Simo motors successfully solved the insulation breakdown fault of 6kV high-voltage motors.

Date: 2023-08-21 Categories: Cases Views: 988

Article Catalog[Hidden]

I. Fault Background: Sudden shutdown, critical production situation

Device Information:

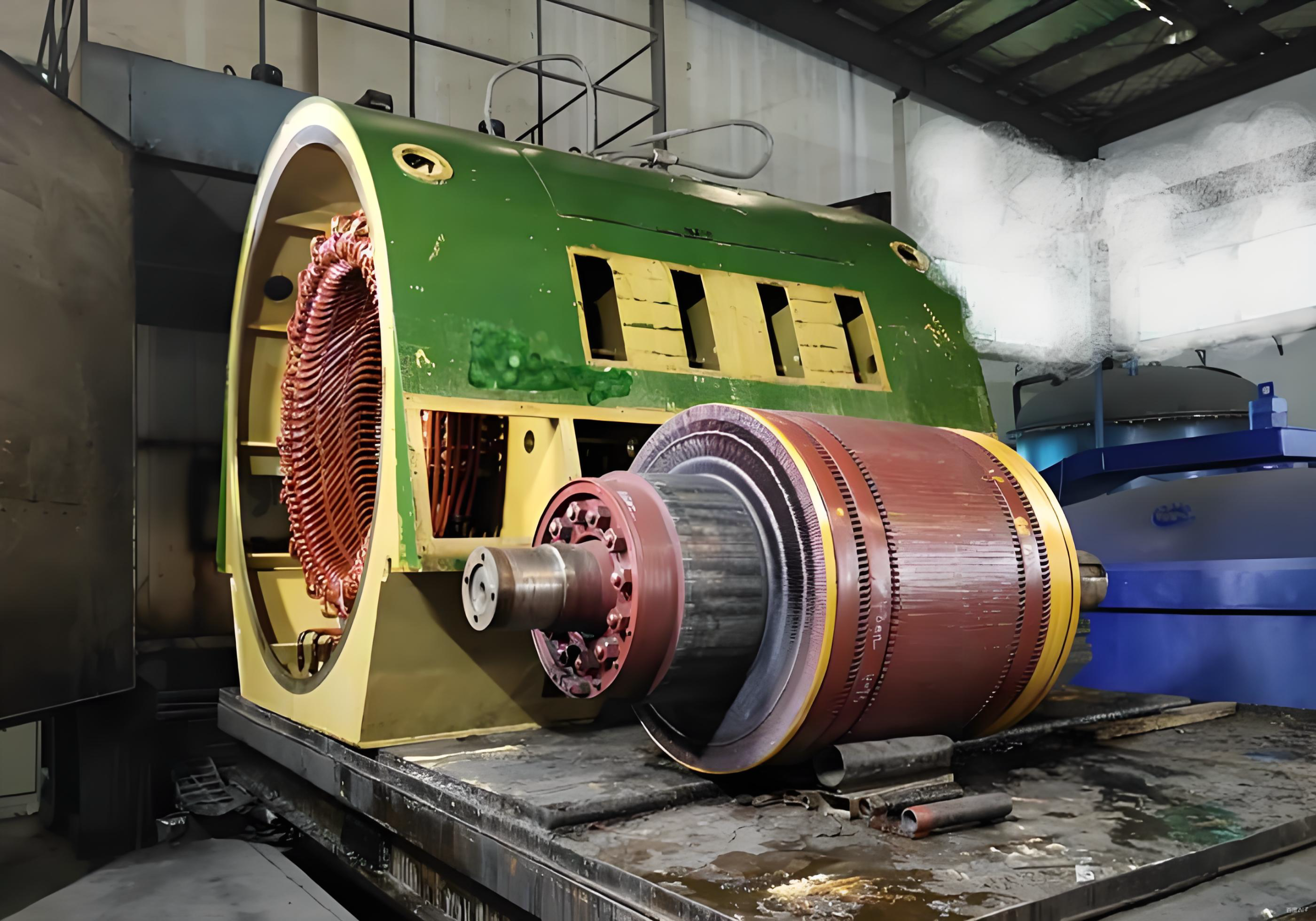

- Customer Equipment: Drive motor for a large mining crusher

- Motor Model: YR560-4 High-Voltage Asynchronous Motor

- Key Parameters: rating780 kWRated Voltage6kV

- Fault Symptom: During operation, the motorInsulation breakdown causing sudden shutdownand caused the system to tripDuring the on-site inspection, it was found that the motorMultiple insulation failures exist in the stator windings.This has severely impacted production progress.

II. In-Depth Diagnosis: Identifying the Root Cause of Insulation Breakdown

Simo motorsUpon receiving the service request, the maintenance team promptly arrived on-site and conducted a systematic diagnostic assessment:

- Electrical Performance Testing:

- Using a megohmmeter to measure the insulation resistance between the windings and ground, the resistance value was found to beBelow 0.5 megohmsFor old motors, the winding-to-ground resistance should exceed 0.5 megohms; for new motors, it should exceed 5 megohms.), confirming that the insulation has severely deteriorated.

- DC resistance testing indicates balanced resistance values across all three phases, ruling out winding open circuits and short circuits.

- Internal winding inspection:

- Root Cause Analysis:

- Insulation Aging and Degradation: The motor operates continuously in harsh environments, causing the winding insulation to deteriorate due to moisture ingress, aging, and electrical stress.。

- External factors: It cannot be ruled out that the winding may have suffered partial insulation damage due to overvoltage surges during operation or external forces during on-site maintenance.。

III. Specialized maintenance programme and implementation process

Based on the diagnostic findings, we developed and implemented a comprehensive repair plan centered onRepair of Damaged Windings and Restoration of the Insulation System。

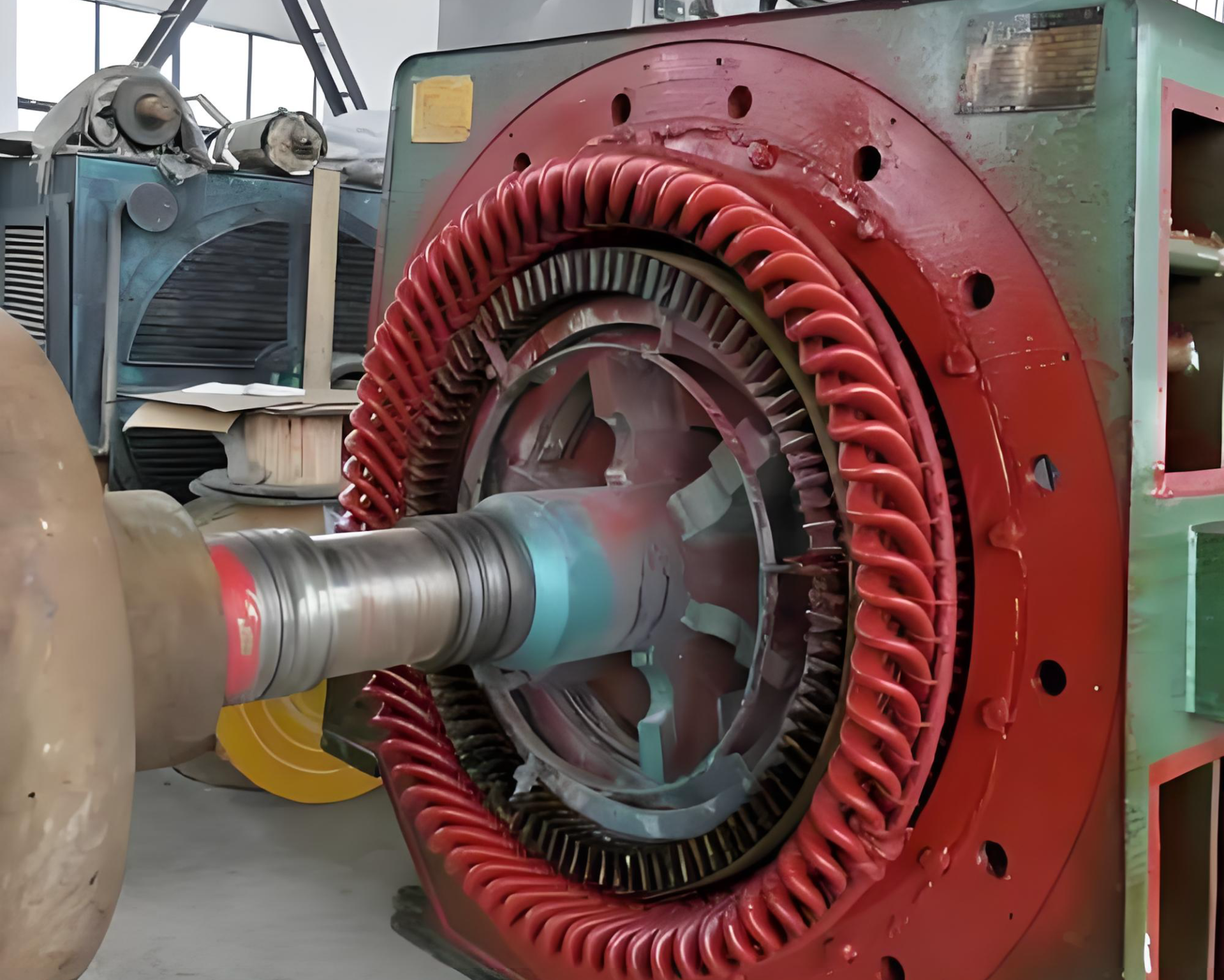

1. Localized Repair and Insulation Treatment of Windings

- Cutting treatment: Mark the breakdown points on each coil with a red pen, then scrape away the insulation at these points. If there are visible black breakdown spots on the wire, scrape them off to expose the copper wire, preserving as much of the wire's original glass fiber insulation as possible. At the breakdown points, trim the coil's insulation to ground into a sloped surface, cutting the outermost layer for 80 to 100 millimeters.

- Moisture-proofing and Painting: Use a hair dryer to blow-dry the insulation around the coil's cut points, expelling any moisture. Once cooled, apply epoxy paint mixed to a specific volume ratio (hardener: epoxy resin: toluene = 6:4:1.5).。

- Wrapping mica tape: 用Pink Mica TapeWrap the cut area tightly, minimizing gaps (air pockets trapped within the insulation layer will reduce the motor's withstand voltage rating). Start wrapping from the center and work outward toward both sides. The wrapped thickness should exceed the original insulation by 5–6 mm. After wrapping, apply a coat of epoxy paint.。

2. Heating, shaping, and curing

- Place the coil wrapped with pink mica tape into a homemade iron mold for heating and shaping. The effective area of the iron mold matches the standard coil dimensions, with a length of 100–120 mm. Line the mold cavity with a sheet of resin film. Secure the upper and lower molds with screws, then heat on a 50-watt electric stove for 2–2.5 hours before allowing to cool naturally.

- After insulating the slanted edges of the coil (winding ends), cure them by exposing them to a 500-watt iodine tungsten lamp for 2 to 0.5 hours.。

3. Overall Inspection and Verification

After the repair was completed, multi-level testing and validation were conducted:

- Insulation resistance test: After repair, the insulation resistance between the windings and ground, as well as between phases, was measured and restored to5 MΩ or higher(New Motor Standards)), confirming that the insulation system has been fully restored.

- Withstand Voltage Test: Perform a withstand voltage test on the finished coils; only those that pass may be released from production.。

- Trial run: The motor operated smoothly during no-load testing, with all parameters—including vibration, temperature rise, and current—within normal ranges.

IV. Maintenance results and customer value

- The fault is completely eradicated: After repair, the motor has been operating continuously and stably for over8 monthsNo further insulation faults have occurred.

- Restore efficient production: The customer's critical crushing production line was swiftly restored, preventing significant economic losses that would have resulted from prolonged equipment downtime.

- Earn long-term trust: This successful maintenance service earned high praise from the client, who subsequently signed a contract for all futureHigh voltage motorsMaintenance Agreement.

V. Case summary and inspiration

1. Core message

- Accurate diagnosis is the prerequisite: High-voltage motor insulation faults requireConduct an in-depth analysis of the root cause of the failureCombining electrical testing with internal inspection to precisely pinpoint the cause of insulation degradation.

- Standardized maintenance is the guarantee: Winding Insulation RepairEvery step, from cutting and wrapping to heating and curing, must adhere to strict process standards.Details determine success or failure, and this is also the key to the quality of Xima Motor repairs.

- Emergency and Long-Term Considerations: Partial Repair Method for CoilsEmergency Repaircan bring back from the deadHowever, from the perspective of long-term normal use, non-damaging coils should still be prioritized for wire embedding.。

2. Management Recommendations for High-Voltage Motor Users

- Establish a regular insulation monitoring system: Regularly measure and record the motor'sWinding Insulation Resistancetimely detection of insulation degradation trends。

- Prioritize operating environment and maintenance: Improve the operating environment of electric motors by minimizing adverse factors such as humidity and dust. Strictly adhere to procedures for lubricating and maintaining motors, paying particular attention to the selection of lubricating grease and the correct lubrication methods.。

- Watch for warning signs: For issues arising during operationAbnormal heat, abnormal noise, vibrationIn such situations, monitoring should be strengthened and operations should be promptly suspended for maintenance to prevent the accident from escalating.。

(Call to Action CTA)

Is your high-voltage motor also facingInsulation degradation, winding breakdown, or frequent failuresAre you troubled by equipment failures? Do you want reliable maintenance coverage for your critical equipment?

Contact the Simo Motors expert team todayGet a free technical consultation and initial equipment health assessment! We are committed to providing the same professional and rigorous high voltage motor repair, maintenance and full life cycle management services as in this case.

Xi'an Simo Motor -- Your expert for high-voltage motor system solutions

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206