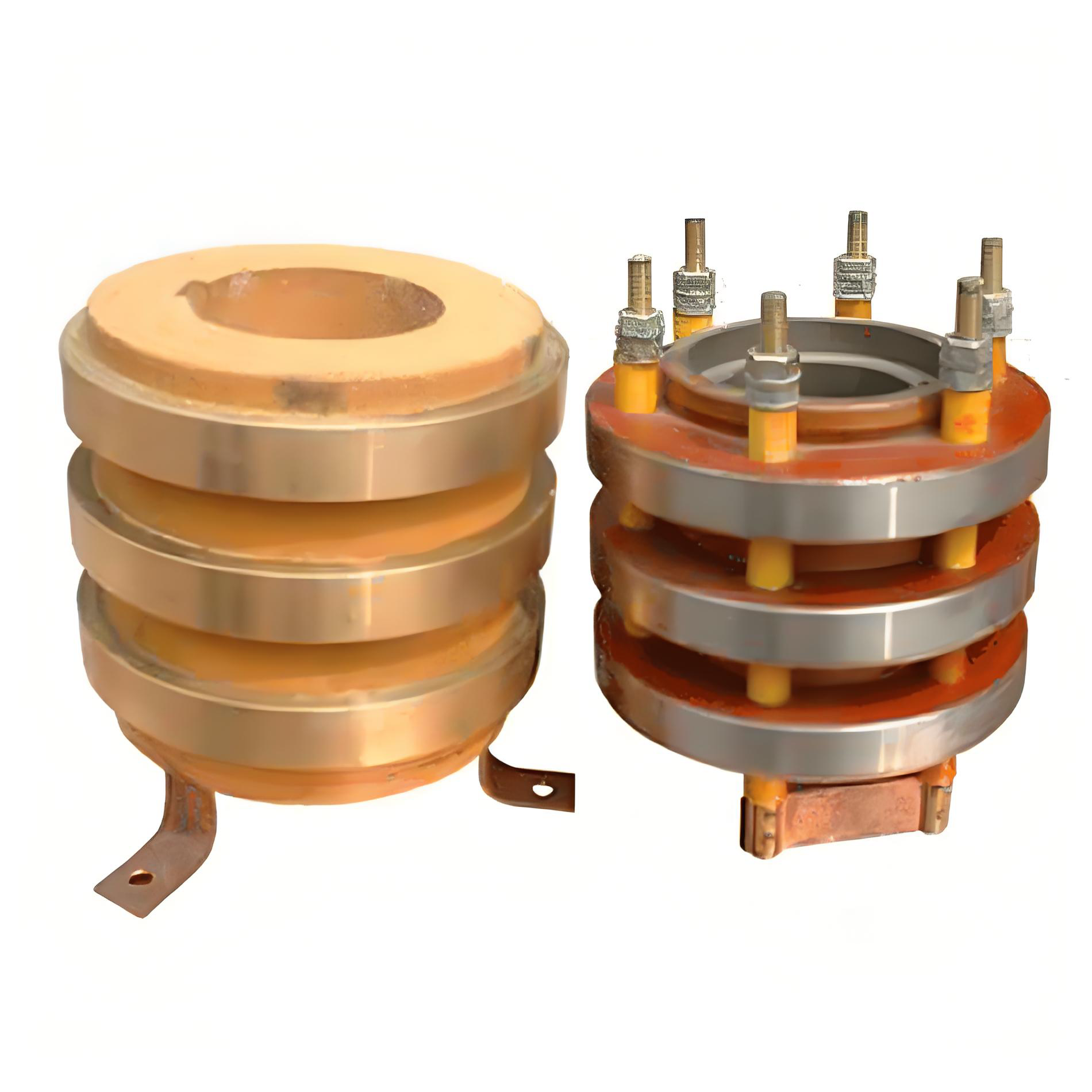

1000kW DC motor commutator ring-fire failure

Date: 2023-08-21 Categories: Cases Views: 1000

Excerpt:

A repair case of a 1000kW large DC motor that was shut down due to a serious ring fire in the commutator. Through precise diagnosis and systematic repair, Simo's maintenance team not only solved the commutator burnout problem, but also restored the stable operation of the equipment for the customer through a comprehensive preventive maintenance program, avoiding major production losses. This case demonstrates the professional strength of Simo Motor in the field of large DC motor repair.

Article Catalog[Hidden]

I. Fault Background: Sudden ring fire, production interruption

Device Information:

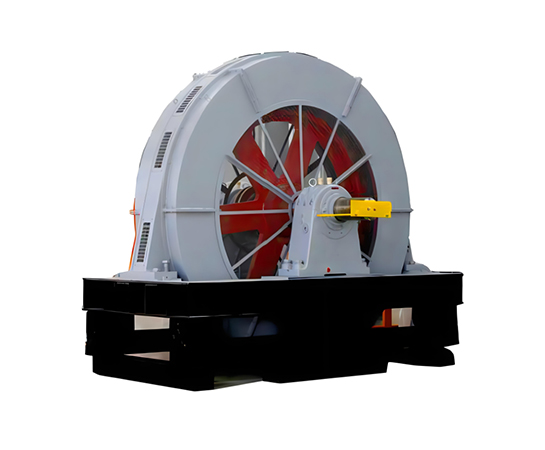

- Customer Equipment: Main rolling mill drive motor at a large steel rolling mill

- Motor Model: Z Series 1000kW DC Motor

- Key Parameters: rating1000 kWArmature voltage660VExcitation voltage220V

- Fault Symptom: The motor is in operation.Severe arcing in the commutatorThe carbon brushes and brush holders melted and fused together, causing the system to trip and halt production.On-site inspections revealed multiplebrush holderDamage, with severe surface erosion on the commutator, significantly impacting production progress.

II. In-Depth Diagnosis: Tracing the Root Cause of Ringing

Simo motorsUpon receiving the service request, the maintenance team promptly arrived on-site and conducted a systematic diagnostic assessment:

1. Site Inspection and Data Collection

- Upon inspecting the surface of the motor commutator, it was found thatEvident arc burn marks。

- Inspecting the condition of the carbon brushes, it was found thatCarbon brushes are severely worn.Partial breakage of the carbon brush copper braid has resulted in poor electrical contact.。

- Measure the motor's insulation resistance to confirm that the insulation performance has not yet completely failed, but has been compromised.。

2. Root Cause Analysis

- Insufficient maintenance: Failure to replace worn carbon brushes in a timely manner resulted in uneven current distribution and localized overheating.。

- Electrical connection defects: Poor contact between the carbon brush and brush holder causes overheating and wire breakage, ultimately resulting in a short-circuit arc.。

- Control System Factors: Similar to othersDC motorFailure may be due to improper control parameter settings, which exacerbated system instability.。

III. Specialized maintenance programme and implementation process

Based on the diagnostic findings, we developed and implemented a comprehensive repair plan:

1. Commutator Repair and Surface Treatment

- Precision Turning: Perform precision turning on the commutator surface to remove the burnt layer, restoring its concentricity and surface finish.

- Groove treatment: Remanufacture the mica slots between commutator segments to ensure consistent slot depth and smooth edges, preventing brush chatter.

- Surface polishing: A specialized polishing process is employed to achieve a surface roughness of Ra 0.4 on the commutator, ensuring optimal contact with the carbon brushes.

2. Comprehensive Overhaul of the Brush Rack System

- Replacement of the brush holder: Replace all worn brush holders, ensuring their distance and angle relative to the commutator surface meet design specifications.

- Carbon Brush Selection: High-quality metal-graphite carbon brushes are selected to enhance current conduction characteristics and reduce contact voltage drop.

- Pressure adjustment: Precisely adjust the spring pressure of each brush holder to ensure uniformity within ±10%.

3. Reinforcement of Insulation Systems

- Thorough cleaning: Thoroughly clean the interior of the motor to remove carbon powder and oil residue.。

- Insulation Treatment: Clean and dry the windings, then apply insulating varnish to restore and enhance overall insulation performance.

- Insulation Test: After repair, the insulation resistance between the windings and ground, as well as between phases, was measured and restored to5 MΩ or higher(New Motor Standards)。

4. Control System Optimization

- Parameter Calibration: Check and optimize the excitation control parameters to ensure the use ofCurrent Control Modeto avoid potential issues associated with voltage control mode。

- Protection Function Verification: Verify that protection functions such as excitation overcurrent and overheating are operational and effective to prevent fault escalation.。

IV. Maintenance results and customer value

- The fault is completely eradicated: After repair, the motor has been operating continuously and stably for over6 monthsNo further ringing or commutation faults have occurred.

- Significantly enhanced performance: The commutator operating temperature is reduced by 25°C, extending the carbon brush service life by three times and significantly reducing routine maintenance workload.

- Restore efficient production: The customer's critical rolling mill production line was swiftly restored, averting substantial economic losses that would have resulted from prolonged equipment downtime.

- Earn long-term trust: This successful repair service earned high recognition from the customer, who subsequently signed a maintenance agreement covering all DC motors.

V. Case summary and inspiration

1. Core message

- Systemic diagnosis is key: Failures in large DC motors are often the result of multiple factors combined, necessitating a comprehensive inspection of the mechanical, electrical, and control systems.。

- Maintenance is fundamental: Regular, professional maintenance can effectively prevent most DC motor failures and stop minor issues from escalating into major incidents.。

- Standardized maintenance is the guarantee: From commutator processing to insulation restoration, every step must adhere to strict process standards to ensure reliable and long-lasting repair quality.

2. Management Recommendations for DC Motor Users

- Establish a regular inspection system: Regularly inspect the condition of the commutator surface, the wear of the carbon brushes, and the spring pressure.。

- Enhance training for maintenance personnel: Enhance maintenance personnel's understanding of DC motor characteristics and master proper maintenance methods.。

- Improve spare parts management: Stock critical wear parts such as carbon brushes and brush holders to ensure prompt replacement in case of failure.。

- Advancing Preventive Maintenance: Combining condition monitoring with scheduled maintenance enables predictive maintenance to prevent issues before they occur.。

(Call to Action CTA)

Is your large DC motor also facingCommutator ring short circuit, insulation degradation, or frequent failuresAre you troubled by equipment failures? Do you want reliable maintenance coverage for your critical equipment?

Contact the Simo Motors expert team todayGet free technical consultation and a preliminary equipment health assessment! We promise to deliver large DC motor repair, maintenance, and full lifecycle management services with the same level of professionalism and rigor as demonstrated in this case.

Xi'an Simo Motor —— Your go-to expert for large DC motor system solutions

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206