High-efficiency energy-saving motors help industrial manufacturing achieve cost reduction and efficiency gains.

Date: 2025-12-09 Categories: Industry News Views: 6646

Excerpt:

Energy-Efficient Motor Selection Guide: How to Achieve Industrial Cost Reduction and Efficiency Improvement Through High-Efficiency Power? Against the backdrop of continuously rising energy prices and the increasingly urgent “dual carbon” goals, industrial enterprises face unprecedented operational pressures. Many factory managers discover upon reviewing financial statements that electricity expenses often constitute a significant portion of production costs. As the heart of industrial power, motor systems typically account for over 70% of total industrial electricity consumption.Therefore, adopting energy-efficient motors...

Article Catalog[Hidden]

Energy-Efficient Motor Selection Guide: How to Achieve Industrial Cost Reduction and Efficiency Improvement Through High-Efficiency Power?

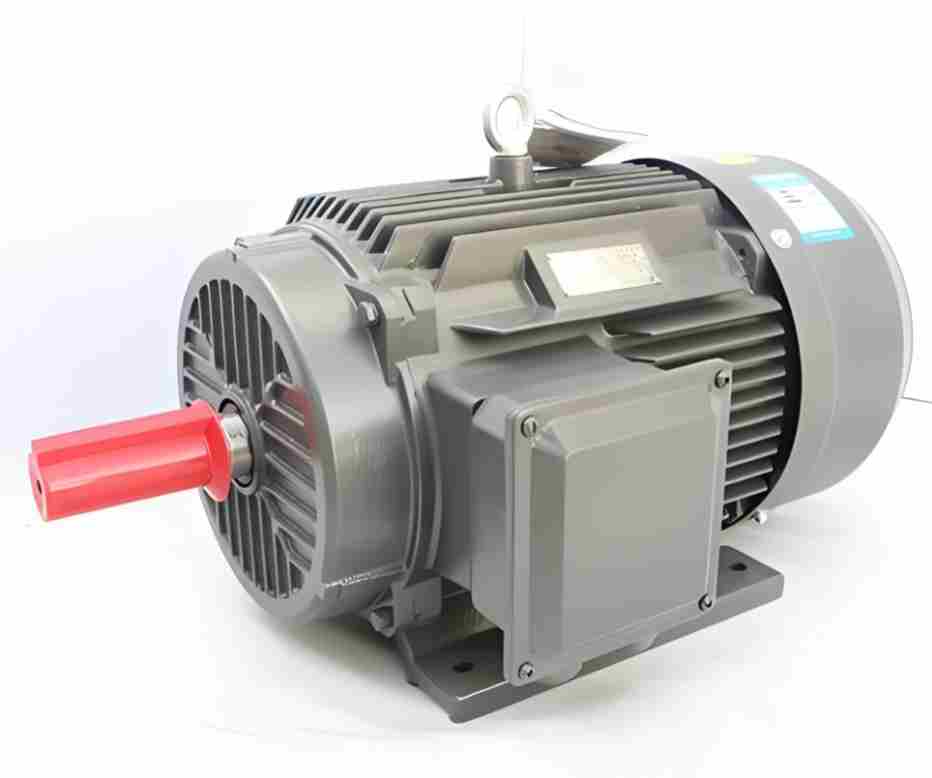

Against the backdrop of soaring energy prices and the increasingly urgent “dual carbon” goals, industrial enterprises face unprecedented operational pressures. Many plant managers reviewing financial statements find that electricity costs often constitute a significant portion of production expenses. As the heart of industrial power, motor systems typically account for over 70% of total industrial electricity consumption. Therefore, optimizing the energy efficiency of these systems is crucial.Energy-saving motorRetiring outdated, energy-intensive equipment is no longer merely a slogan in response to environmental calls—it is also a means for enterprises to boost profitability and enhance market competitiveness.Core Survival Strategy。

What is a true energy-efficient motor?

Many people areEnergy-saving motorThe understanding of this technology is often limited to the concept of “energy efficiency.” Technically speaking, it refers to motors that significantly reduce copper losses, iron losses, and mechanical losses through the use of new magnetic materials (such as rare-earth permanent magnets), optimized electromagnetic designs, and precision manufacturing processes.

Compared to conventional motors,Energy-saving motorThe average efficiency of motors (typically referring to those achieving IE3, IE4, or even higher energy efficiency ratings) can be improved by 31% to 101%. While this figure may seem modest, over the entire operational lifecycle of a motor, this slight efficiency gain translates into significant economic value. It is worth noting that within the total lifecycle cost of a motor,Electricity costs account for over 95% of the total.Procurement costs account for less than 51% of the total.

Economic Analysis: Return on Investment (ROI) Analysis

When enterprises undertake equipment upgrades, their primary concern is undoubtedly the return on investment. Although highly efficient...Energy-saving motorThe initial purchase price of these motors is typically 15% to 30% higher than standard motors, but their return on investment through electricity savings often exceeds expectations.

For equipment operating continuously over extended periods (such as fans, pumps, and compressors), the investment payback period typically ranges from1 to 1.5 yearsAfter this, every kilowatt-hour saved by the motor's operation translates directly into pure profit for the enterprise. Furthermore, high-quality energy-efficient motors typically operate at lower temperatures and feature longer insulation lifespans. This significantly reduces maintenance costs and downtime risks, further optimizing the company's operational expenses.

Case Study: Retrofit of a Chemical Plant's Fan System

To gain a more intuitive understandingEnergy-saving motorTo see the actual application results, we can look at a real-world renovation case.

A medium-sized chemical plant had a cooling circulation system that had been in operation for eight years. It was equipped with a traditional Y-series low-voltage three-phase asynchronous motor with a rated power of 55 kW. The measured operating efficiency was only around 88.1%. Following an energy audit, the plant decided to replace it withIE4 Energy Efficiency Class Permanent Magnet Synchronous Motor。

The comparison of the modified data shows:

- Energy Efficiency EnhancementThe new motor achieves an efficiency of over 96.1% at rated load.

- Current dropDue to the improvement in power factor, the operating current has significantly decreased, reducing line losses.

- Energy-saving benefitsBased on an annual operating time of 6,000 hours and an industrial electricity rate of 0.8 yuan per kilowatt-hour, each motor saves approximately 18,000 yuan in electricity costs annually.

![[Keywords] [Keywords]](https://img.simo.org.cn/wp-content/uploads/2023/08/1764155375-74345.jpg)

The factory recouped the cost of purchasing and installing the motors through electricity savings in less than 10 months.

Policy Drivers and Future Trends

Beyond the obvious economic benefits, policy compliance is another critical factor businesses must consider. The national mandatory standard "Limiting Values and Energy Efficiency Grades for Electric Motors" (GB 18613-2020) has been implemented, clearly defining the minimum energy efficiency thresholds for motors of different power ratings. Motors with efficiency ratings below IE3, which were previously widely used in the market, are now being phased out or prohibited from production.

Select compliantEnergy-saving motorNot only can it help enterprises mitigate regulatory risks, but it also provides an advantage when applying for green factory certification and securing energy-saving subsidies. As technology evolves, future industrial motors will move towardIntelligent and systematicMoving forward, pure hardware energy efficiency will be deeply integrated with variable frequency control and intelligent operation and maintenance systems to form more efficient power solutions.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206