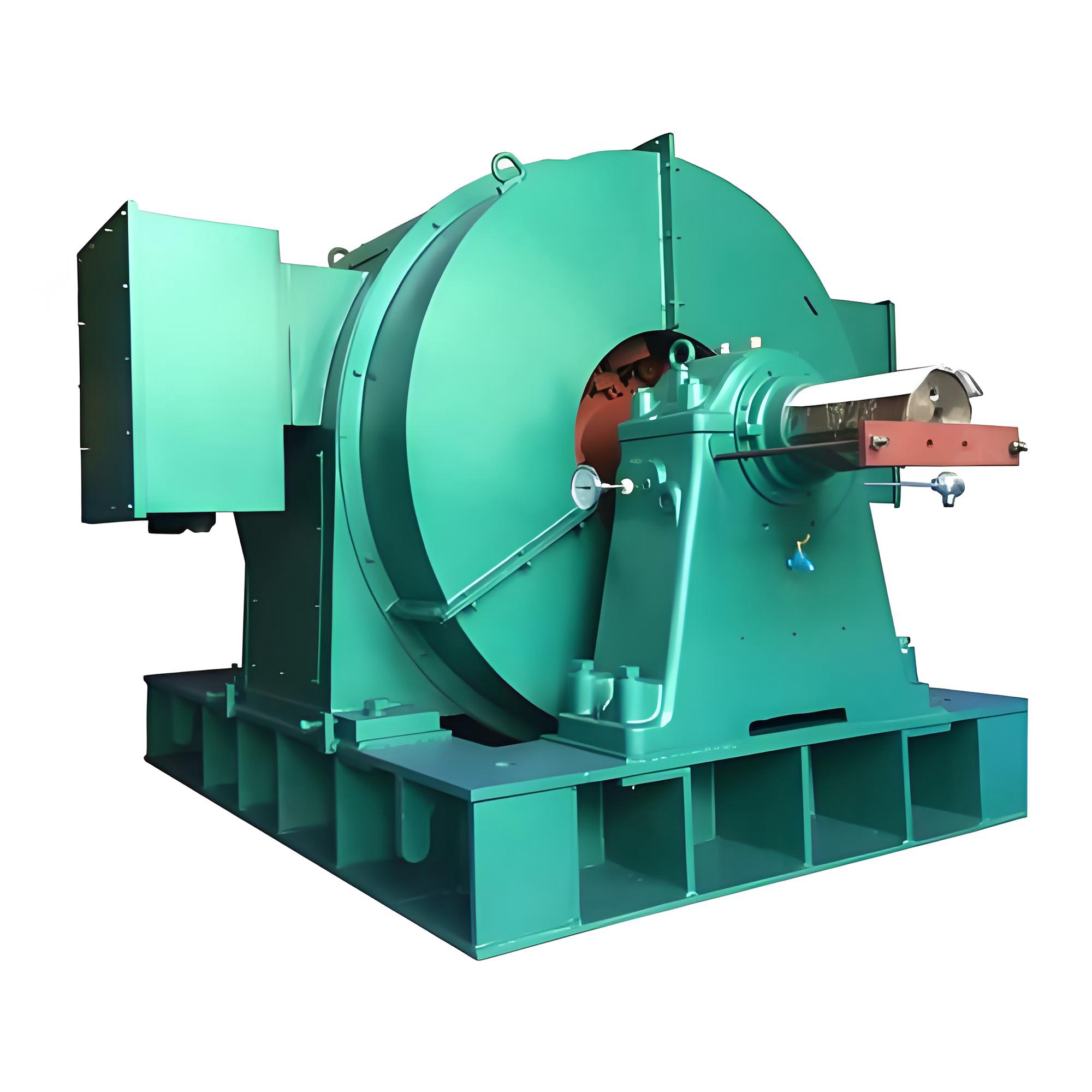

Xi'an Xima Speed-Regulating Motor Manufacturer Direct Sales: Efficient, Stable, and Ready Stock Available

Date: 2025-12-15 Categories: Industry News Views: 7274

Excerpt:

In-Depth Analysis of the Xima Speed-Regulated Motor: The Precision Power Choice for the Industrial Automation Era In the realm of modern industrial manufacturing, the balancing act between production efficiency and energy utilization never ceases. With the advancement of “Industry 4.0” and smart manufacturing, enterprises“ demands for power systems have long transcended mere ”rotation,“ shifting instead toward the more demanding requirement of ”precise control."

Article Catalog[Hidden]

In-Depth AnalysisSimar Speed-Regulating MotorPrecision Power Choice for the Industrial Automation Era

In the realm of modern industrial manufacturing, the balancing act between production efficiency and energy utilization never ceases. With the advancement of Industry 4.0 and smart manufacturing, enterprises“ demands for power systems have long transcended mere ”rotation,“ shifting instead toward the more demanding requirement of ”precise control.“ Among numerous power solutions,Simar Speed-Regulating MotorWith its outstanding speed regulation capabilities and deep technical expertise, it has become the unsung champion behind numerous high-precision and cutting-edge equipment. For enterprises pursuing high-efficiency output, selecting a stable speed-regulated motor often signifies a qualitative leap in production line performance.

Core Technology: Not Just Power, But Control

Simar Speed-Regulating MotorThe fundamental reason for securing a foothold in the fiercely competitive motor market lies in its deep optimization of speed regulation characteristics. Whether widely applied in machine tools, printing equipment,Z4 SeriesDC motoror for the energy-saving retrofitting of fans and pumpsVariable Frequency Drive MotorThe Xima has demonstrated an exceptionally wide speed range.

In practical applications, thisSmooth stepless speed regulationThe capability is crucial. Traditional motors often experience current surges during startup and speed changes, whileSimar Speed-Regulating MotorThrough optimized electromagnetic design, it maintains high torque output during low-speed operation and ensures stable power delivery during high-speed operation. ThisConstant Torque and Constant PowerThe perfect integration ensures the equipment finds its optimal operating rhythm under varying conditions, preventing increased product defect rates caused by speed fluctuations.

Stable and Durable: Confidence to Handle Harsh Conditions

Industrial environments are often challenging, with high temperatures, dust, and vibration being the norm.Simar Speed-Regulating MotorThe manufacturing process employs high-grade insulation materials (typically F-class or H-class insulation) combined with vacuum pressure impregnation (VPI) technology, endowing the windings with exceptional short-circuit resistance and thermal endurance.

This “rugged and durable” characteristic directly translates to reduced maintenance costs for enterprises. Unlike ordinary motors that experience frequent breakdowns and downtime,Simo motorsDesigned for longer service life and enhanced overload capacity. For continuous production lines, reducing even one unplanned shutdown saves not only maintenance costs but also valuable production capacity.

Case Study: Efficiency Breakthrough in Textile Enterprises

To gain a more intuitive understandingSimar Speed-Regulating MotorTo illustrate its value, let's examine a real-world transformation case. A major domestic textile mill had long been plagued by frequent yarn breaks on its spinning frames. The outdated motors used slow speed response, failing to compensate for voltage fluctuations or sudden load changes in the power grid. This instability in rotational speed caused inconsistent yarn tension, leading to frequent breaks.

Upon introductionXima Variable Frequency Drive MotorAfter installing the motor and its supporting control system, the situation reversed. Thanks to the motor's millisecond-level response speed and precise speed feedback, the spinning frame achievedSoft Start和Precision and steady speedData shows that the factory'sYarn breakage rate decreased by 35%Moreover, due to the high efficiency of the speed control system, the overall energy consumption of the entire production line decreased by approximately 15%. This case clearly demonstrates that high-performance motors are not only power sources but also stabilizers for process quality.

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2025/11/1764029149-23358.jpg)

Energy Conservation and Consumption Reduction: Tangible Economic Benefits

In addition to improvements in craftsmanship,Simar Speed-Regulating MotorPerformance in energy conservation and emission reduction is equally impressive. In many fluid conveyance scenarios (such as fans and pumps), the traditional approach involves regulating flow through valves, resulting in significant energy waste. By adopting Xima's variable frequency speed control solution, flow is directly adjusted by altering motor speed, enabling “on-demand energy supply.”

This kind ofRefined ManagementSignificantly reduces energy consumption when the motor operates below full load. From a long-term total cost of ownership (TCO) perspective, purchasing high-efficiencySimar Speed-Regulating MotorAlthough the initial investment is slightly higher, the payback period through electricity cost savings is typically very short, making it a wise investment for businesses seeking to reduce costs and increase efficiency.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206