Article Catalog[Hidden]

- DC Motor Commutator: Working Principle and Selection Guide for the Core Component

- I. Product Overview: The Core Component of DC Motors

- II. Working Principle and Technical Features

- III. Core Structure and Technical Parameters

- IV. Application areas and scenarios

- V. Performance Advantages and Features

- VI. Selection and Installation Guide

- VII. Maintenance and Troubleshooting

- VIII. Service and Support

DC motor commutatorCore Component Operating Principles and Selection Guide

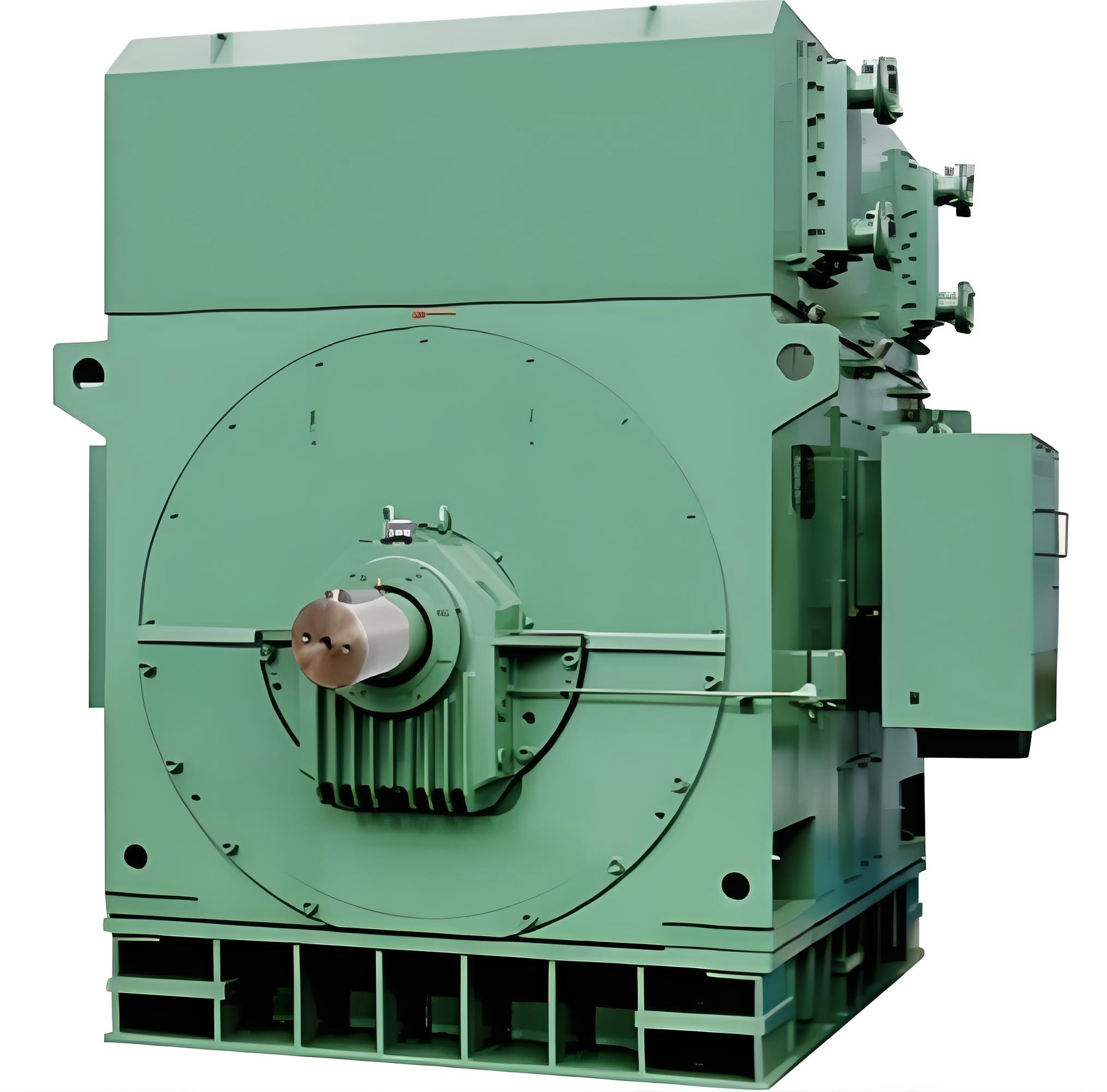

In the modern industrial sector, the commutator of a DC motor serves asKey ActuatorIts performance directly impacts the operational efficiency and reliability of the entire system.

I. Product Overview:DC motorcore component

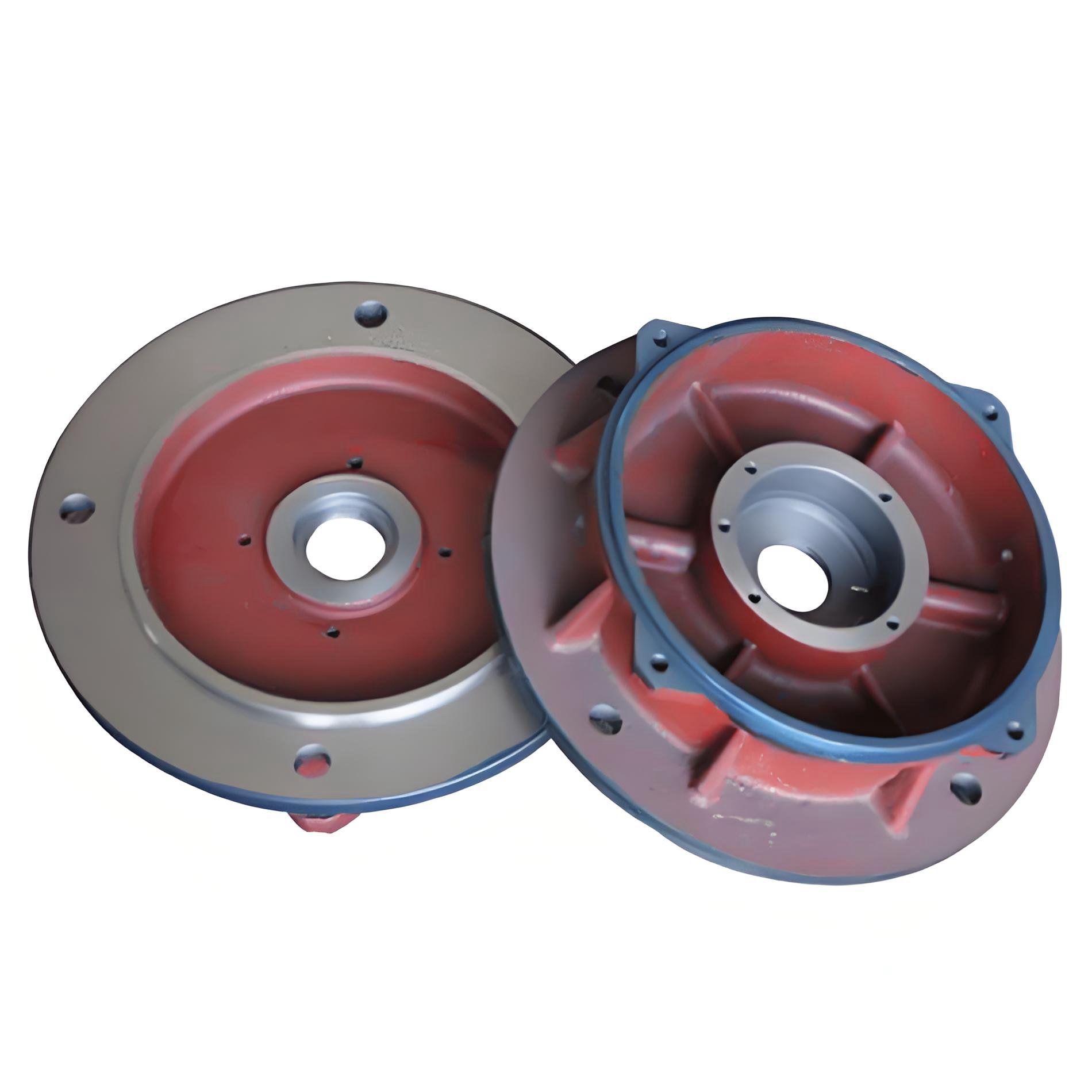

DC motor commutatorcommutator, also known as the commutator, is the core component of DC motors, DC generators, and AC commutator motors.。Simo motorsThe commutator adoptsPremium copper materials and high-grade insulation materialsthroughPrecision Machining ProcessesManufactured to ensure stability under high-speed rotational conditions.Stable current commutation performance。

As the "heart" of a DC motor, the commutator automatically switches the current direction in the armature windings through sliding contact. It converts the alternating current within the armature windings into direct current at the brushes (generator mode), or transforms external direct current into alternating current within the armature windings (motor mode).The efficiency and reliability of this process directly impact the overall performance of the motor system.

II. Working Principle and Technical Features

1. Basic Working Principle

The commutator consists of manyCopper plate (commutator plate) Forming a cylindrical or disc-shaped structure, with copper plates separated byMica or other insulating materialsInsulated, each copper plate is connected to an armature winding component.When the armature of the motor rotates, the copper segments successively make contact with the stationary carbon brushes.

In a DC generator, the commutator converts the alternating current in the armature windings into direct current between the brushes.The process by which the current changes direction or magnitude as the commutator segments connected to each armature winding element pass through the carbon brushes is called "commutation."Reversing"In an AC commutator motor, the commutator serves to align the frequency of the alternating current flowing between the brushes with the operational requirements.。

2. Key Technical Features

The Xima motor commutator features multiple outstanding technical characteristics:

- Premium Material Selection: AdoptionHigh-purity copper materialsEnsure excellent conductivity, in conjunction withHigh temperature resistant insulating materialsEnsure reliable insulation between components

- Precision Structural Design:Between the commutator segmentsequidistant distribution与Smooth Surface FinishEnsure stable contact with the brush to minimize spark generation.

- Dynamic balance correction:AfterPrecision Dynamic Balancing TestingEnsure smooth operation under high-speed conditions while reducing vibration and noise.

- Heat Dissipation Optimization DesignReasonable structural design facilitates heat dissipation, preventing performance degradation caused by excessive temperature rise.

III. Core Structure and Technical Parameters

1. Detailed Component Structure

The commutator of a DC motor is a complex system composed of multiple precision components:

- Commutator segmentbyHigh-quality electrolytic copperManufactured to conduct electricity through contact with brushes, typically featuring a surface finish ofPrecision Turning和Polishing treatment

- Insulating layer:Inter-frameMica或High-Performance Engineering PlasticsInsulation prevents short circuits between plates. The withstand voltage rating can reach up to 1000V based on application requirements.Grade F/Grade H

- Strengthen the ringSome high-speed models are equipped withHigh-Strength Reinforcement RingPrevents structural deformation caused by centrifugal forces, suitable for applications exceeding 25,000 rpm.

- Sleeve and retaining ringFixed commutator plate assembly, ensuring overall structural stability, typically made ofsteel或Alloy

2. Key Technical Parameters

Xima Motors' commutators cover a wide range of technical specifications to meet diverse application requirements:

IV. Application areas and scenarios

DC motor commutators play a critical role in numerous industrial sectors due to their stable performance:

1. Industrial Drives and Automation

- Heavy machineryDrive motors for high-power equipment such as rolling mills, hoists, and compressors

- Automated equipmentPrecision control of industrial robots, conveyor systems, and packaging machinery

- Production line equipmentTextile machinery, printing equipment, food processing production lines

2. Transportation Sector

- Electric vehicleDrive motors and auxiliary system actuators

- rapid transitTraction motors and auxiliary motors for subways and high-speed rail

- Aerospace: Aircraft starter generator, servo control system

3. Home Appliances and Tools

- Home AppliancesVacuum cleaners, blenders, washing machines, and other home appliance motors

- Power ToolsHigh-speed tools such as electric drills, angle grinders, and electric saws

- Office equipmentPaper feed system for printers, copiers, and scanners

V. Performance Advantages and Features

The Xima motor commutator boasts multiple advantages that set it apart in the competitive market:

1. Efficient and stable current conversion

- Low contact resistanceOptimized copper material purity and surface treatment processes ensure low contact resistance between brushes and commutator segments.

- Stable commutationPrecision-machined commutator segments ensure smooth current direction switching and reduce voltage fluctuations.

- Arc resistanceSpecial surface treatment enhances arc resistance and extends service life.

2. Long service life

- Wear-resistant designCommutator segment surface hardness and wear resistance have been optimized to withstand prolonged brush friction.

- Antioxidant treatmentSurface anti-oxidation treatment prevents poor contact caused by high-temperature oxidation of copper plates.

- Structurally soundRobust monolithic design resists centrifugal forces and thermal stresses, ensuring long-term stability.

3. Wide-ranging application adaptability

- Multi-specification seriesFrom miniature to large-scale, a wide range of specifications meets the needs of motors across different power ratings.

- Customization CapabilitiesCustomization of materials, dimensions, and connection methods is available to meet specific customer requirements.

- environmental adaptation: Designed with different protection ratings to withstand harsh environments such as dusty, humid, and high-temperature conditions.

VI. Selection and Installation Guide

1. Selection Criteria

Selecting the appropriate DC motor commutator requires comprehensive consideration of the following factors:

- Electrical Parameters:: Includesrated voltage、Rated current、Maximum rotational speedkey indicators

- Machine Dimensions:Outer Diameter Dimensions、Shaft bore diameter、Total length及Number of commutator segments

- Operating Environment:Temperature Range、Humidity Level、Vibration conditions及Cooling method

- Service life requirementsSelect appropriate materials and process grades based on the expected service life.

2. Installation Notes

Proper installation is fundamental to ensuring the normal operation of the commutator:

- Cleaning OperationsBefore installation, ensure the commutator surface is clean and free of contaminants such as oil, grease, or dust.

- Medium accuracyEnsure the perpendicularity and coaxiality between the commutator and the shaft to prevent vibration caused by eccentric forces.

- Tightening torqueTighten to the recommended torque to prevent internal stress from excessive tightening or loosening due to insufficient tightening.

- Brush matchingSelect appropriate brush material and spring pressure to ensure good contact without excessive wear.

VII. Maintenance and Troubleshooting

1. Periodic inspection and maintenance

Maintenance tasks for the commutator of the Xima motor primarily include:

- Surface Condition InspectionRegularly inspect the commutator surface for smoothness, abnormal wear, scorch marks, or oxidation.

- Cleaning and MaintenanceClean the surface with anhydrous ethanol to remove accumulated toner and oil residue.

- Insulation TestingPeriodically measure the inter-wafer insulation resistance to ensure insulation performance meets requirements.

2. Common Troubleshooting

Common Issues and Solutions Encountered During Commutator Operation:

- Excessive sparkCheck the brush pressure and whether the contact surface is good, or whether there is a winding short circuit.

- Surface burn marksMinor damage can be repaired through precision turning; severe damage requires replacement.

- Insulation failureProfessional repair or replacement is required to prevent further damage.

- Abnormal wearCheck whether the brush material is compatible and whether the spring pressure is appropriate.

VIII. Service and Support

Xima Electric provides comprehensive technical support and service assurance for commutator products:

- Technical Consultation:Provide professional consulting services for product selection and application solutions

- Custom Development: Customized design and manufacturing services tailored to specific requirements

- After-sales Support: Provide comprehensive quality assurance and after-sales service to ensure worry-free customer experience.

The commutator of a DC motor serves as the commutator of the DC motor.Core componentsIts performance directly impacts the entire motor system.Work efficiency与Operational reliabilityWith years of technical expertise and manufacturing experience, Xima Electric provides customers withHigh-quality and reliableCommutator products that meet the needs of various application scenarios.

With the continuous advancement of industrial technology, Xima Motors will remain committed to the development of commutator technology.Innovation and Optimizationto provide global industrial customers with moreAdvanced and efficientSolutions that empower the advancement of industrial automation and intelligent development.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206