Article Catalog[Hidden]

- YX Series High-Efficiency High-Voltage Three-Phase Asynchronous Motors: The Perfect Combination of Outstanding Energy Efficiency and Reliable Power

YX series high efficiency high voltage three-phase asynchronous motorExceptional energy efficiency and dependable power perfectly combined

In the industrial power sector, the YX series of high-efficiency, high-voltage three-phase asynchronous motors is gaining prominence with itsExcellent energy efficiency performance和Reliable operating characteristicsIt has become the preferred solution for energy-saving retrofits and power upgrades in various industries.

YX series high efficiency high voltage three-phase asynchronous motor是Simo motorsYears of experience in designing and manufacturingEnergy efficient power equipmentAdoptionAdvanced electromagnetic optimization design and precision manufacturing processespossessHigh efficiency, significant energy saving, reliable operation, long service lifeand other outstanding features. This series of motors strictly followT/STIC C110040-2021Technical Specifications for YX Series High-Efficiency High-Voltage Three-Phase Asynchronous Motors (Frame Sizes 355 to 630)providing reliable solutions for a wide range of industrial users.High voltage motorsSolution.

I. Product overview and technical characteristics

1. Product profile

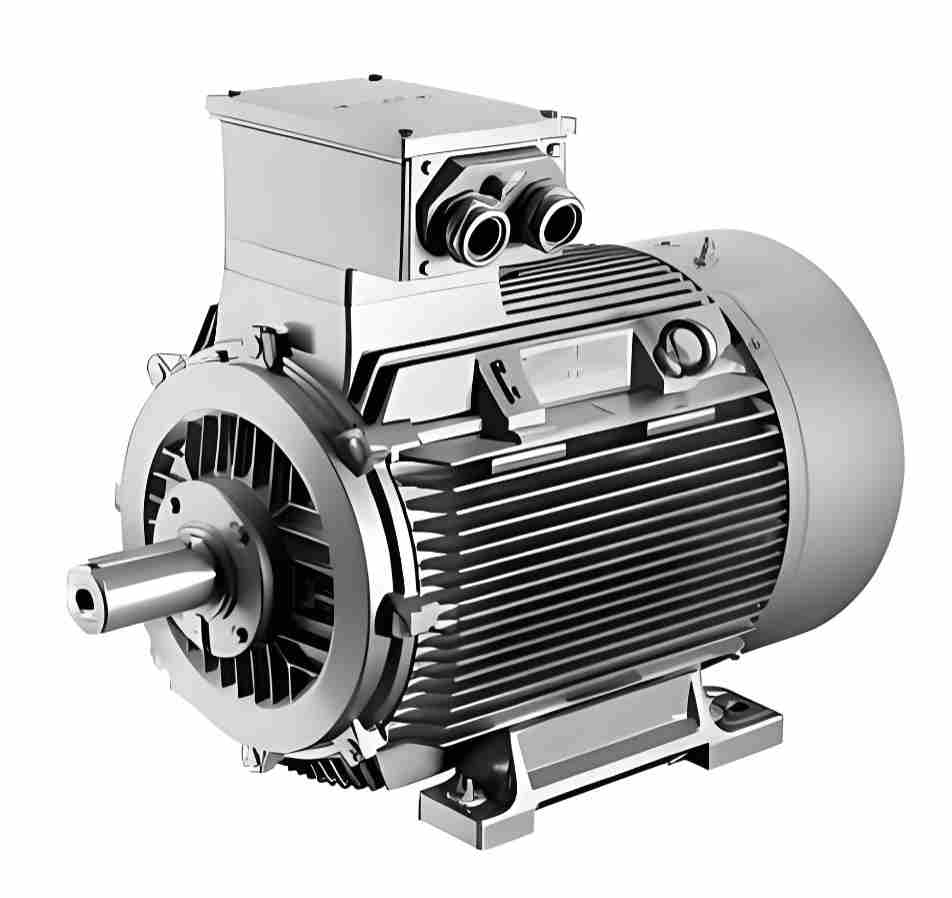

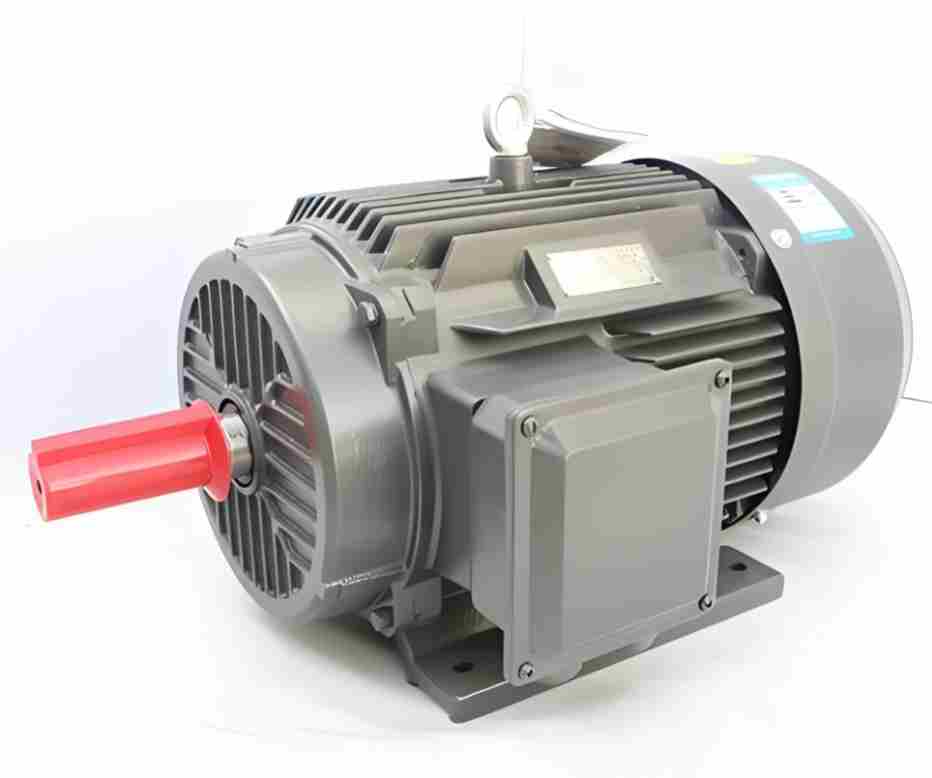

The YX Series High-Efficiency High-Voltage Three-Phase Asynchronous Motors are designed by Xima Motors forModern industry demands both energy consumption and reliabilityThe newly developed high-voltage electric motor. This series of motors covers728 specificationsThe index starts from2P to 12PVoltage levels include6kV and 10kVTwo types, covering a wide power range185 kW to 4000 kWIt can meet the power demands of various industrial scenarios.

As an upgraded version of the Y series motors, the YX series adoptsModular design conceptpossessExcellent electrical parameters, low noise, durability and easy maintenanceand other characteristicsThe series of motors are not only suitable for conventional working conditions, but also can be derived according to users' special requirements. This series of motors are not only applicable to conventional working conditions, but also can be derived according to the user's special needs, providingAir-cooled (YX), Air-water-cooled (YXKK), and Open-type (YXKS) Various cooling methodsAdapt to various complex working environments.

2. Core technical characteristics

The YX Series High-Efficiency High-Voltage Three-Phase Asynchronous Motors integrate multiple innovative technologies, offering significant performance advantages:

- Excellent energy efficiency features: ByOptimized electromagnetic solutions和Low-loss materialsThe application significantly enhances motor efficiency, with the entire product line achievingLevel 1 Energy Efficiency Ratingdelivering significant energy savings for users

- Excellent electrical properties: AdoptionClass F insulation system和VPI Vacuum Pressure Impregnation ProcessSuperior insulation performance, long service lifeThe stator coils are double-layer molded coils, primarily insulated with mica and glass fiber tape, effectively enhancing electrical reliability.

- Robust mechanical constructionThe motor adoptsAll-Steel Plate Welded BaseThrough finite element analysis optimization, it features lightweight construction, excellent rigidity, and an aesthetically pleasing design.The rotor adoptsCage structureBy employing induction heating welding and guide rail expansion forming processes, the motor maintains excellent low-vibration performance during long-term operation.

Technical parameters and performance indicators

The YX series of high-efficiency, high-voltage three-phase asynchronous motors covers a wide range of technical specifications to meet the power requirements of diverse industrial applications:

Main technical parameters

Description of performance characteristics

YX Series Motors inElectromagnetic design, structural strength and thermal performanceAll aspects have been fully optimized:

- High-efficiency rangeThe motor maintains high efficiency across a wide load range, outperforming traditional motors.Significant efficiency gainsEnergy saving is obvious

- High starting torque: Special rotor design providesExcellent startup performanceMeet the starting requirements for equipment such as fans, pumps, and compressors.

- Wide Voltage Adaptability: the ability toGrid voltage fluctuationsStable performance under all conditions, adapting to various grid environments

- Low vibration and low noise: ByPrecision Dynamic Balancing Calibration和Optimized structural designThe motor runs smoothly with significantly reduced noise.

III. Structural design and configuration

1. Motor body structure

The YX Series High-Efficiency High-Voltage Three-Phase Asynchronous Motors adoptModular design conceptEach component is carefully designed and optimized:

- Stand design: AdoptionWelded from high-quality steel plateThrough finite element analysis optimization, it features lightweight construction, excellent rigidity, aesthetically pleasing design, and scientifically positioned lifting points.

- Stator structureThe stator core is made ofLow-loss silicon steel sheetsStacked and pressed. The stator coil adoptsDouble-layer molded coilThe coils are connected by silver-copper brazing.The entire stator winding section adoptsVPI Vacuum Pressure Impregnation Solvent-Free Varnish TreatmentExcellent and reliable insulation properties, high mechanical strength, and strong moisture resistance.

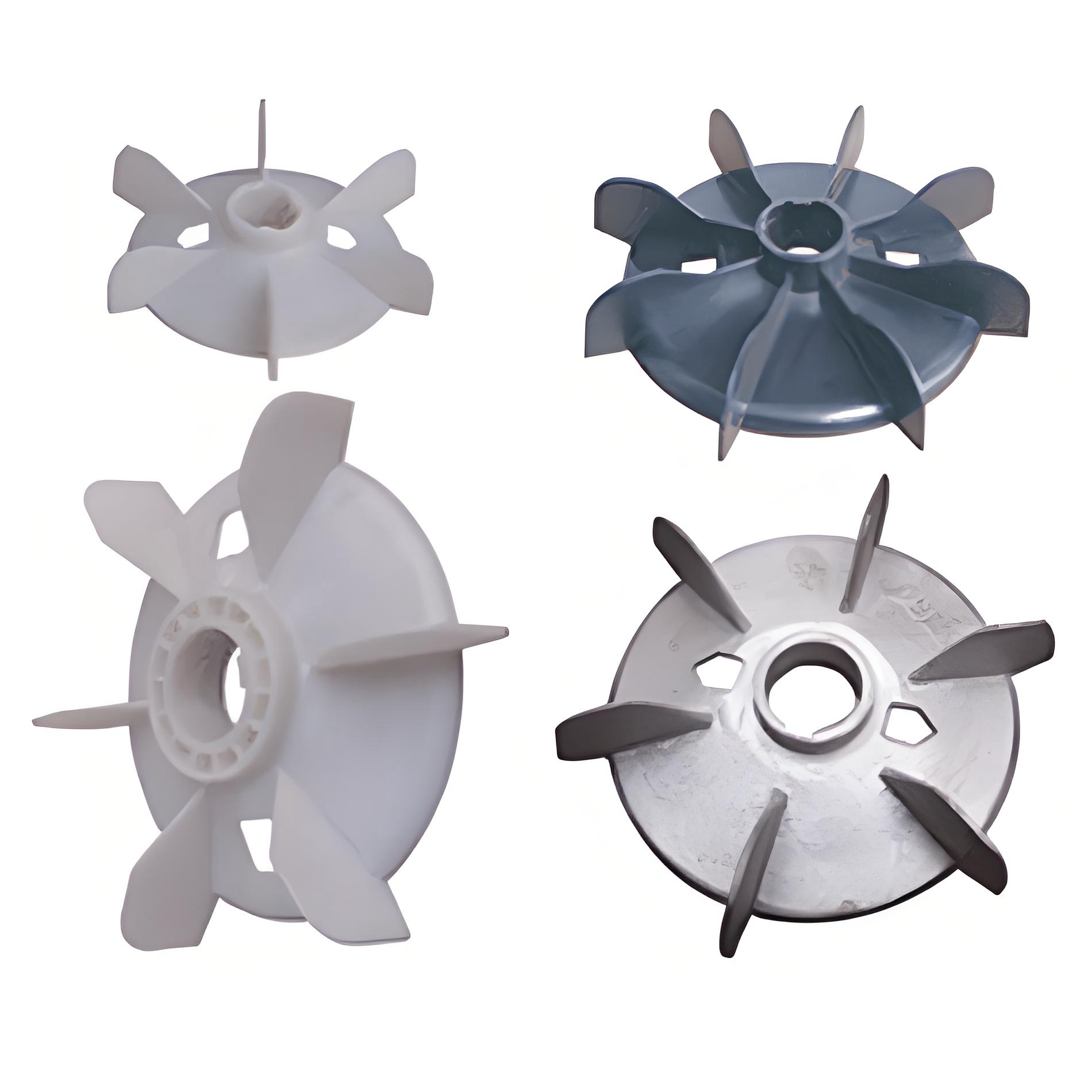

- Rotor construction: The rotor isCage structureAdoptionInduction Heating Welding and Guide Strip Expansion Processand full-speed dynamic balance verificationSelect the rotor shaft material based on application requirements and the environmental conditions at the motor's operating location. For squirrel-cage motors, choose copper or copper alloy conductors depending on the load and customer specifications.

2. Bearings and Lubrication System

YX Series Electric Motors ProvideRolling bearings and sliding bearingsTwo configurations to meet different application needs:

- Rolling Bearing StructureGenerally, the drive side (D-end) is a fixed bearing, while the non-drive side (N-D-end) is a floating bearing.Bearings with a double-ball configuration feature one side of the ball bearings preloaded.The motor can be relubricated without interrupting operation.

- Sliding Bearing DesignThe sliding bearing is designed with a flanged structure and bolted to the end cover.Standard version protection rating: IP55Sliding bearings are typically designed as floating bearings and do not support axial forces.

3. Cooling System Design

The YX series motors offer multiple cooling methods to accommodate various operating environments:

- Air-to-Air Cooler (IC611):Suitable for relatively clean environments

- Air-to-Water Cooler (IC81W)The motor features a fully enclosed design and is equipped with an air-water cooler.A fan mounted on the internal shaft creates a ventilation circuit within the motor.The motor housing features a dust-proof design and can withstand water spray from any direction.

- Open-type (IC01):Suitable for indoor locations with favorable environmental conditions

IV. Application areas and scenarios

The YX series high-efficiency high-voltage three-phase asynchronous motors, renowned for their reliable performance and energy-saving efficiency, are widely utilized across numerous industrial sectors:

1. Heavy industry

- Petrochemical Industry: for drivingCompressors and Pump EquipmentAdapted to the continuous production characteristics of the petrochemical industry

- Electric Power Industry: Applied toPower Plant Auxiliary Equipment、Water pump systemproviding stable power support

- Mining and Metallurgical Industry: Specifically designed forCrusher, coal mill, hoist, rolling millHeavy equipmentWithstands harsh operating conditions

2. General industrial areas

- Fan equipment: Applicable toBlowers, ventilatorsand other equipment, providing efficient power solutions

- Water pump system: Used to drive all types ofIndustrial water pumps, circulating water pumpsMeet the needs of the water supply and drainage system

- transmission mechanism: Applied toBelt presses, conveyorsMaterial handling equipment

3. Special Environment Applications

The YX series motors can also provide customized solutions tailored to specific environmental requirements:

- High-humidity environmentThrough special protective treatment and insulation design, it is suitable for humid environments.

- Dust-laden environmentsFeatures a fully enclosed cooling structure to prevent dust from entering the motor interior.

- high temperature environmentOptimize the cooling system to ensure stable operation in high-temperature environments.

V. Product Advantages and Values

1. Energy efficiency benefits

The YX series high-efficiency high-voltage three-phase asynchronous motors offer significant economic benefits:

- Reduced operating costs: High-efficiency design can beSignificant reduction in energy consumptionReduced payback period

- Optimization of power factorThrough rational design, the motor possessesExcellent power factorReduce investment in reactive power compensation equipment

- Low life cycle costs: Although the initial investment is slightly higher, theEnergy saving benefits during operationDramatic reductions in total life cycle costs

2. Operational reliability

The YX series motors offer distinct advantages in reliability:

- Rugged structural design: AdoptionOptimized mechanical structureThe product is designed to withstand mechanical and thermal stresses under a variety of operating conditions.

- High-quality materials: The key components are adoptedQuality materialsManufacturing, wear and corrosion resistance, extended service life

- Strict quality control: Quality control from raw materials to finished products to ensure that each motor meets the standard requirements.

3. Ease of maintenance

This series of motors has been designed with ease of maintenance in mind:

- modular design: Modularized design of key components to reduce maintenance difficulties and spare parts inventory

- Easily accessible structureRational structural design makes routine inspection, maintenance and overhaul work more convenient.

- Comprehensive monitoring interface: Can be customized according to user requirements, inInstall temperature monitoring devices on critical components such as stator windings and bearings.to monitor the motor's operating status in real time

VI. Installation and use guide

1. Installation environmental requirements

The YX series high-efficiency high-voltage three-phase asynchronous motors have specific requirements for the installation environment:

- environmental conditions: Suitable for use at altitudeNot exceeding 1000mAmbient temperature-15℃~+40℃working environment

- Applicable places: Indoor or outdoor, non-hazardous gas environments

- Specialized environmental adaptation: For special environmental conditions, customized designs can be provided to meet requirements

2. Installation and commissioning

Correct installation and commissioning is the key to ensure the normal operation of the motor:

- basic requirement: RequiredStrong and level foundationThe motor is designed to withstand the weight of the motor and the mechanical stresses of operation.

- alignment requirements: When the motor and driven machinery are connected by couplings, it must be ensured thatPrecise alignmentAvoidance of additional forces

- electrical connection: Follow the motor nameplate and wiring diagram for proper wiring to ensure thatreliable grounding

VII. Services and technical support

1. Quality assurance systems

Xima Electric has established a comprehensive quality assurance system to ensure the exceptional quality of its YX series high-efficiency high-voltage three-phase asynchronous motors:

- International Standard Certification: ByISO9001 Quality System CertificationSome of the products have passedCE marking和CCC Certification

- Strict testing process: In the manufacturing process afterMultiple rigorous testsEnsure that the performance of the product meets the requirements of the standard

- Comprehensive performance testing: Each motor isRigorous factory testingIncludes no-load test, load test and insulation withstand voltage test.

2. After-sales service commitments

Simo motors provide customers with comprehensive after-sales service guarantee:

- rapid response: Customers who find quality problems in the course of use, upon notification of the24-hour responseIf on-site service is requiredActivated within 48 hours

- Professional Support: Maintenance personnel will not be withdrawn until the fault is eliminated to ensure that the equipment is returned to normal operation

- Lifetime Service: Once a Simo motor product is soldLifetime Cost WarrantyProvide long-term technical support to customers

The YX series high-efficiency high-voltage three-phase asynchronous motors, with theirExcellent technical performance、Rugged structural design和Reliable operational performanceIt has become the industrial powerhouse of thePreferred Solution. Simo motors are available throughContinuous technological innovation和Strict quality controlEnsure that every YX series high-efficiency high-voltage three-phase asynchronous motor can operate atHarsh industrial environmentssubscribeStable and efficientThe power of the support.

Choosing the Xima YX Series High-Efficiency High-Voltage Three-Phase Asynchronous Motor means choosingReliable equipment performance和Complete technical servicesWe are looking forward to cooperating with you. We are looking forward to cooperating with you to jointly promote the progress and development of energy-saving technology in the industrial field.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206