Article Catalog[Hidden]

- Professional Interpretation of the YBBP Series Explosion-Proof Three-Phase Asynchronous Motors for Underground Coal Mines

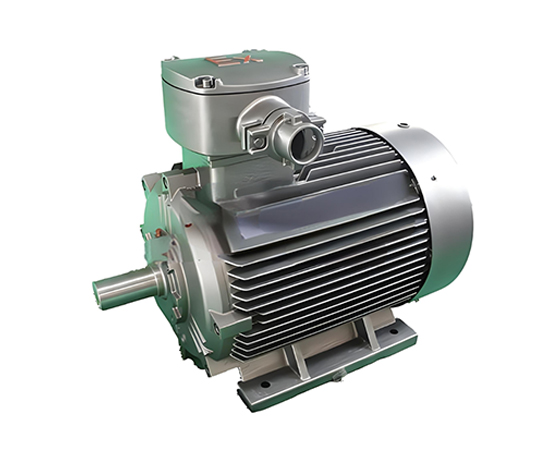

YBBP Series Explosion-Proof Type for Underground Coal Minesthree-phase asynchronous motorProfessional Interpretation

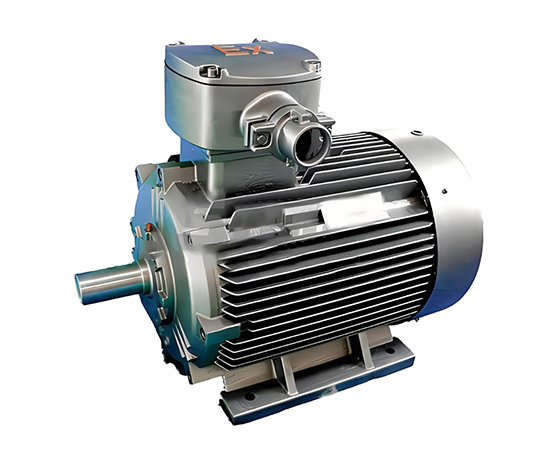

In the coal mining sector, the YBBP series explosion-proof three-phase asynchronous motors are characterized by theirOutstanding explosion-proof performance和Flexible speed regulation characteristicsbecoming an indispensable power unit in underground working environments.

YBBP Series Explosion-proof Three-phase Asynchronous Motors for Underground Coal MinesSpecifically designed for underground coal mining conditionsExplosion-Proof Power Equipment with Variable Frequency Speed ControlThis series of motors adoptsAdvanced explosion-proof technology and variable frequency speed control designpossessExplosion-proof safety, wide speed range, reliable operation, energy-efficient and high-performancefeatures, strictly adhering toGB 3836.1-2010 "Explosive Atmospheres - Part 1: Equipment - General Requirements" 和GB 3836.2-2010 Explosive Atmospheres - Part 2: Equipment Protected by Flameproof Enclosures "d" National Standards。

I. Product overview and technical characteristics

1. Product Positioning and Scope of Application

The YBBP Series explosion-proof three-phase asynchronous motors are specifically designed forHarsh working conditions in coal mine shaftsDesigned for specific purposesVariable Frequency Drive MotorIts explosion-proof rating isEx d I MbApplicable toUnderground coal mines containing gases such as methane or coal dust (non-mining areas) and factoryContains Class IIA, Grade B T1–T4 groupsLocations where explosive mixtures of flammable gases or vapors may form。

When used in conjunction with a variable frequency drive, this series of motors can achieveSmooth stepless speed adjustment over a wide range, inSpeed regulation range, dynamic response, speed regulation accuracy, low-frequency torque, slip compensation, power factor, efficiencyin all aspects。

2. Core technical characteristics

The YBBP series motors incorporate multiple innovative technologies and offer significant performance advantages:

- Outstanding explosion-proof designThe motor's explosion-proof structure is advanced. When an explosive mixture inside the motor detonates,The explosion-proof enclosure effectively prevents explosions from propagating to the external environment.

- Wide speed adjustment range:Frequency range5–50 Hz operates in constant torque mode, while 50–100 Hz operates in constant power mode.Some models can reach3 Hz–60 Hz或3(5)~60Hz (2-pole)、3(5) to 100 Hz (4 poles and above)

- Special Insulation System: AdoptionInsulating Materials and Processes Resistant to High-Frequency Pulse Voltage SurgeThe stator windings adoptClass F insulation systemWhen the motor operates at the minimum airflow within the specified operating conditions, the allowable bearing temperature shall not exceed95°CThe maximum surface temperature of the enclosure shall not exceed150°C

Technical parameters and performance indicators

The YBBP series explosion-proof three-phase asynchronous motors offer comprehensive technical advantages. Below are their primary technical specifications:

Main technical parameters

Description of performance characteristics

The YBBP series motors areExplosion-proof safety, operational performance, and speed regulation characteristicsExcellent performance in all areas:

- high efficiency and energy saving: For use with variable frequency drives,More significant energy-saving effects

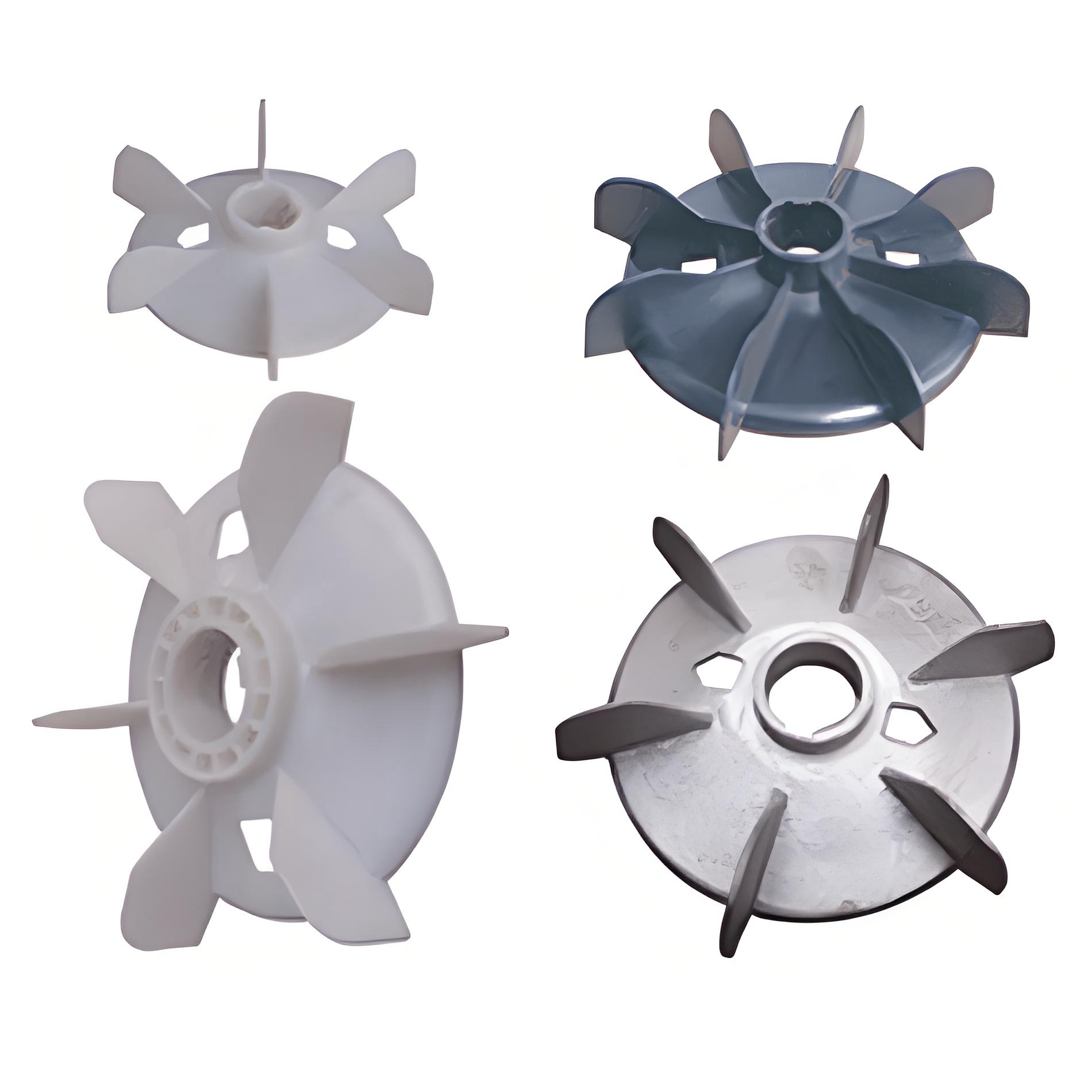

- Independent cooling system: AdoptionIndependent fan forced-air coolingEnsure effective heat dissipation even when the motor operates at low speeds.

- Low vibration and low noise: AdoptionOptimized design and precision manufacturing processesThe motor operates smoothly, with vibration and noise effectively controlled.

III. Structural design and configuration

1. Motor body structure

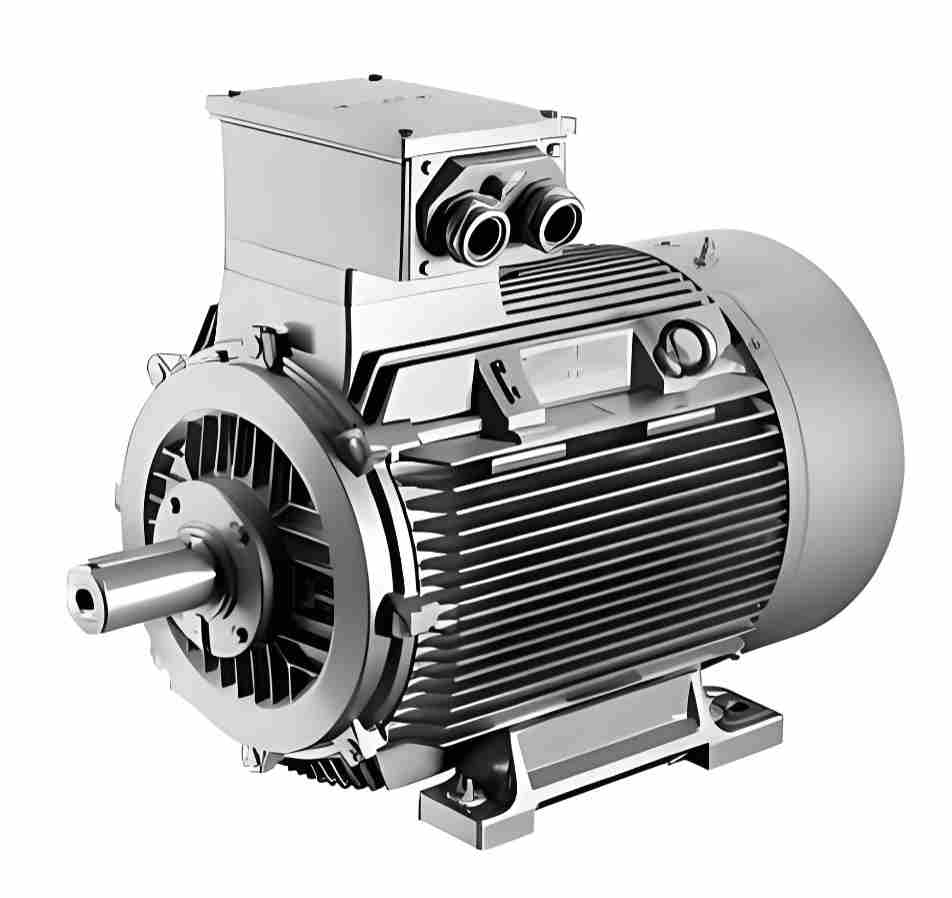

The YBBP Series Explosion-Proof Three-Phase Asynchronous Motors adoptProfessional Explosion-Proof DesignEach component is carefully designed and optimized:

- Explosion-proof enclosure designThe structural design of the explosion-proof enclosure for electric motors complies with explosion-proof standards, capable of withstanding internal explosion pressure without damage.

- Cooling System Design: AdoptionIC416 Cooling Method (Forced Ventilation)equipped withIndependent Fan Forced Ventilation Cooling SystemEnsure that the motor receives sufficient cooling airflow even during low-speed operation.

- Junction Box DesignThe junction box featuresProfessional explosion-proof constructionThe box features a large internal cavity for convenient wiring and offers multiple cable entry options.

2. Internal Core Components

The internal structure of the YBBP series motors has been meticulously designed and optimized to ensure efficient and safe operation:

- Stator winding: AdoptionSpecial Insulation Systembe able toResistant to high-frequency pulse voltage surgesReliable insulation and long life

- Rotor designThe rotor adoptsHigh-quality materials和Precision Manufacturing ProcessExcellent dynamic balancing performance ensures smooth and reliable operation of the motor across the entire speed range.

IV. Application areas and scenarios

The YBBP series explosion-proof three-phase asynchronous motors are widely used in the coal mining industry due to their reliable explosion-proof performance and excellent speed regulation characteristics:

1. Underground mining equipment

- Fixed Equipment in Coal Mine Underground: for drivingUnderground coal mines (non-mining work areas) fixed equipmentsuch as pumps, fans, and other equipment

- Mining Transportation Machinery:For use in coal mine shaftsConveyors, hoistsEquipment such as explosion-proof motors and variable speed drives provide reliable explosion-proof power and speed control.

2. Applicable Environmental Conditions

The YBBP series motors have a clearly defined operating environment range:

- environmental temperatureAmbient air temperature is-15°C to +40°C(The maximum depth underground in coal mines is)35°C)

- altitudeInstallation AltitudeNot exceeding 1000m

- humidity conditionThe maximum relative humidity of ambient air shall not exceed95%(At a temperature of +25°C)

V. Product Advantages and Values

1. Safety and Reliability

The YBBP series explosion-proof three-phase asynchronous motors offer significant advantages in terms of safety:

- Reliable explosion-proof performance: Strictly in accordance withNational Explosion-Proof StandardsDesigned and manufactured with advanced explosion-proof construction to ensure safe operation in explosive environments.

- High-Quality Materials and Manufacturing: The key components are adoptedQuality materials和Precision Manufacturing ProcessEnsure long-term stable operation of the motor.

- Professional cooling systemIndependent forced-air cooling system ensures effective heat dissipation even during low-speed operation.

2. Operational Efficiency

The YBBP series motors deliver significant operational benefits:

- Reduced operating costs: Excellent speed regulation performance enablesSignificant reduction in energy consumptionReduced payback period

- Optimize Process ControlThe wide speed range enables the equipment to operate at the optimum operating point, enhancing production efficiency.

- Low life cycle costsAlthough the initial investment may be slightly higher,Energy-saving benefits during operation and low maintenance costsDramatic reductions in total life cycle costs

3. Ease of maintenance

This series of motors has been designed with ease of maintenance in mind:

- Maintenance-friendly structural designRational structural design makes routine inspection, maintenance and overhaul work more convenient.

- modular design: Modularized design of key components to reduce maintenance difficulties and spare parts inventory

- Long life design: AdoptionClass F insulation systemLong design life, long maintenance intervals

VI. Installation and use guide

1. Installation environmental requirements

The YBBP series explosion-proof three-phase asynchronous motors have specific requirements for the installation environment:

- environmental conditions: Applicable toUnderground coal mines containing gases such as methane or coal dust (non-mining areas) Environment

- altitudeInstallation AltitudeNot exceeding 1000m

- mounting positionEnsure sufficient space around the motor for cooling ventilation and maintenance.

2. Installation and commissioning

Proper installation and commissioning are critical to ensuring the safe operation of the motor:

- electrical connection: Follow the motor nameplate and wiring diagram for proper wiring to ensure thatreliable grounding

- Cooling System InspectionEnsure the independent fan operates normally and provides adequate ventilation.

- Variable Frequency Drive MatchingSelect the appropriate variable frequency drive and configure parameters according to the motor's speed regulation characteristics.

VII. Services and technical support

Professional manufacturer of YBBP series explosion-proof three-phase asynchronous motors provides customers with comprehensive services and technical support:

- Professional Technical Support: Provide professional consulting services for product selection and installation guidance

- Rapid Response Mechanism: Respond to and resolve customer issues in a timely manner upon receipt of after-sales service requests

- Ongoing services: Provide customers with long-term technical support and service guarantee

The YBBP series explosion-proof three-phase asynchronous motors for underground coal mines, with theirOutstanding explosion-proof performance、Excellent speed regulation characteristics和Reliable operational performancehas become the industrial power solution for hazardous environments in coal mine shafts.Ideal Solution. ByContinuous technological innovation和Strict quality controlEnsure that every YBBP series motor can operate atHarsh coal mine environmentsubscribeSafe, stable and efficientThe power of the support.

Choosing the YBBP series explosion-proof three-phase asynchronous motors for underground coal mines means choosingReliable security assurance和Complete technical servicesWe look forward to collaborating with you to advance safety production and energy-saving technological progress in the coal mining industry.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206