Article Catalog[Hidden]

- G Series Variable Frequency Fans: High-Efficiency, Energy-Saving Smart Ventilation Solutions

G Series Variable Frequency Fans: High-Efficiency, Energy-Saving Smart Ventilation Solutions

In the modern industrial sector, the G Series variable frequency fans are characterized by theirOutstanding energy-saving performance和Precise airflow controlis becoming a core component for ventilation and heat dissipation in various industrial equipment.

G series inverter fanSpecifically designed for variable frequency drive motorsHigh-efficiency cooling equipmentstrictly adhere toGB/T 22712-2021《Variable Frequency MotorNational Standard for Technical Specifications of G Series Cooling FansThis series of fans employsAdvanced aerodynamic design和Manufactured from premium materialsprimarily used in power supplies for variable frequency drivesYVF2 Series Dedicated Variable Frequency Speed Controlthree-phase asynchronous motorcooling systempossessHigh efficiency, low noise, compact structure, easy installationand other technical features.

As a key component of variable-frequency motors, the G-series variable-frequency fans achieveIntelligent Airflow Adjustment和High-efficiency heat dissipation performanceEnsure the motor maintains optimal operating temperature under various working conditions, therebyExtend equipment service life,Reduce system energy consumptionProvide reliable technical support to help enterprises achieve their energy-saving and consumption-reduction goals.

I. Core Technical Features

1. High-efficiency energy-saving design

The G Series variable frequency fan incorporates multiple innovative designs to ensure outstanding performance in both energy efficiency and operational capabilities:

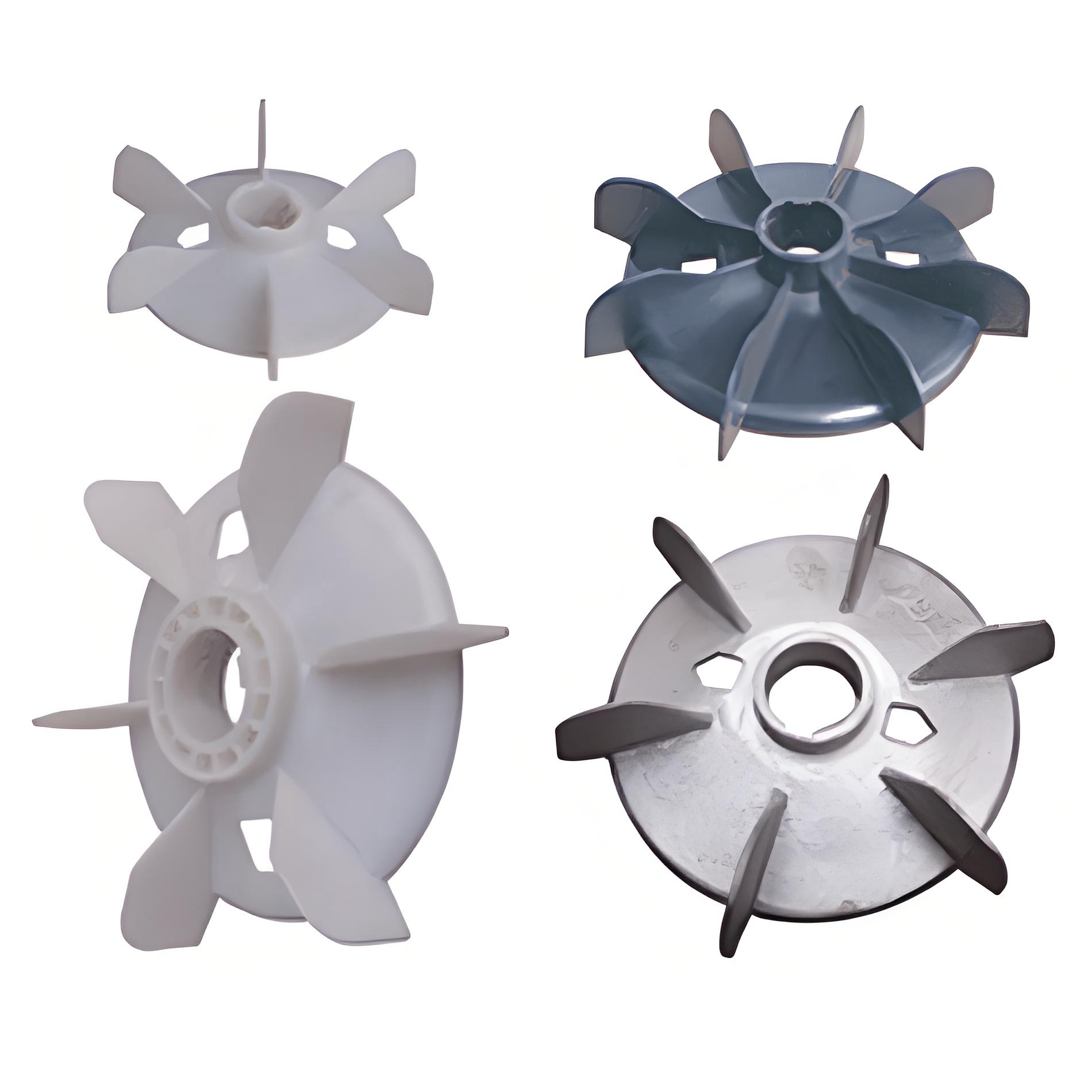

- Optimize blade design: AdoptionPrecision-calculated blade angles and curved surface shapesThis design ensures smoother and more concentrated airflow, significantly enhancing air volume output efficiency. Taking the G180 model as an example, its air volume can reach1300 m³/hwhile power consumption is only80W

- High-efficiency motor configuration: Equipped withSpecialized Variable Frequency Drive MotorIt maintains high efficiency across varying rotational speeds, eliminating the energy loss associated with traditional fans when adjusting airflow.

- Intelligent Wind Speed AdjustmentBased on the actual heat dissipation requirements of the motorAutomatically adjusts rotational speedAvoid energy waste caused by excessive ventilation, significantly reducing system operating costs.

2. Low-noise operation technology

The G Series variable-frequency fans incorporate multiple innovative technologies for noise control:

- Pneumatic Noise Optimization: BySpecial impeller design and duct optimizationReduce airflow turbulence and vortex formation to minimize noise at its source.

- Vibration Control Technology: AdoptionHigh-Precision Dynamic Balancing CorrectionEnsure smooth operation of the fan to minimize structural noise caused by vibration.

- Application of Soundproofing Materials:Key areas utilizeSound-absorbing materialFurther blocking noise transmission ensures quieter equipment operation. The G180 model maintains noise levels within60 dBBelowSuperior to similar products

3. Sturdy and durable construction

The G Series variable frequency fans emphasize long-term reliability in both structural design and material selection:

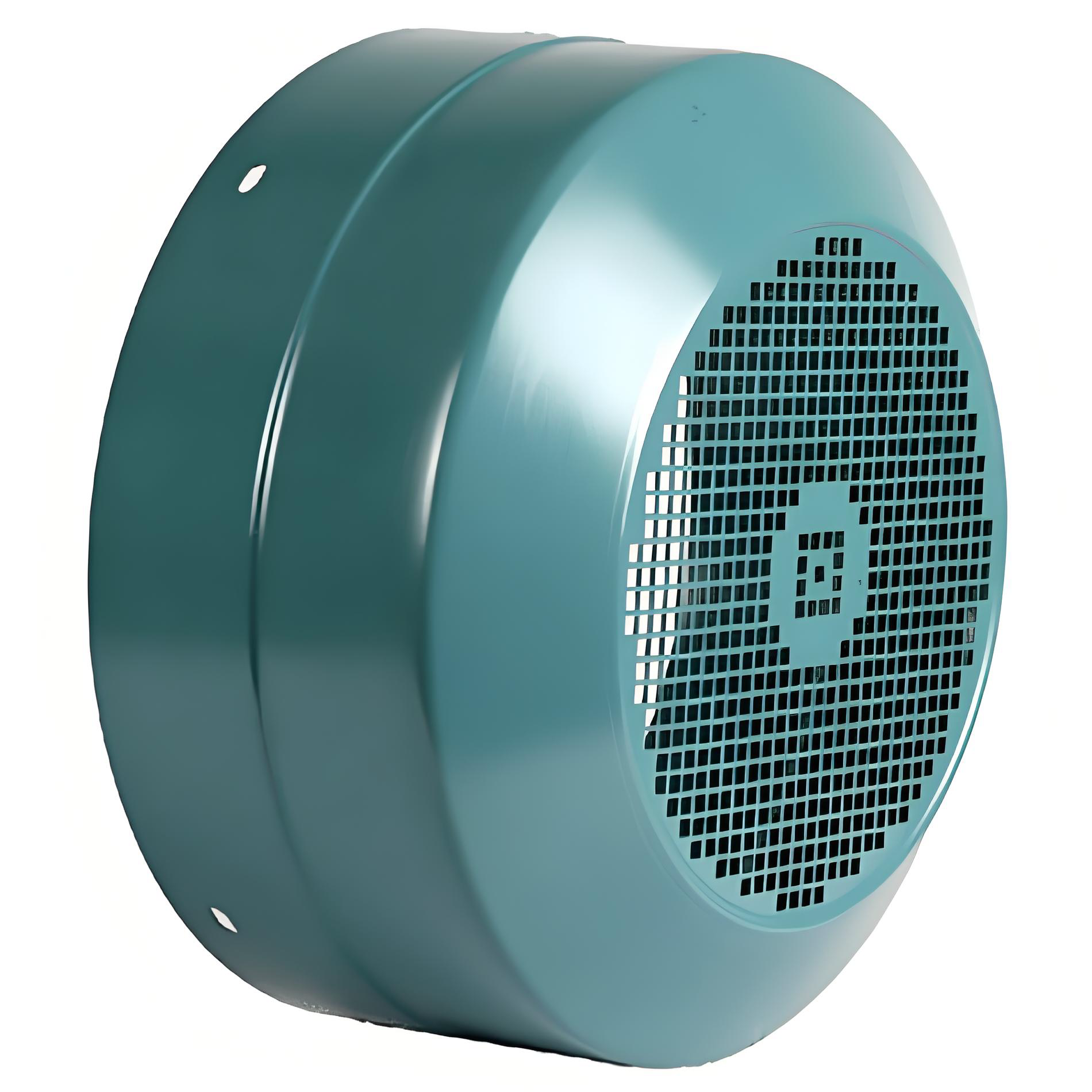

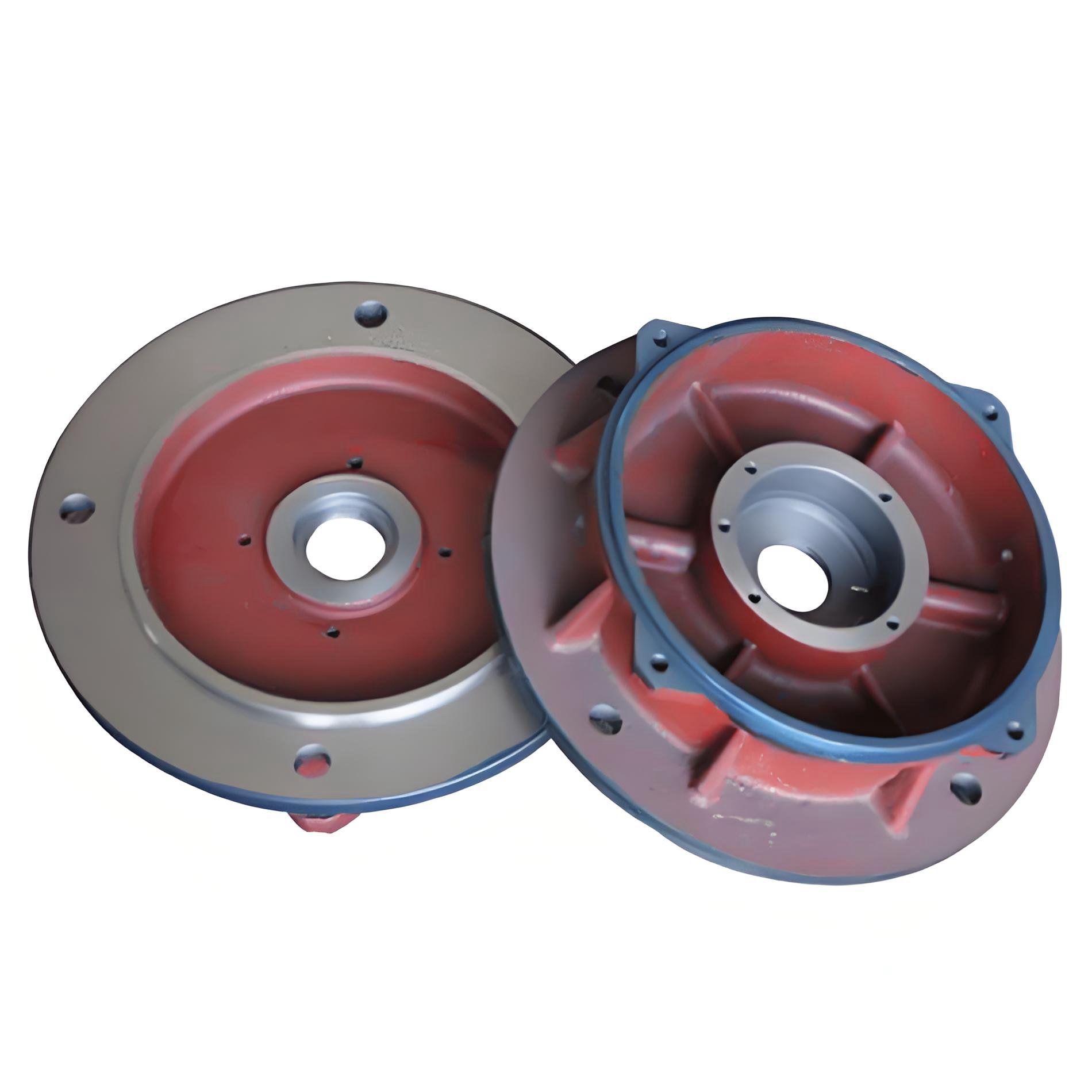

- Premium Material SelectionThe fan housing is made ofHigh-strength iron shellcombining excellent structural strength with superior heat dissipation performance

- High protection ratingStandard product protection rating reachesIP55Effectively prevents dust ingress and water spray, suitable for harsh industrial environments.

- Excellent temperature resistance: the ability toAmbient temperature shall not exceed 40°C.Stable operation under high-temperature conditions, suitable for high-temperature industrial environments

II. Technical Parameters and Specifications

The G Series variable frequency fans offer multiple specifications and models to meet the needs of various application scenarios. Below are the technical parameters for typical models:

In addition to standard specifications, the G Series variable-frequency fans can also be customized with multiple options to meet user requirements:

- InstallationIn addition to standard horizontal installation, it can also beForm a vertical structure with a rain coverAdapt to different installation environments

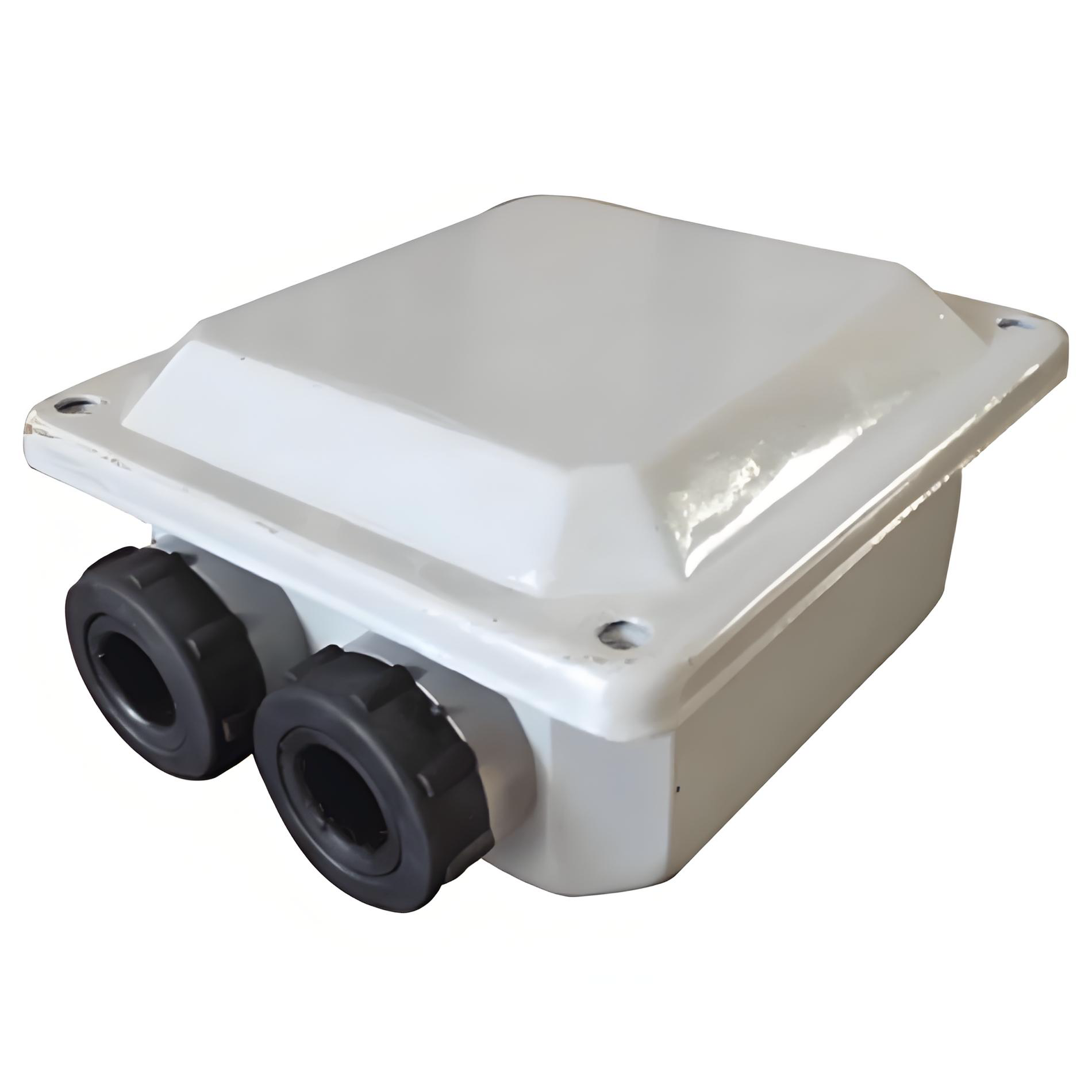

- Qualification methodIn addition to the standard right-side cable outlet, we can also provideLeft-side wiring, top-side wiringStructures that facilitate on-site wiring

- Additional Features:CanInstall additional components such as brakes and encodersto achieve more complex control functions

III. Application Domains and Scenarios

The G Series variable frequency fans, with their reliable performance and flexible control features, are widely used across numerous industrial sectors:

1. Industrial Manufacturing Sector

- Variable Frequency Drive Motor: Specifically designed forYVF2 Series Three-Phase Asynchronous Motors for Variable Frequency Speed ControlDesign and provide precisely matched cooling solutions

- Heavy machinery and equipment: Applicable toMining machinery, metallurgical equipmentMeet the heat dissipation requirements of high-power motors to ensure stable operation of equipment under heavy-load conditions.

- Production line equipmentforMachine tools, conveyor systems, automated production linesThe drive motor provides reliable cooling, enhancing production continuity.

2. Infrastructure Sector

- HVAC System: Applied toChillers, Air Handling Units, Fan Coil Unitsequipment, enabling on-demand adjustment to reduce system energy consumption

- Water Treatment System: Applicable toPump, FanEnsure the cooling of equipment to meet the continuous operation requirements of the water treatment industry.

- Power facilitiesforGenerator sets, power transformation equipmentProvides forced cooling to ensure stable operation of the power system.

3. Special Environment Applications

- Highly dusty environmentsThe high protection rating design enables it to operate inBuilding materials, cementReliable operation in environments with high dust levels

- high temperature environment: the ability toHigh-temperature workshop, heat treatment equipmentMaintain good performance in such environments

- humid environmentExcellent sealing performance adapts toUnderground engineering, offshore platformsIn humid environments

IV. Product Advantages and Value

The G Series variable frequency fans deliver multiple technical advantages and economic benefits to users:

1. Energy Conservation and Consumption Reduction Benefits

- Adjust airflow as neededBased on the actual temperature of the motorAutomatically adjust cooling airflowAvoid energy waste caused by excessive ventilation.

- Optimal operating point:Maintains high efficiency across a wide speed range, compared to traditional fixed-speed fansEnergy Saving 20%-40%

- Reduce system operating costsReducing energy consumption directly lowers a company's electricity usage and shortens the payback period for equipment investments.

2. Equipment Protection Value

- Maintain motor temperatureEnsure the motor isOperates within the optimal temperature rangeDelay the aging of insulating materials and extend the service life of motors.

- Reduce thermal stress impactThrough stable temperature control, prevent the motor fromSudden temperature changeresulting in thermal stress damage

- Enhance system reliabilityStable heat dissipation conditions reduce the risk of motor failure due to overheating, enhancing the reliability of the entire production system.

3. Ease of Installation and Maintenance

- Compact structure:Exquisitely designed,Compact designfor easy installation in space-constrained equipment

- Standardized interfaces: Utilizes standard installation dimensions and interfaces, compatible withMultiple models of variable frequency motorsDirect fit, reducing modification work

- Simple maintenance:modular designMake routine inspections and maintenance more convenient, reducing maintenance costs and time.

V. Selection and Installation Guide

1. Selection Criteria

Selecting the appropriate G-series variable frequency fan requires comprehensive consideration of the following factors:

- Motor Power MatchingBased on the motor requiring coolingPower and heat outputSelect the appropriate fan model with the required airflow capacity.

- Installation space limitationsMeasure the available installation space to ensure the fan can be installed.Installed successfully with sufficient intake air space

- environmental conditions:Consider the environmentTemperature, humidity, dust concentrationfactors, determine the appropriate protection rating

- Control RequirementsBased on the required temperature control accuracy, determine whether a temperature controller is needed.Smart Temperature Control System

2. Installation Notes

Proper installation is key to ensuring the fan operates normally:

- Solid foundationEnsure the installation foundationFlat and sturdyAvoid noise and damage caused by vibration.

- Airflow is unobstructedThe air intake and exhaust ports of the fan should be kept clear.UnimpededAvoid obstacles that impede airflow.

- electrical connectionConnect the power and control wires correctly according to the wiring diagram, paying attention toreliable groundingprevent electrical faults

VI. Maintenance and Troubleshooting

1. Key Points for Regular Maintenance

Maintenance tasks for G-series variable-frequency fans primarily include:

- Cleanliness Inspection: PeriodicallyRemove accumulated dust from the blades and air ducts.Maintain good heat dissipation performance

- Tightness Inspection: InspectionInstallation bolts and terminal blocksCheck for looseness and ensure a secure connection.

- Bearing Maintenance: Periodically based on usage timeAdd or replace greaseEnsure long-term stable operation of the bearings.

2. Common Troubleshooting

Common Issues and Solutions Encountered During Fan Operation:

- Airflow reduced: InspectionDust accumulation on blades和Motor speedClean the blades or check the power supply voltage.

- Abnormal Vibration: InspectionAre the fasteners loose?、Is the impeller balance compromised?Tighten or replace as necessary

- The motor is not turning.: InspectionPower Supply和Control signalTroubleshoot electrical circuit faults

VII. Service and Support

Simo motorsComprehensive technical support and service assurance for G-series variable-frequency fan users:

- Technical Consultation:Provide professional consulting services for product selection and application solutions

- Customized Solutions: Tailored to meet specific user requirementsPersonalized Design and Manufacturing Services

- Perfect after-sales protection: Provide quality assurance and after-sales service to ensure worry-free use by customers

- Rapid Response MechanismEstablish an efficient supply chain and service network to ensure timely product delivery and rapid resolution of technical issues.

The G Series variable frequency fans, with theirAdvanced technical design、Reliable performance quality和Significant energy savingshas become the standard solution for cooling variable-frequency motors in modern industrial applications.Ideal ChoiceWith the continuous increase in industrial energy efficiency requirements and the widespread application of variable frequency technology, the G Series variable frequency fans willMore industries and scenariosDemonstrate its value in practice, creating benefits for industrial enterprises.Greater economic and social benefits。

Choosing Xima Motor's G Series Variable Frequency Fans means choosingHigh-efficiency cooling solution和Reliable Quality AssuranceWe look forward to collaborating with you to advance energy efficiency and green development in industrial equipment.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206