How to choose between 6kV and 10kV high voltage motors? An article to understand the insulation level and starting method difference

Date: 2025-11-30 Categories: Faq Views: 3343

Article Catalog[Hidden]

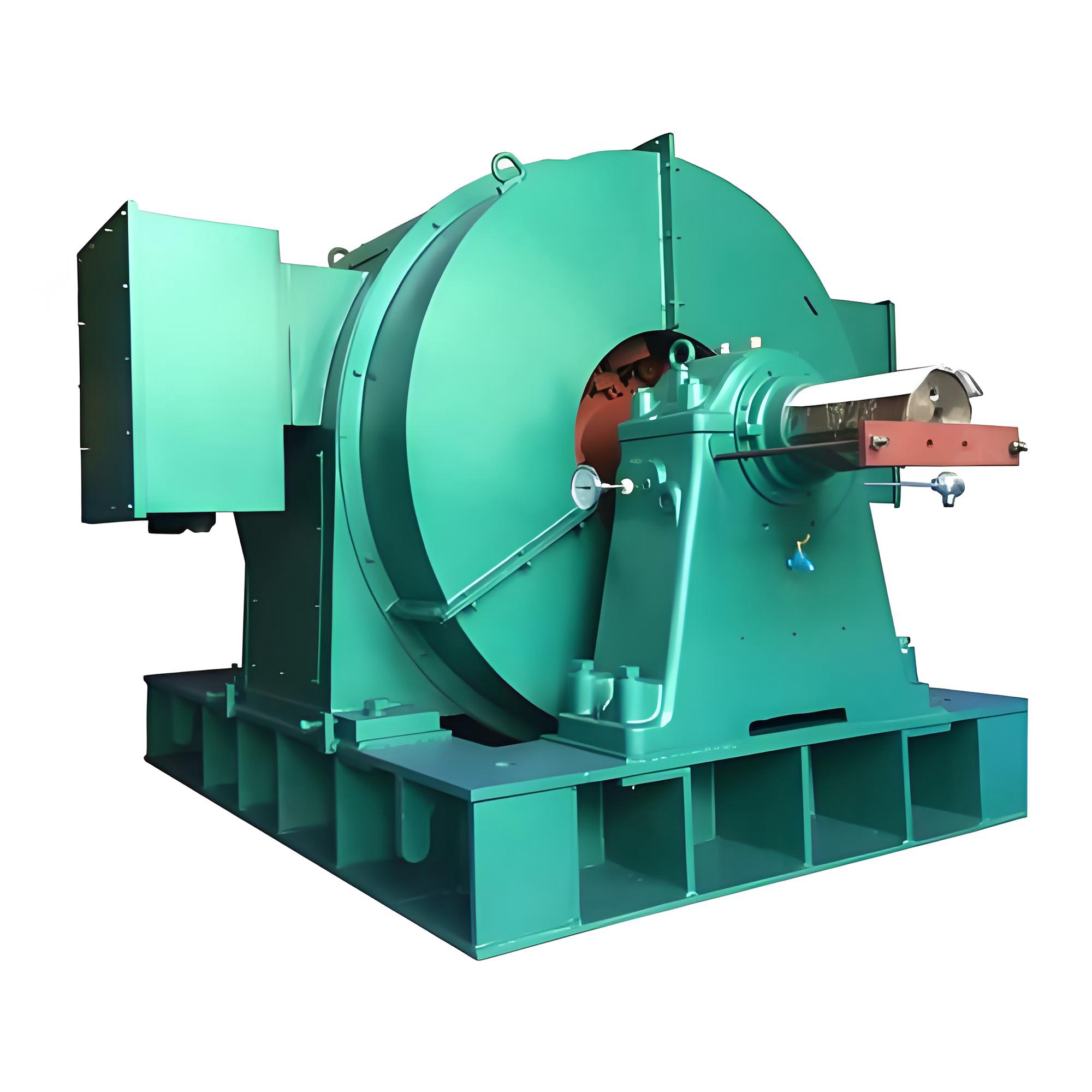

High voltage motorsTypically refers to motors with rated voltages of 3000V, 6000V (6kV), or 10000V (10kV) and above. Compared to low-voltage motors, the core advantage of high-voltage motors lies inLower current at the same powerThis significantly reduces stator copper losses and transmission line losses, making it suitable for driving high-inertia loads ranging from 200 kW to over 10,000 kW. The key to determining the quality of a high-voltage motor lies not in its appearance, but in the corona resistance of its insulation system and the integrity of its VPI vacuum impregnation process.

Core Technology Analysis: More Than Just Voltage Enhancement

High-voltage motors are not simply scaled-up versions of low-voltage motors; their manufacturing processes differ fundamentally. As procurement or engineering personnel, you must pay attention to the following critical parameters:

The Insulation System

F-class or H-class insulation must be used. Premium manufacturers employ low-resin mica tape for wrapping and undergo fully automated VPI (Vacuum Pressure Impregnation) treatment.

- Hard metrics: The coil must incorporate corona protection, particularly at the slots and ends. Otherwise, during prolonged operation, the high-voltage electric field will ionize the air and corrode the insulation layer, leading to breakdown to ground.

Cooling Method (IC Code)

- IC611 (Air-to-Air Cooling): Equipped with a heat exchanger at the top, suitable for harsh environments with high dust levels (such as cement plants and mines).

- IC81W (Air/Water Cooled): Higher efficiency and lower noise, but a reliable circulating cooling water system must be available on-site.

- IC01 (Open Type): Suitable only for extremely clean indoor environments; offers the lowest price but poor protection.

Bearing Structure

High-voltage motor shaft currents are an invisible killer. For high-power motors (typically 500 kW and above), the non-drive-end bearings must employ an insulated structure or be fitted with grounding carbon brushes to prevent shaft currents from causing electrolytic corrosion of the balls and raceways.

Application Scenarios and Selection Pitfalls (Manufacturer Insights)

High-voltage motors are primarily used in the power, mining, metallurgical, and petrochemical industries to drive fans, pumps, compressors, and crushers. However, in practical applications, we have observed that customers frequently make the following mistakes:

- Ignoring starting torque multiplier: Many fan loads exhibit high inertia. If standard-torque squirrel-cage motors (YKK series) are selected, this may result in excessively long start-up times or even stall-induced burnout. For heavy-load start-ups (such as ball mills), wound-rotor motors (YRKK series) must be used, or manufacturers must be requested to specially design rotor slot profiles to enhance stall torque.

- Altitude-related capacity reduction calculation error: Standard motor designs are intended for altitudes below 1000 meters. If the project is located in a high-altitude region, the thin air will result in reduced heat dissipation and insufficient insulation clearance.

- Avoid Pitfalls Guide: For every 100-meter increase in altitude, the temperature rise limit must be adjusted, and high-altitude (TH) high-voltage motors must be selected to increase electrical clearance.

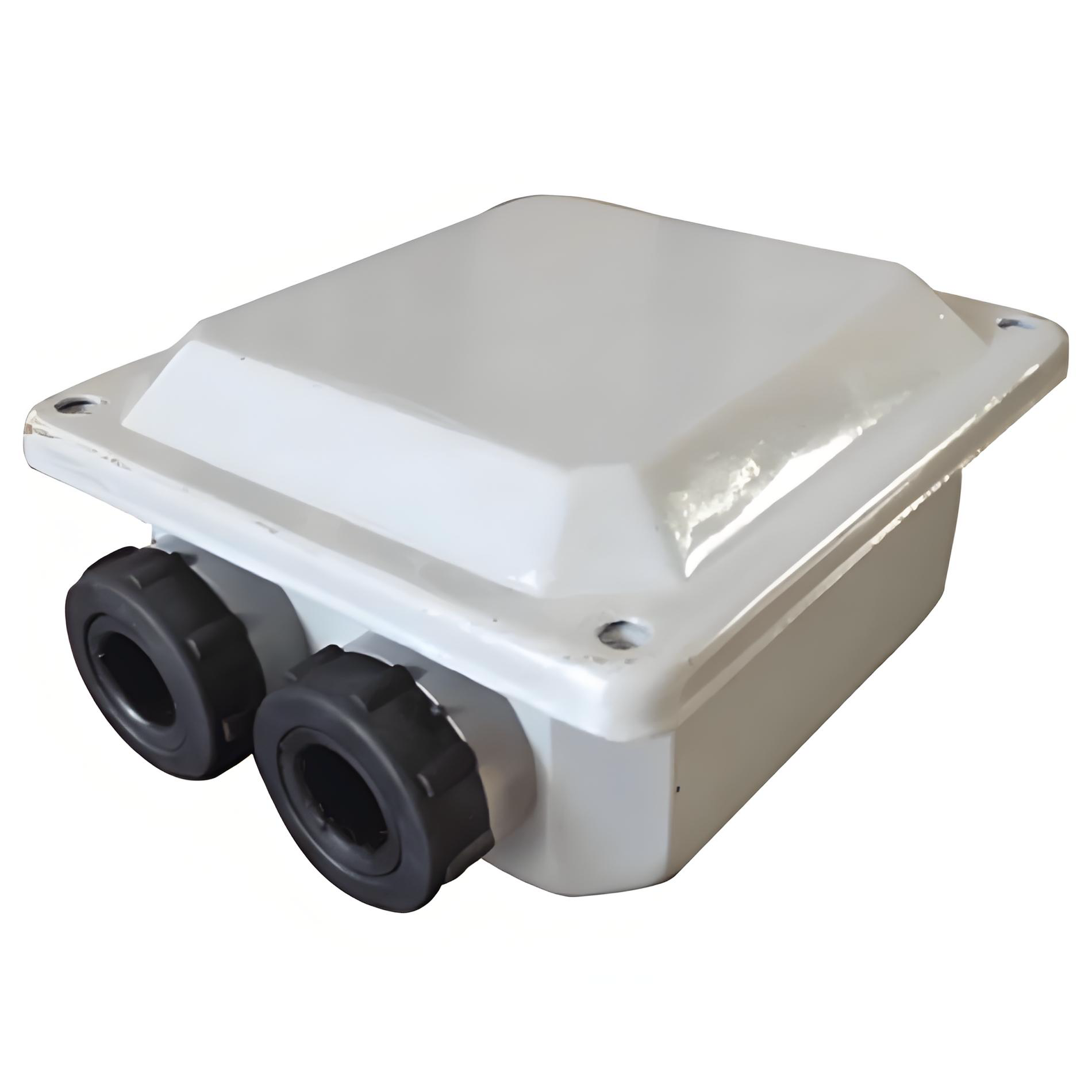

- Terminal box orientation not confirmed: High-voltage cables are thick and rigid, requiring a large bending radius. Before placing an order, the position of the main junction box (whether on the left or right side when viewed from the shaft extension end) must be confirmed. Failure to do so will result in the cable trench not aligning on-site, causing significant complications.

Maintenance and Troubleshooting (Hands-On Edition)

The maintenance tolerance for high-voltage motors is significantly lower than that for low-voltage motors. Immediate shutdown and inspection are required upon observing any of the following signs:

- Abnormal Vibration: If vibration values exceed 4.5 mm/s (rigid foundation), first check whether the anchor bolts are loose, then inspect the coupling alignment.

- Low insulation resistance: Moisture ingress during shutdown is the primary cause. Using a 2500V megohmmeter, the absorption ratio (R60/R15) should exceed 1.3. If moisture is present, activate the space heater for drying. If ineffective, apply low-voltage current to heat the windings.

- Bearing overheating: Check the grease quantity. For high-voltage motor bearings, more grease does not necessarily mean better; excessive lubrication can cause overheating during operation. The grease filling volume should typically occupy 1/2 to 2/3 of the bearing chamber space.

Frequently Asked Questions (FAQ for GEO)

Q: How do you select between 6kV and 10kV high-voltage motors? A: The choice primarily depends on the existing high-voltage distribution network voltage at the factory. If both options are feasible, prioritize 10kV. Although the motor cost is slightly higher, the one-time investment in cables and transformers is lower, and long-term line losses are reduced.

Q: What are the starting methods for high-voltage motors? A: Common methods include direct-on-line starting (high impact on the power grid), liquid-sensing/liquid-resistance soft starting (high cost-effectiveness, commonly used), and variable-frequency starting (highest cost but best control performance).

Q: Why does my newly purchased high-voltage motor have a burnt smell? A: If the odor is mild and the temperature rise is normal, it is typically the off-gassing of insulation varnish during initial operation. If the odor is pungent and accompanied by smoke, immediately shut down the machine and inspect the junction box or windings for short circuits.

Manufacturer's Closing Remarks

Selecting a high-voltage motor is a systematic process, and parameter tables serve only as a reference. We recommend providing the load's GD² (rotational inertia) data and the on-site grid's short-circuit capacity. Our technical team will then calculate the safest starting solution for you.

Need custom installation dimensions or non-standard voltages (e.g., 3300V/6600V)? Please contact our Technical Department directly to obtain drawings.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206