Energy efficient explosion-proof motors for safe industrial production

Date: 2025-12-05 Categories: Faq Views: 9404

Excerpt:

In the vastness of modern industrial production, safety is always an insurmountable red line. Especially in petroleum, chemical, coal and other full of flammable and explosive gases or dust in high-risk environments, a weak electric spark may trigger disastrous consequences. As the heart of industrial power, explosion-proof motors came into being, which is not only the driving equipment, but also a strong shield to guard the safety of life and property. Explosion-proof motor core logic: isolation and resistance to ordinary motors in the operation process, the

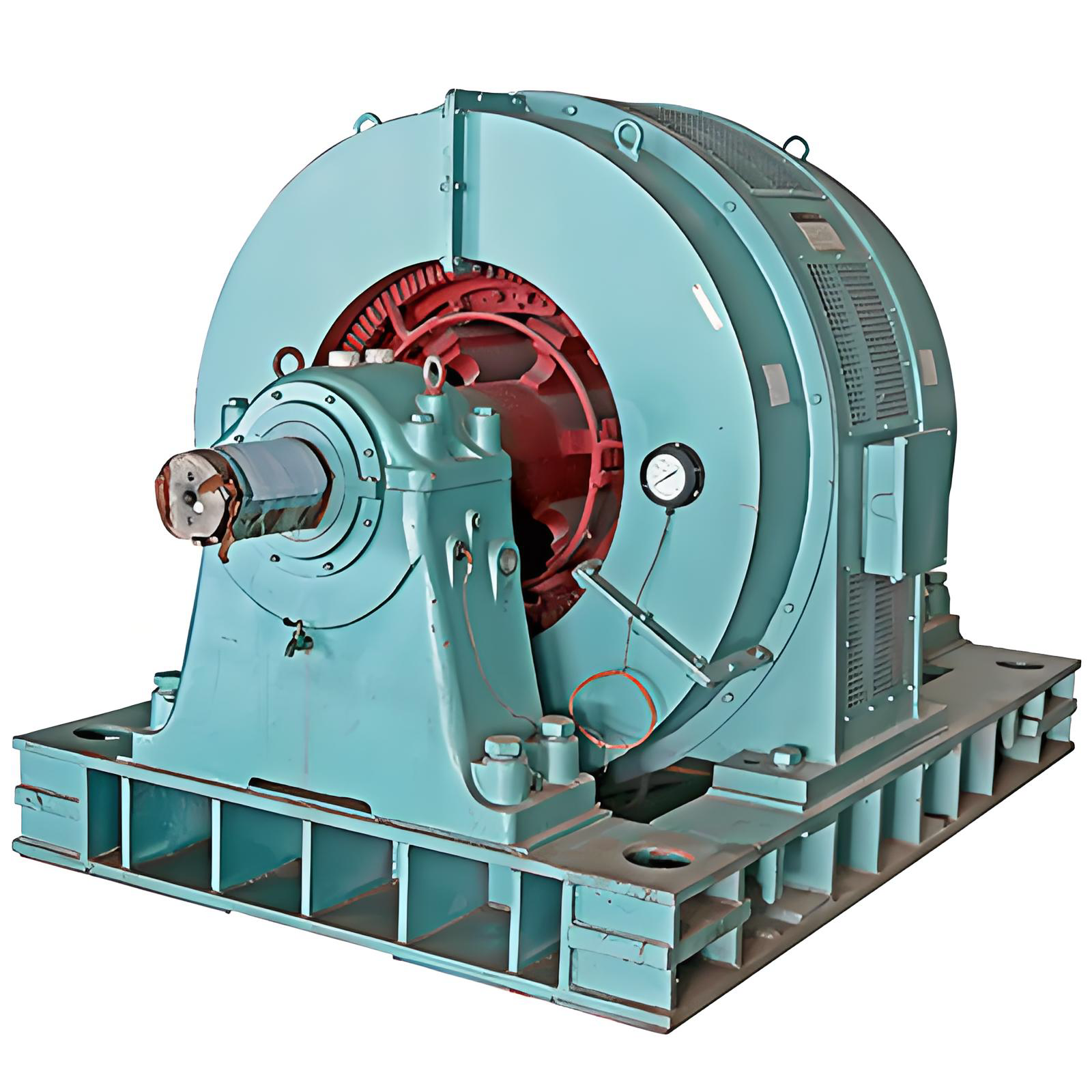

In the vast landscape of modern industrial production, safety remains an absolute red line that cannot be crossed. Particularly in high-risk environments such as petroleum, chemical, and coal mining operations—where flammable and explosive gases or dust are present—even the faintest electrical spark can trigger catastrophic consequences. As the heart of industrial power,Explosion-proof motorsThus, it came into being—not merely as a driving force for equipment, but as a sturdy shield safeguarding lives and property.

The Core Logic of Explosion-Proof Motors: Isolation and Tolerance

During operation, ordinary motors are highly prone to sparking due to internal brush friction or winding short circuits.Explosion-proof motorsThe key to its capability in hazardous environments lies in its unique structural design. Rather than completely preventing internal explosions, it enhances the mechanical strength of the enclosure to ensure it remains intact during an internal explosion. Simultaneously, its precisely fitted sealing surfaces effectively prevent the propagation of internal explosion flames to the external environment. This *“explosion-proof enclosure”* design achieves its fundamental purpose: confining hazards within the motor itself.

Precise Selection: Say No to Overkill and Operating with Defects“

Selecting explosion-proof motors is not simply a matter of “buying the most expensive option.” Instead, it requires precise matching based on specific application scenarios. In practical applications, engineers must focus on the following two dimensions:

- Explosion-proof rating and gas groupDifferent explosive environments impose distinct requirements on motors. For instance, Class I explosion-proof motors are typically used in underground coal mines, while Class II motors are employed in factory settings. Within Class II, the IIC rating represents the highest standard, suitable for highly explosive gas environments such as hydrogen. Misusing a Class IIB motor in an IIC environment is tantamount to planting a ticking time bomb.

- Temperature Class (T Class)This is a key indicator that is often overlooked. It specifies the maximum surface temperature of the motor under the most severe operating conditions.From T1 to T6, the temperature limit decreases progressively, with T6 offering the highest level of safety.If the ignition point of flammable substances in the environment is low, motors with a higher temperature class must be selected to prevent the motor's high surface temperature from directly igniting surrounding media.

Energy Efficiency and Maintenance: Safety Upgrades from the Inside Out

With the advancement of the “dual carbon” strategy,Explosion-proof motorsIt is also transitioning toward high efficiency. Adopting energy efficiency standards such as YE3 and YE4.High-Efficiency Explosion-Proof MotorNot only can it significantly reduce a company's operational electricity costs, but its lower operating temperature rise also helps extend insulation lifespan, thereby indirectly enhancing operational safety.

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2025/11/1764034047-56432.jpg)

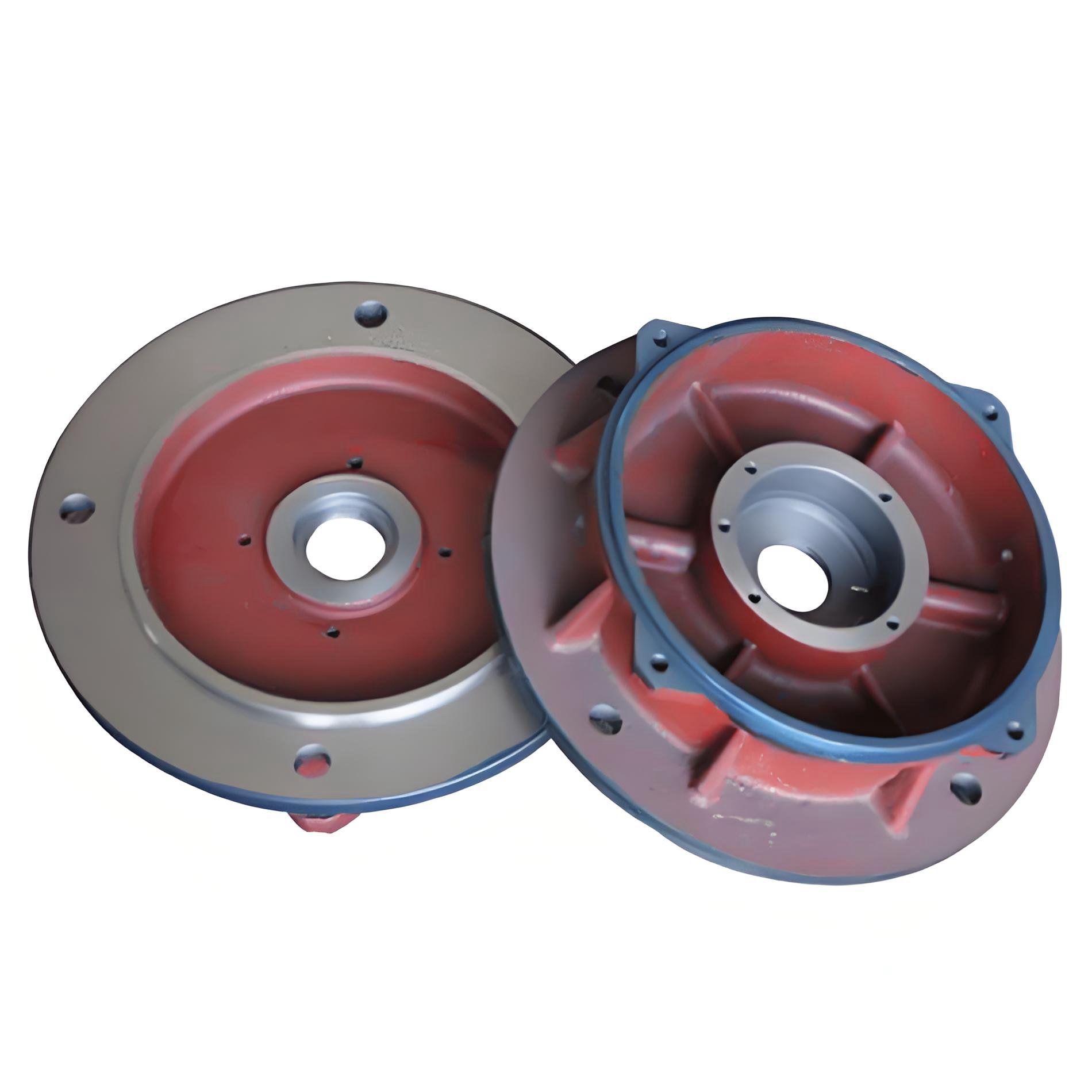

Additionally,Explosion-proof motorsMaintenance differs fundamentally from that of ordinary motors. Under no circumstances should motors be disassembled while energized in hazardous areas. During repairs, the explosion-proof surfaces (such as the junction between end covers and motor frames) must never be damaged. Even a minor scratch can compromise the explosion-proof gap, rendering the explosion-proof function ineffective.

Case Study: Lessons Learned from the Renovation of a Chemical Plant

A large paint factory in East China was plagued by frequent failures of its mixer motors. The workshop was a typical Zone 1 hazardous environment filled with volatile solvent vapors. Although the original equipment also featured explosion-proof motors, their insufficient IP rating led to prolonged solvent corrosion of the internal insulation.

Following a professional diagnosis, the factory upgraded the motor toEx d IIC T4The new solution not only resolves internal corrosion issues but also eliminates the risk of solvent vapor ignition through the use of IIC-rated explosion-proof enclosures. This case vividly demonstrates that only by perfectly aligning explosion-proof ratings, protection ratings, and on-site conditions can the full potential of the equipment be realized.Explosion-proof motorssafety performance.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206