Article Catalog[Hidden]

- YRQ Medium-Duty Asynchronous Motors: Efficient and Reliable Industrial Power Solutions

YRQ medium-sized asynchronous motorHigh-Efficiency, Reliable Industrial Power Solutions

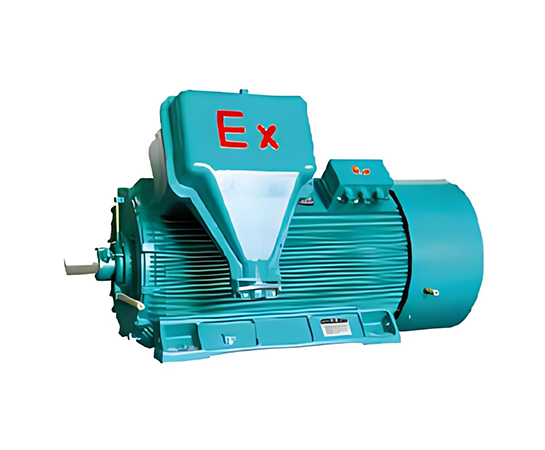

YRQ Medium-Duty Asynchronous Motors for Industrial Applicationscore power unit (CPU), with itssuperior performance和Reliable operating characteristicsThe YRQ medium-duty asynchronous motor has become the preferred drive solution for heavy-duty equipment across various industries. This article provides a comprehensive overview of its product features, technical specifications, and application fields.

Product Overview

The YRQ medium-sized asynchronous motor adoptsAdvanced Electromagnetic Design和Quality materialsManufactured three-phase wound-rotor asynchronous motors, featuringStructurally robust, operationally reliable, and easy to maintainThis series of motors strictly adheres toGB/T 13957-2022Large-scalethree-phase asynchronous motorNational Standards such as "Basic Series Technical Conditions"Its power ratings and mounting dimensions comply with internationally recognized standards, facilitating equipment compatibility and replacement.

act asIndustrial Power CoreThe YRQ series motors are suitable for driving various heavy-duty machinery and equipment, such asCompressor, water pump, crusher, coal mill, rolling mill, winch等. itsBox-type steel plate welded structureEnsures reliable operation under various environmental conditionsIt is the ideal prime mover for various industrial and mining enterprises such as mines, the machinery industry, the petrochemical industry, and power plants.。

Core Technical Features

1. High-efficiency energy-saving design

YRQ Medium-Duty Asynchronous Motors AdoptOptimized electromagnetic solutions和Low-loss materialsSignificant improvements in efficiency and notable energy-saving effects have been achieved. The power ratings and electrical performance of the motors comply with the national standard GB755 "Basic Technical Requirements for Rotating Electrical Machines" and the International Electrotechnical Commission (IEC) standards.Compared to conventional motors, it effectively reduces operating costs and shortens the payback period.

2. Excellent operating characteristics

- Wide speed adjustment rangeThe wound rotor structure enables the motor to haveSuperior starting performance and speed regulation capability

- Superior starting performance:High starting torquecapable of meeting heavy-duty starting requirements

- Low vibration and low noise: ByPrecision Manufacturing ProcessThe motor operates smoothly with low noise and minimal vibration.

3. Sturdy structural design

- High protection ratingThe enclosure protection rating can be achieved as required.IP23, IP44, IP54At different levels

- Quality Insulation Systems: AdoptionClass F or Class H insulationReliable insulation and long life

- Reinforced Bearing SystemBearings haveRolling bearings and sliding bearingsDepending on the motor's power rating and rotational speed.

Technical Parameters and Specifications

The YRQ medium-sized asynchronous motor covers a wide range of technical specifications to meet the power requirements of various industrial applications. Below are the key technical parameters for this series of motors:

Description of performance characteristics

YRQ Series Motors inElectromagnetic design, structural strength and thermal performanceAll aspects have been fully optimized:

- High-efficiency operating rangeThe motor maintains high efficiency across a wide load range, outperforming traditional motors.Significant efficiency gainsEnergy saving is obvious

- Wide Voltage Adaptability: the ability toDifferent voltage levelsMaintain stable performance and adapt to various grid environments.

- high power factorOptimized design enables the motor to haveHigher power factorImprove grid quality and reduce investment in reactive power compensation equipment.

Structural Design and Configuration

1. Motor body structure

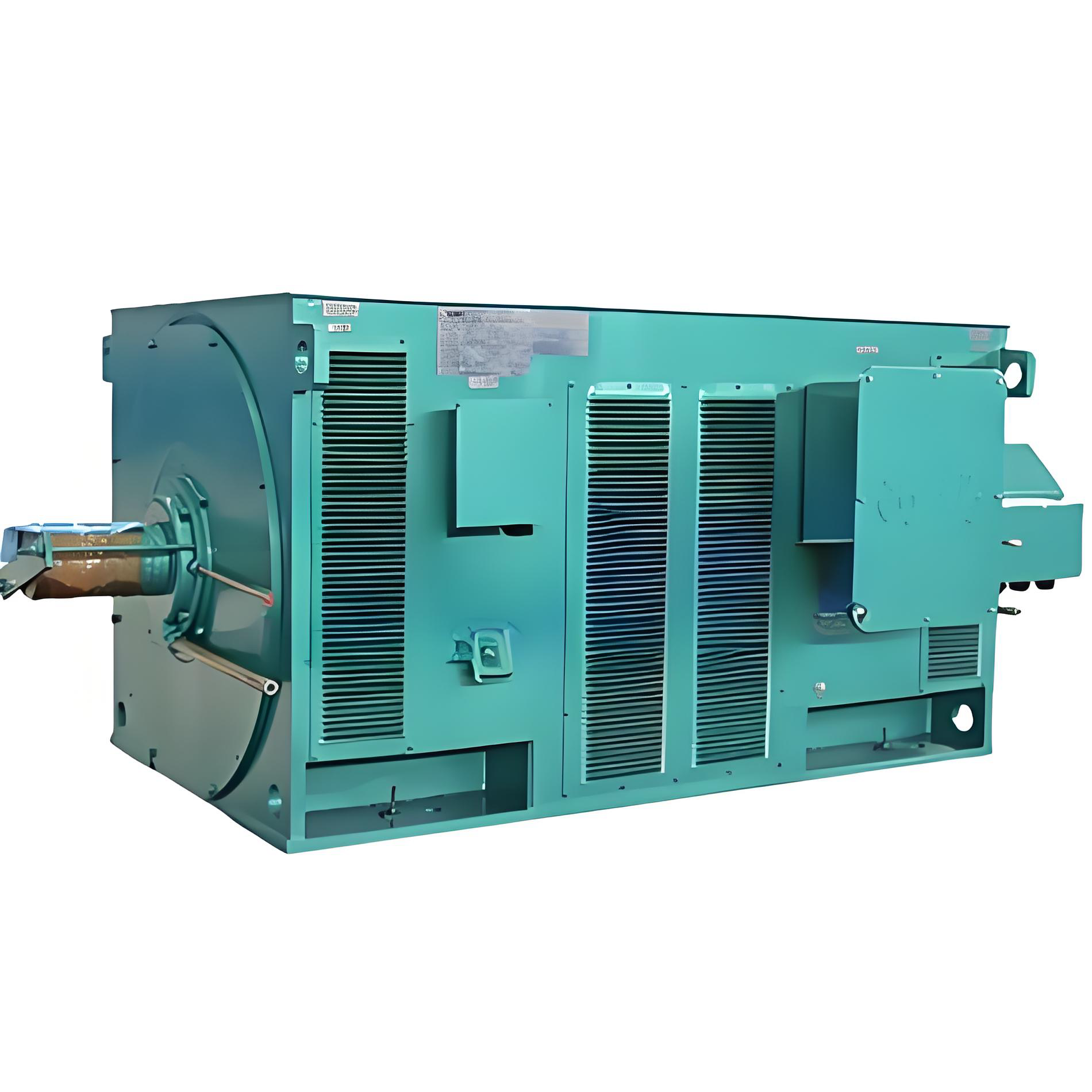

YRQ Medium-Duty Asynchronous Motors AdoptBox-type structural designEach component is carefully designed and optimized:

- Stand design: AdoptionWelded from steel platesLightweight and rigidThe sides and top of the motor base feature window openings that can accommodate protective covers or plates. Removing these covers or plates allows access to observe and reach the motor's internal components, facilitating maintenance and repair.

- Stator structureThe stator adoptsExternal Pressure Assembly StructureThe stator windings adoptClass F Insulation MaterialThe ends are securely fastened and tied.During the manufacturing process, multiple inter-turn pulse voltage tests and ground withstand voltage tests were conducted, andVacuum Pressure Impregnation (VPI) Process for Solvent-Free Coatings ProcessingTherefore, the motor features excellent and reliable insulation performance, high mechanical strength, and strong moisture resistance.

- Rotor construction: The rotor isWound rotor with slip ring structureThe wound rotor adoptsClass F Insulation MaterialVacuum Pressure Impregnation (VPI) Treatment with Solvent-Free Coatings

2. Cooling system

YRQ Series Motors ProvideMultiple cooling methodsEnsure the motor operates continuously and stably under rated load:

- IC01 Cooling MethodYR series motors with IP23 protection rating utilize this cooling method.

- Cooling Method for IC611YRKK series motors with air-to-air cooling in a closed configuration and IP44 protection rating utilize this cooling method.

- IC81W Cooling MethodThe YRKS series motors, featuring air-water cooling in a sealed configuration and an IP44 protection rating, utilize this cooling method.

Application Areas and Scenarios

YRQ medium-sized asynchronous motors are widely used across numerous industrial sectors due to their reliable performance and energy-efficient characteristics:

1. Heavy industry

- Mining industry: for drivingCrusher, Coal Mill, WinchHeavy equipmentWithstands harsh operating conditions

- Steel Metallurgy: Applied toRolling mill, blowerand other equipment, providing reliable power support

- Power industry: forpower plantsvarious auxiliary equipment

2. General industrial areas

- Compressor and pump equipment: Applicable toCompressors, pumpsand other equipment, providing efficient power solutions

- transmission mechanism: Applied toTransportation machinery, conveyor beltsMaterial handling equipmentMeet the requirements for continuous operation

- cutting machine: for all kinds ofMachine Toolsthe driver

3. Special application scenarios

YRQ series motors are particularly suitable for the following special operating conditions:

- Requires a high starting torquethe occasion

- The transmission line capacity is insufficient to start the squirrel-cage motor.the situation

- Long startup time and frequent startupsspecifications

- Requires fine-tuning of speedapplication

Product Advantages and Value

1. Operational reliability

The YRQ series motors offer distinct advantages in reliability:

- Rugged structural design: AdoptionBox-type steel plate structureThe product is designed to withstand mechanical and thermal stresses under a variety of operating conditions.

- High-Quality Materials and Manufacturing: The key components are adoptedQuality materials和Precision Manufacturing ProcessEnsure long-term stable operation of the motor.

- Comprehensive protection design:Both the stator and bearings are equipped with PT100 temperature sensors.Enhanced the motor's inherent protection capabilitiesAll electric motor bearings haveNon-stop oil injection and drainage device

2. Energy efficiency economics

YRQ series motors offer significant economic benefits:

- Reduced operating costs: High-efficiency design can beSignificant reduction in energy consumptionReduced payback period

- Optimizing energy use: The motor hasHigher power factor and efficiencyImprove grid quality and reduce investment in reactive power compensation equipment.

- Low life cycle costs:Long life design和Low maintenance requirementsDramatic reductions in total life cycle costs

3. Ease of maintenance

This series of motors has been designed with ease of maintenance in mind:

- Maintenance-friendly structural design:Removing the cooler or protective cover allows observation and access to the motor's interior.for easy installation and maintenance of the motor

- modular design: Modularized design of key components to reduce maintenance difficulties and spare parts inventory

- Long life design: AdoptionQuality Insulation SystemsLong design life, long maintenance intervals

Installation and User Guide

1. Installation environmental requirements

The YRQ medium-sized asynchronous motor has specific requirements for the installation environment:

- environmental conditionsApplicable to ambient air temperature-15°C to +40°Cworking environmentin environments free of severe dust, corrosive gases, and explosive gases

- altitudeInstallation AltitudeNot exceeding 1000m

- mounting positionThe basic installation method for electric motors isHorizontal with Base Angle (IMB3)

2. Installation and commissioning

Correct installation and commissioning is the key to ensure the safe operation of the motor:

- basic requirement: RequiredStrong and level foundationThe motor is designed to withstand the weight of the motor and the mechanical stresses of operation.

- alignment requirements: When the motor and driven machinery are connected by couplings, it must be ensured thatPrecise alignmentAvoidance of additional forces

- electrical connection: Properly wire the motor in accordance with the motor nameplate and wiring diagram to ensure that thereliable grounding

Service and Technical Support

1. Quality assurance systems

The production of YRQ medium-sized asynchronous motors adheres to strict quality standards:

- standards compliance: The products strictly follow theGB/T 13957-2022、GB755National standards and international standards

- Strict testing process: In the manufacturing process afterMultiple Turn-to-Turn Impulse Voltage Tests and Withstand Voltage Tests to GroundEnsure that the performance of the product meets the requirements of the standard

- Comprehensive performance testing: Each motor isRigorous factory testingEnsure reliable product quality

2. After-sales service commitments

The supplier provides customers with comprehensive after-sales service support:

- Professional Technical Support: Provide professional consulting services for product selection and installation guidance

- Rapid Response Mechanism: Respond to and resolve customer issues in a timely manner upon receipt of after-sales service requests

- Ongoing services: Provide customers with long-term technical support and service guarantee

YRQ medium-sized asynchronous motors, with theirExcellent technical performance、Highly efficient energy-saving features和Reliable operational performanceIt has become the industrial powerhouse of theIdeal Solution. ByContinuous technological innovation和Strict quality controlEnsure that every YRQ series motor can operate inHarsh industrial environmentssubscribeSafe, stable and efficientThe power of the support.

Choosing the YRQ medium-sized asynchronous motor means choosingReliable equipment performance和Complete technical servicesWe are looking forward to cooperating with you. We are looking forward to cooperating with you to jointly promote the progress and development of energy-saving technology in the industrial field.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206