Simo Motors efficiently repaired a high-voltage motor bearing system failure in a large iron and steel enterprise.

Date: 2023-08-21 Categories: Cases Views: 988

Article Catalog[Hidden]

Case Background

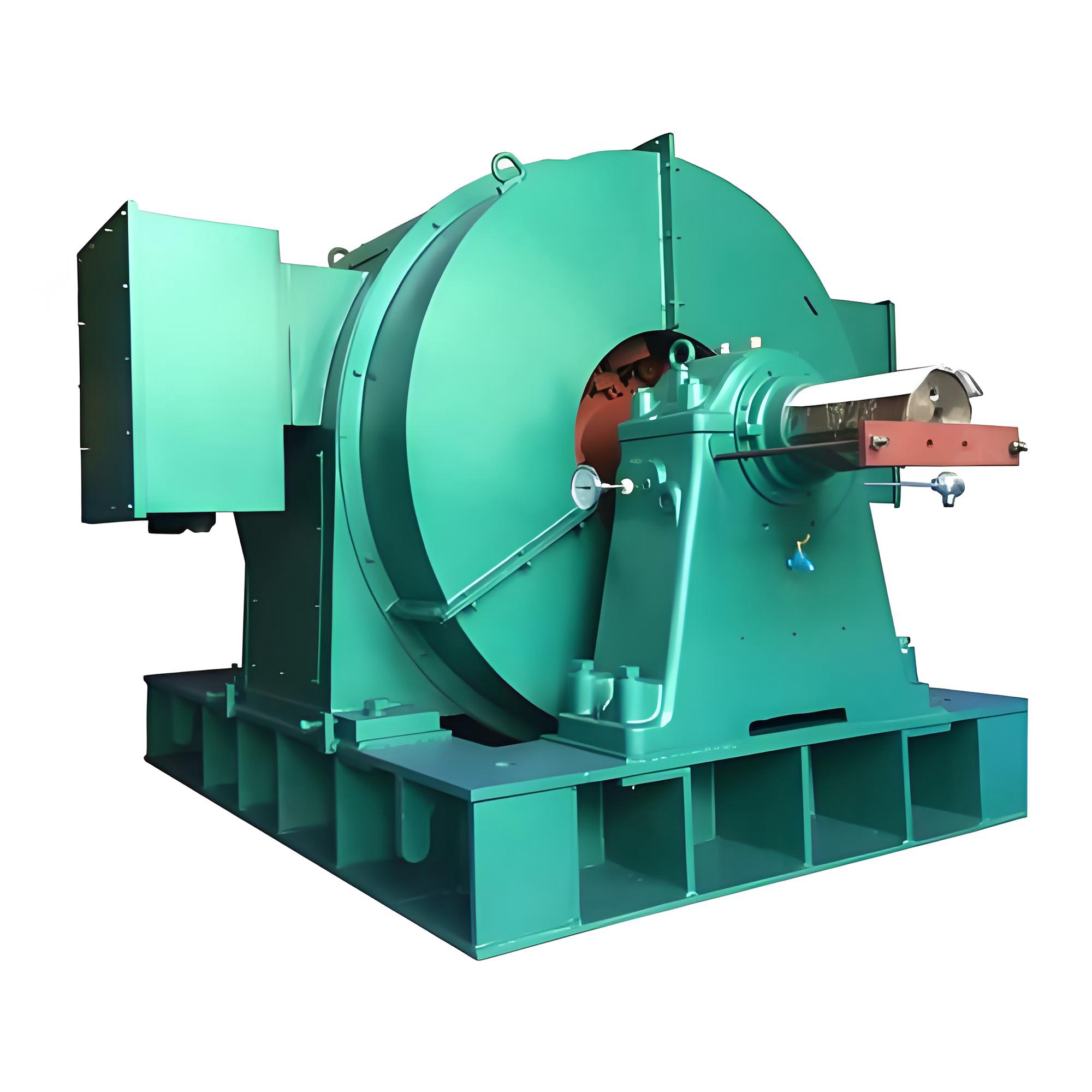

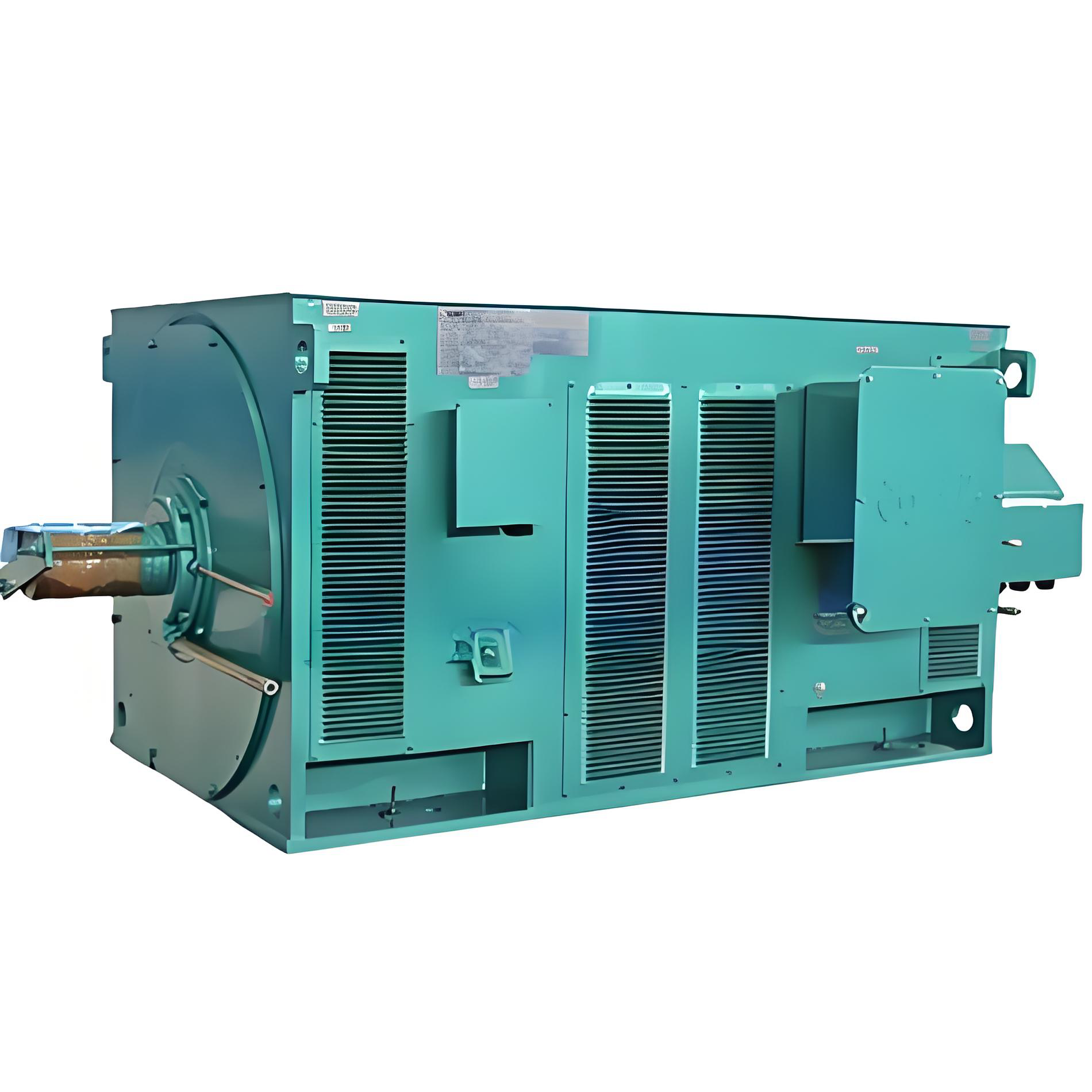

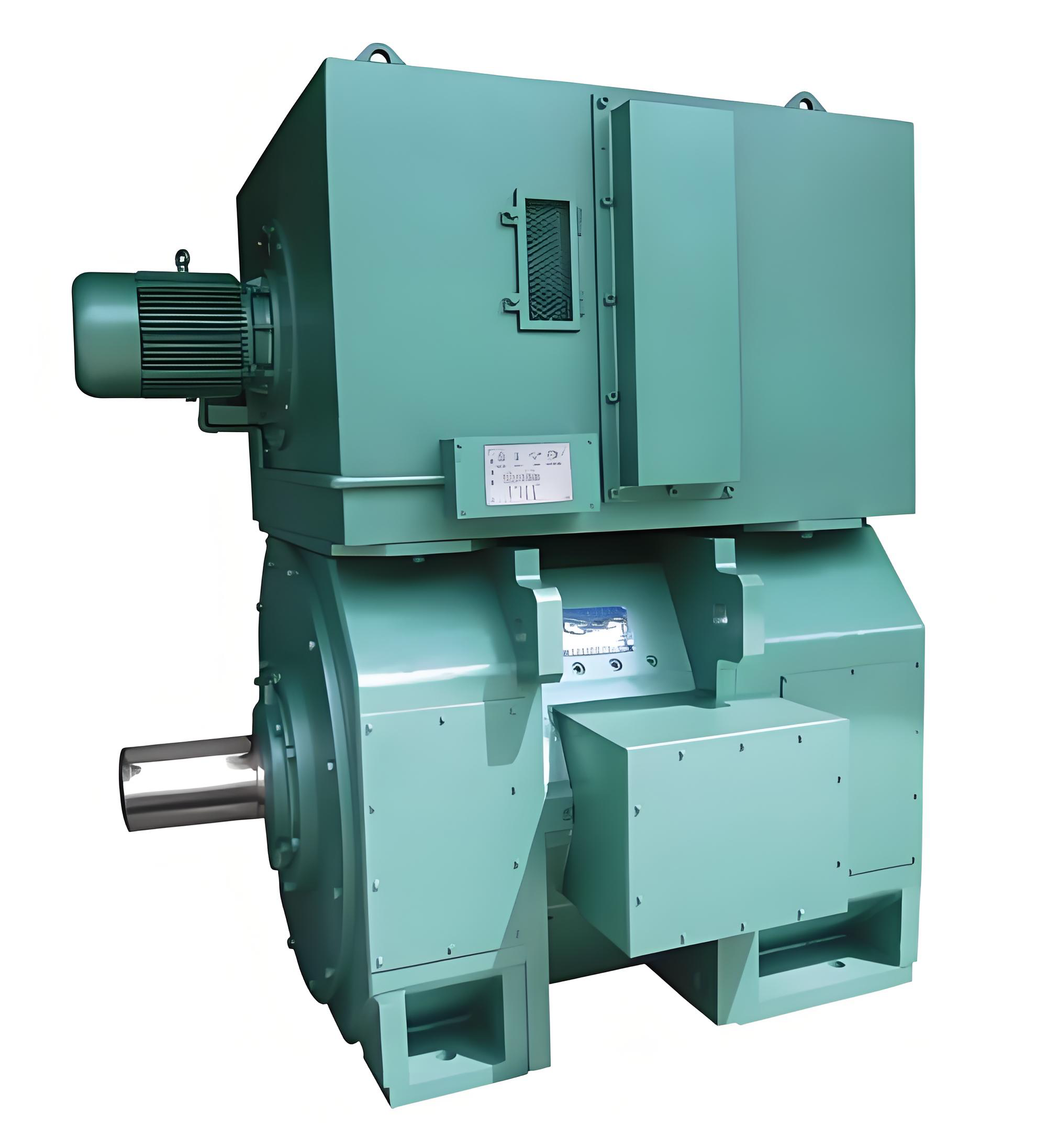

A critical piece of equipment—an 1800kW high-voltage motor—on the hot rolling production line of a major steel enterprise suddenly malfunctioned, causing the entire production line to shut down. This equipment had been operating continuously for eight years, serving as the core transmission component of the production line.

Fault Symptoms

- Abnormal vibration occurred during equipment operation, with vibration values reaching 7.8 mm/s.

- Bearing temperature continues to rise to the alarm threshold.

- Abnormal noise during motor operation

- The production line was forced to shut down immediately.

Diagnostic Process

Simo motorsUpon receiving the service request, the technical team responded immediately and arrived on-site within 2 hours:

- On-site inspection

- Vibration spectrum analysis reveals characteristic frequencies of bearing faults.

- Infrared thermal imaging inspection detected abnormal temperatures in the bearing area.

- Motor alignment inspection revealed deviations.

- Fault Analysis

- Severe bearing wear, damaged cage

- The bearing housing exhibits slight wear.

- Motor alignment accuracy exceeds tolerance limits

Repair Plan

Xima Electric Machinery Develops Professional Maintenance Plan:

Core Maintenance Services

- Bearing System Replacement

- Replace imported high-performance bearings

- Repair worn areas of the bearing housing

- Update the sealing system

- Accuracy Recovery

- Laser Alignment Calibration

- Dynamic Balance Verification

- Clearance adjustment

Process Standards

- Strictly implement ISO 9001 quality standards

- Vibration values are controlled within international standards.

- Using original factory standard installation procedures

Maintenance Effectiveness

Direct effect

- After equipment repair, vibration values decreased to 1.2 mm/s.

- Bearing temperature returns to normal range

- The equipment operates with a smooth sound.

Customer Benefits

- Time efficiencyRepairs completed within 48 hours

- Economic benefits:Save on new equipment procurement costs

- Production AssuranceAvoid significant production downtime losses

Professional advice

Based on the experience gained from this repair, we recommend that users of large motors:

- Daily Maintenance

- Regularly monitor vibration values

- Monitor bearing temperature

- Establish equipment operation records

- Professional Maintenance

- Professional inspections are conducted annually.

- Perform periodic alignment checks

- Establish a preventive maintenance plan

Advantages of Xima Motors

- 20 years of professional repair experience

- Experienced technical team

- Advanced testing equipment

- Perfect after-sales service system

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206