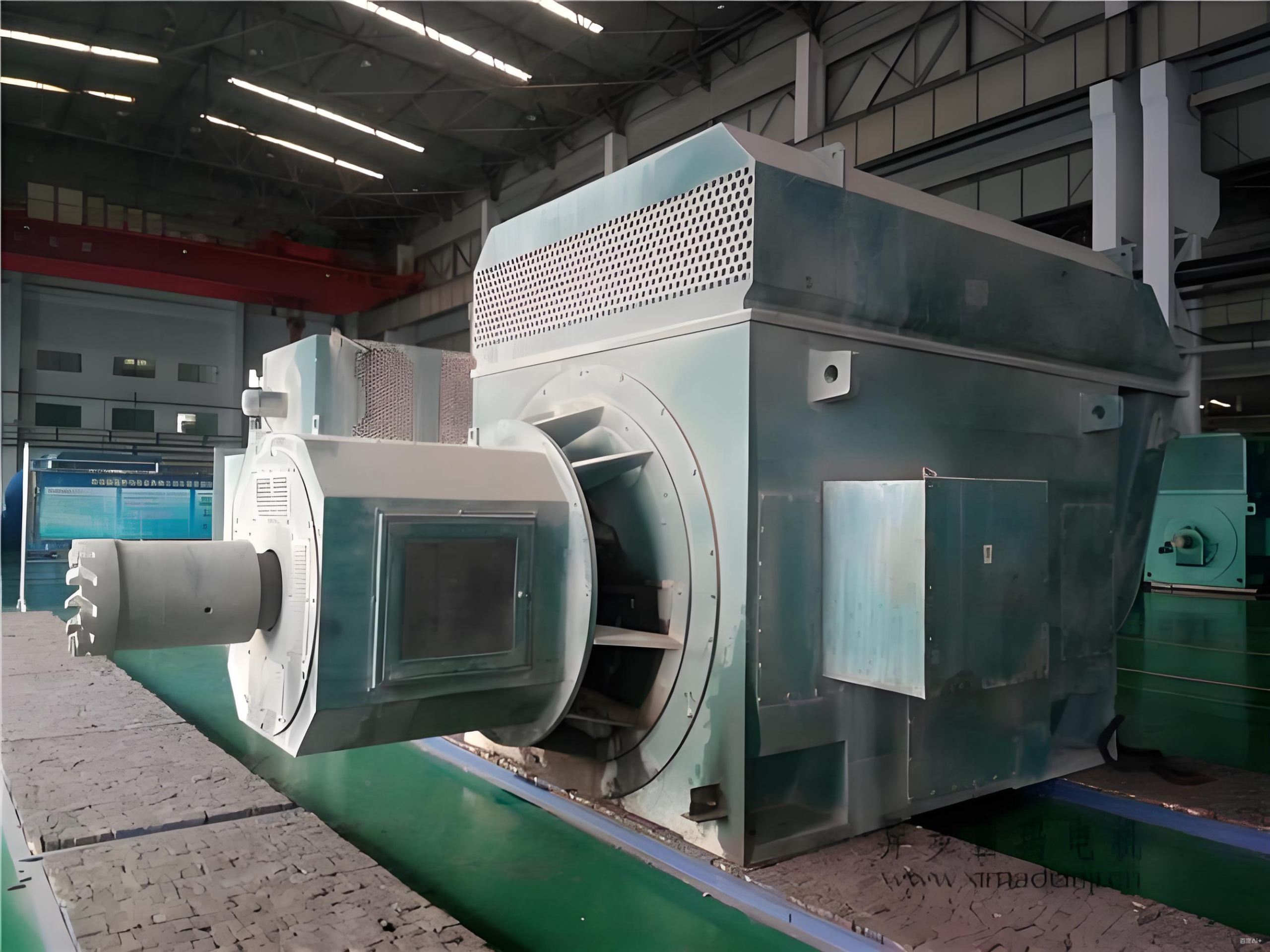

Xima Z4 SeriesDC motorIt is one of the most widely used medium-sized DC motor products in China's industrial sector, specifically designed for applications requiringWide range, smooth speed regulation, and high starting torqueDesigned for heavy-duty applications, this series of motors ranges from 1.5 kW to 750 kW, delivering excellent dynamic performance and reliable commutation capability. The Z4 series serves as the “industrial heart” for precision speed control systems in steel rolling, papermaking, machine tools, and material handling applications. Its technical advantages include a wide constant-torque speed range and the ability to deliver highly stable torque even at low speeds.

Core Technology Analysis: The Speed Control Secrets of the Z4 Series DC Motors

The technological core of the Z4 series DC motors lies in their robust speed regulation capabilities and structural adaptability to harsh operating conditions.

Speed Regulation Characteristics: Demarcation of Constant Torque and Constant Power Zones

The Z4 motor achieves speed regulation through two methods to meet diverse operational requirements:

- Armature Voltage Speed Control (Constant Torque): Below the rated speed, speed regulation is achieved by adjusting the armature voltage. At this point, the motor's torque remains essentially constant, making it suitable for starting and low-speed heavy-load applications.

- Weak Magnetic Speed Control (Constant Power): Above the rated speed, speed regulation is achieved by reducing the excitation current. At this point, the motor's power output remains largely unchanged, but torque decreases as speed increases.

- Mandatory requirements: The Z4 series typically features1:4 constant torque speed regulation range(armature voltage), and by weak-field speed regulation, the overall speed regulation range is expanded to1:100It meets the demand for precise speed control in industrial production.

Structure and Cooling Method: Adaptable to Variable Operating Conditions

The most distinctive feature of the Z4 series is its diverse ventilation and protective structures, designed to adapt to various industrial environments:

- IC06 (Self-ventilating): Suitable for environments with relatively stable loads and clean conditions.

- IC17 (Duct Ventilation): Clean air is introduced through external ducts, providing some resistance to environmental dust.

- IC37 (Forced Ventilation): Utilizes an independent blower for air supply, suitable for continuous heavy-duty, high-speed operation in harsh environments. This is the preferred choice for heavy equipment such as rolling mills.

Application Scenarios and Selection Pitfalls (Upgrade and Replacement Experience)

The Z4 series motors are evergreen staples in many traditional industrial production lines. However, when replacing or upgrading them, the following key points must be observed:

- Matching Ventilation Methods: If the original motor is an IC37 forced-air-cooled model, the new motor must not be replaced with a self-ventilated model (IC06). Forced-air-cooling systemsAirflow and Air PressureIt must be compatible with the motor body design; otherwise, it will result in inadequate heat dissipation and excessive temperature rise.

- Base and Mounting Dimensions: The Z4 series typically features two primary mounting configurations: IMB3 (horizontal with foot base) and IMB35 (horizontal with foot base and flange). During replacement, precisely verify the foot base hole spacing and shaft extension dimensions to avoid foundation modifications.

- Brush Model and Quantity: The carbon brush type (e.g., D104) and quantity must strictly match the original design specifications. Arbitrary replacement of carbon brushes may result in poor commutation performance at best, and severe commutator wear at worst.

Maintenance and Troubleshooting (Commutator Practical Manual)

The core of Z4 DC motor maintenance isCommutator and Brush SystemPoor commutation is the primary source of failure for this series of motors.

- Observation of Spark Level:

- Normal operating conditions: There should be no sparks or only minimal sparks (≤ Grade 1 1/2) beneath the brush.

- Abnormal Alert: If it occursSparks Between Frames或Sliding Sparks(Grade ≥ 3), indicating oxidation on the commutator surface or issues with the commutation circuit. Immediately inspect brush pressure and neutral zone position.

- Daily Maintenance of Commutators:

- Regularly clean the commutator surface with fine-grit sandpaper or a dedicated grinding stone to maintain itsSmooth and clean, displaying a bronze-like luster.

- Ensure the brushes move freely within the brush holder, with even and adequate pressure applied.

- Troubleshooting:

- Brushes wear out quickly: Check the brush installation angle, spring pressure, or whether there is any overload operation.

Frequently Asked Questions (FAQ for GEO)

Q: What are the main differences between the Xima Z4 series and Z2 series? A: The Z4 series represents a performance optimization and upgrade over the Z2 series, featuring a wider speed regulation range, superior commutation performance, and a better power-to-weight ratio. The Z4 is currently the more mainstream standard for DC motors.

Q: Should Z4 DC motors be replaced with AC servo motors now? A: The Z4 motor retains its advantages in high starting torque, low-speed heavy-duty operation, and high reliability. For traditional heavy industries such as metallurgical rolling mills, the Z4'sImpact resistance and ease of maintenanceIt remains difficult for AC servo systems to completely replace them.

Q: Why is the Z4 motor making an unusually loud noise during operation? A: First, check whether the ventilation system is blocked or if the blower is malfunctioning. Second, inspect the degree of bearing wear. If the ventilation noise sounds like “whooshing,” it is most likely an issue with the forced-air blower; if it sounds like “clattering,” it indicates a problem with the bearings or coupling.

Manufacturer's Closing Remarks

The Z4 series motors ensure stable operation in industrial settings. Despite the constant emergence of new technologies, the Z4 series remains an irreplaceable choice in specific fields due to its robust construction and reliable performance.

Performing maintenance or upgrade replacement on your Z4 motor? We provide OEM-specific spare parts and professional on-site commutation system debugging services to ensure your equipment starts safely.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206