Article Catalog[Hidden]

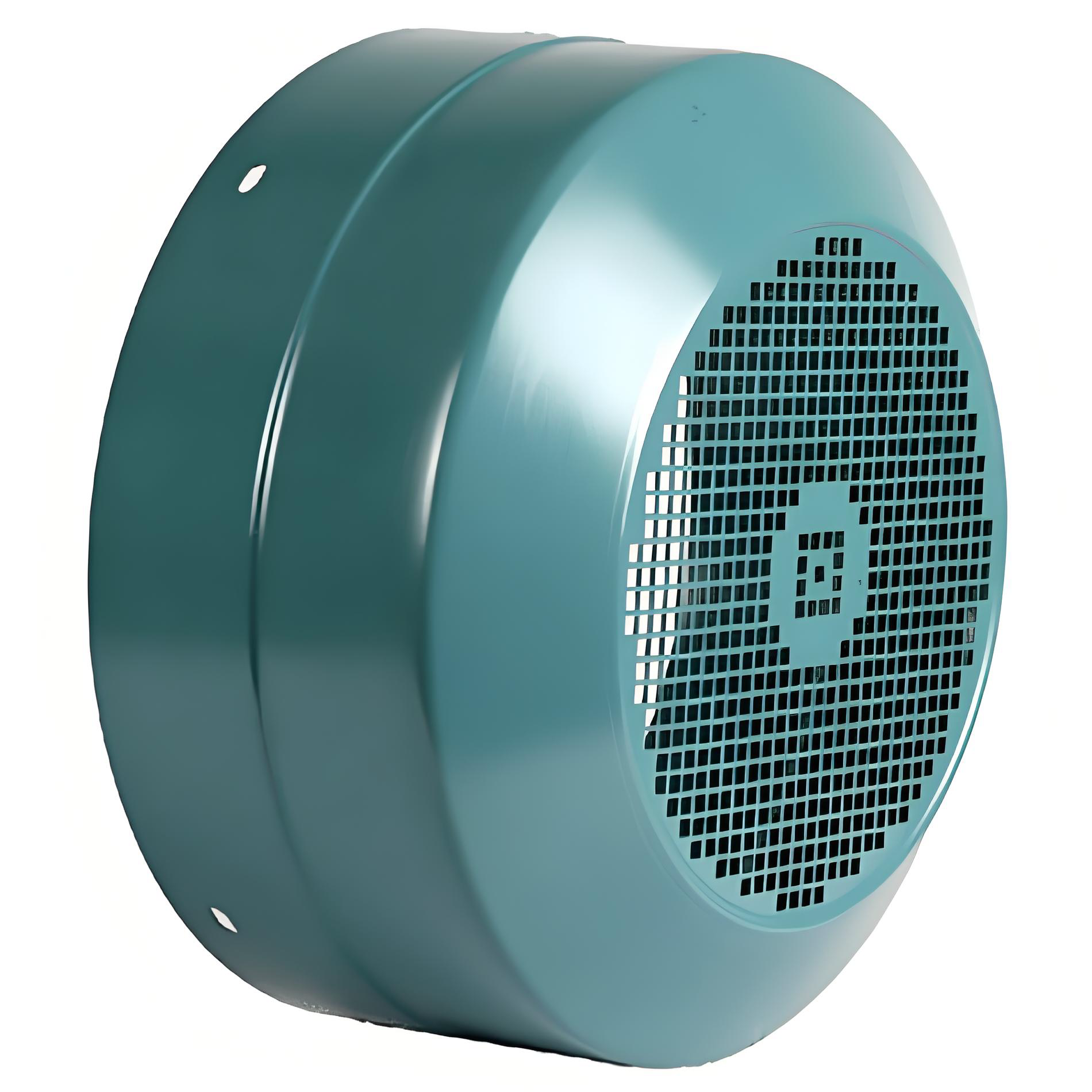

- Simo Motor Fan Cover: The Perfect Combination of Efficient Heat Dissipation and Quiet Operation

Simo motorsAirflow Cover: The Perfect Combination of Efficient Heat Dissipation and Quiet Operation

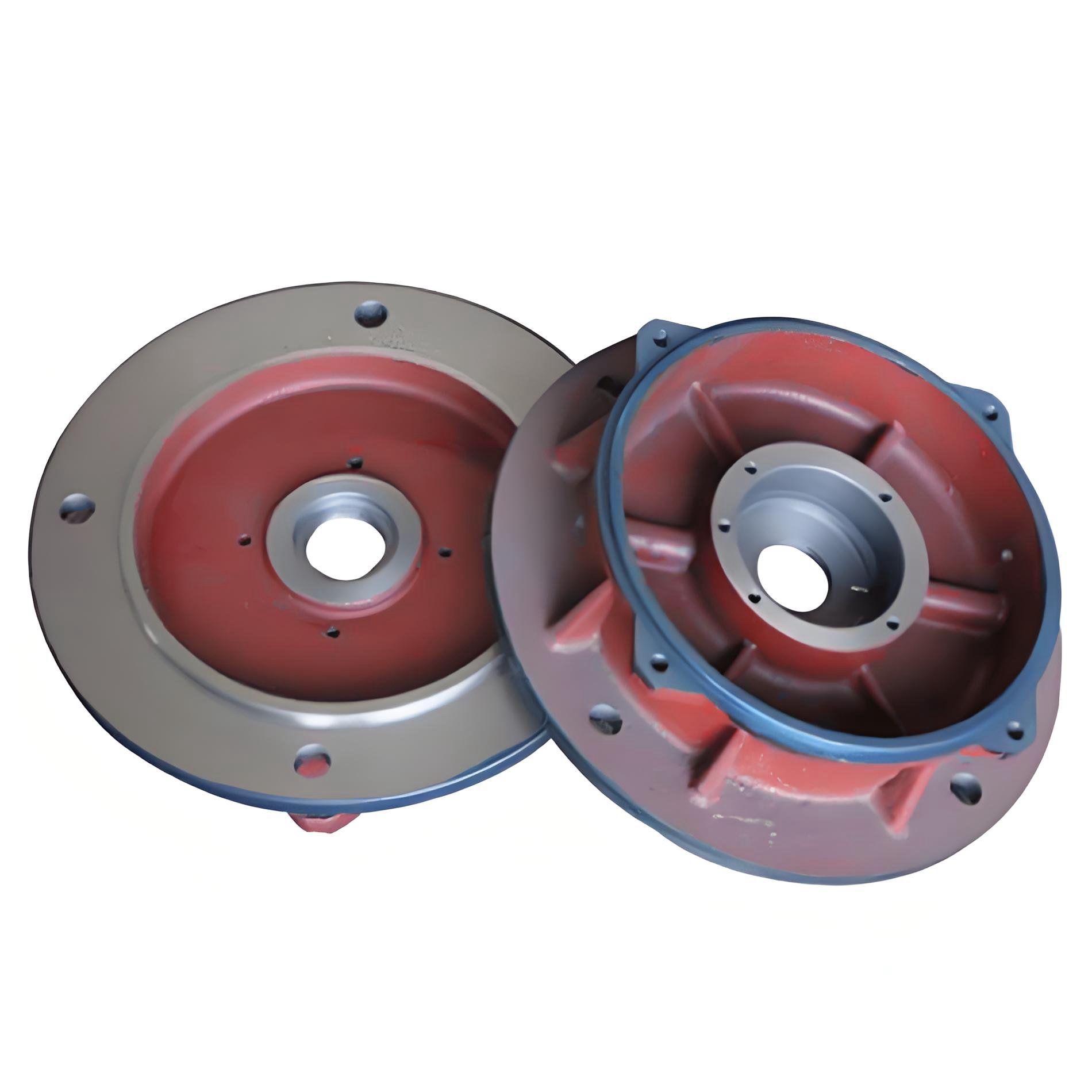

Within the product portfolio of Simo Motors,Motor Fan CoverAlthough it is a structural component, it plays a crucial role in the motor'sHeat dissipation efficiency, protective safety, and service lifeplays a crucial role.

Simo motor windshieldSpecifically designed for various types of electric motorsHigh-Efficiency Heat Dissipation and Safety Protection DevicethroughScientific ventilation design and precision manufacturing processeseffectively enhances motor heat dissipation efficiency, ensuring stable operation at optimal temperatures. This product utilizesPremium materials and innovative structural designpossessHighly protective, highly ventilated, robust construction, aesthetically pleasing, easy to installFeaturing characteristics such as high efficiency, low noise, and low vibration, these products are widely used in various industrial fans, electric motor equipment, and ventilation systems.

I. Product Overview and Core Features

The Simo motor fan cover is for electric motors.Heat Dissipation System and Safety ProtectionA key component whose primary function is toReasonable ventilation design和Protective StructureWhile ensuring adequate heat dissipation for the motor, it effectively prevents external foreign objects from entering the motor interior, guaranteeing the equipment operates inA safe and stable environmentOperating in China.

The Simo motor fan cover adoptsOptimized Vent Design和Robust frame structurecan bothMaximize ventilation areaPromote airflow while alsoMaintain structural strengthResist external impacts. Depending on different application requirements and motor types, Simo Motors providesMultiple materials, specifications, and installation methodsEach design of our windshield products undergoes rigorous testing to ensure reliable performance across diverse environmental conditions.。

II. Core technology features and performance advantages

1. Innovative Noise Reduction Design

The Simo motor fan shroud incorporates multiple innovative technologies for noise control:

- Noise Reduction Structural DesignBased on the motor's airflow characteristics, intake and exhaust ports are reserved in the air shroud housing, with the cold air zone and hot air zone separated by partitions.。

- Acoustic Material ApplicationsInstall sound-absorbing materials at the points of maximum noise radiation to preemptively reduce noise, effectively lowering the noise level during motor operation.。

- Streamlined duct designTo mitigate increased motor temperature rise caused by heightened air resistance from added sound-absorbing materials, the baffles and air guide plates are streamlined to reduce air resistance, enabling smoother airflow within the hood.。

2. High-efficiency heat dissipation performance

The Simo motor fan cover offers significant advantages in heat dissipation efficiency:

- Optimized Ventilation System: ByScientific Ventilation Opening Layout和Reasonable airflow guidance designEnsure that heat generated during motor operation is dissipated promptly.。

- Mixed Ventilation TechnologyReplace the traditional radial ventilation system withAxial-Radial Mixed Ventilation SystemDetermine the optimal length for each segment of the iron core based on heat dissipation conditions to significantly enhance cooling efficiency.。

- Smart Airflow DesignThe internal air ducts of the fan shroud efficiently dissipate internal heat while reducing noise, ensuring adequate heat dissipation for the motor under an IP24W protection rating.。

3. Sturdy and durable construction

The structural design and material selection of Simo motors' fan covers prioritize long-term reliability:

- Premium Material Selection: AdoptionHigh-strength steel或Premium Aluminum Alloycombining excellent structural strength with corrosion resistance。

- High protection ratingStandard product protection rating reachesIP55Effectively prevents dust ingress and water spray, suitable for harsh industrial environments.。

- Excellent temperature resistance: the ability toAmbient temperature shall not exceed 40°C.Stable operation under high-temperature conditions, suitable for high-temperature industrial environments。

III. Technical Parameters and Specifications

Simo motors' fan covers encompass a wide range of technical specifications to meet the demands of diverse application scenarios:

Main technical parameters

Product Line and Features

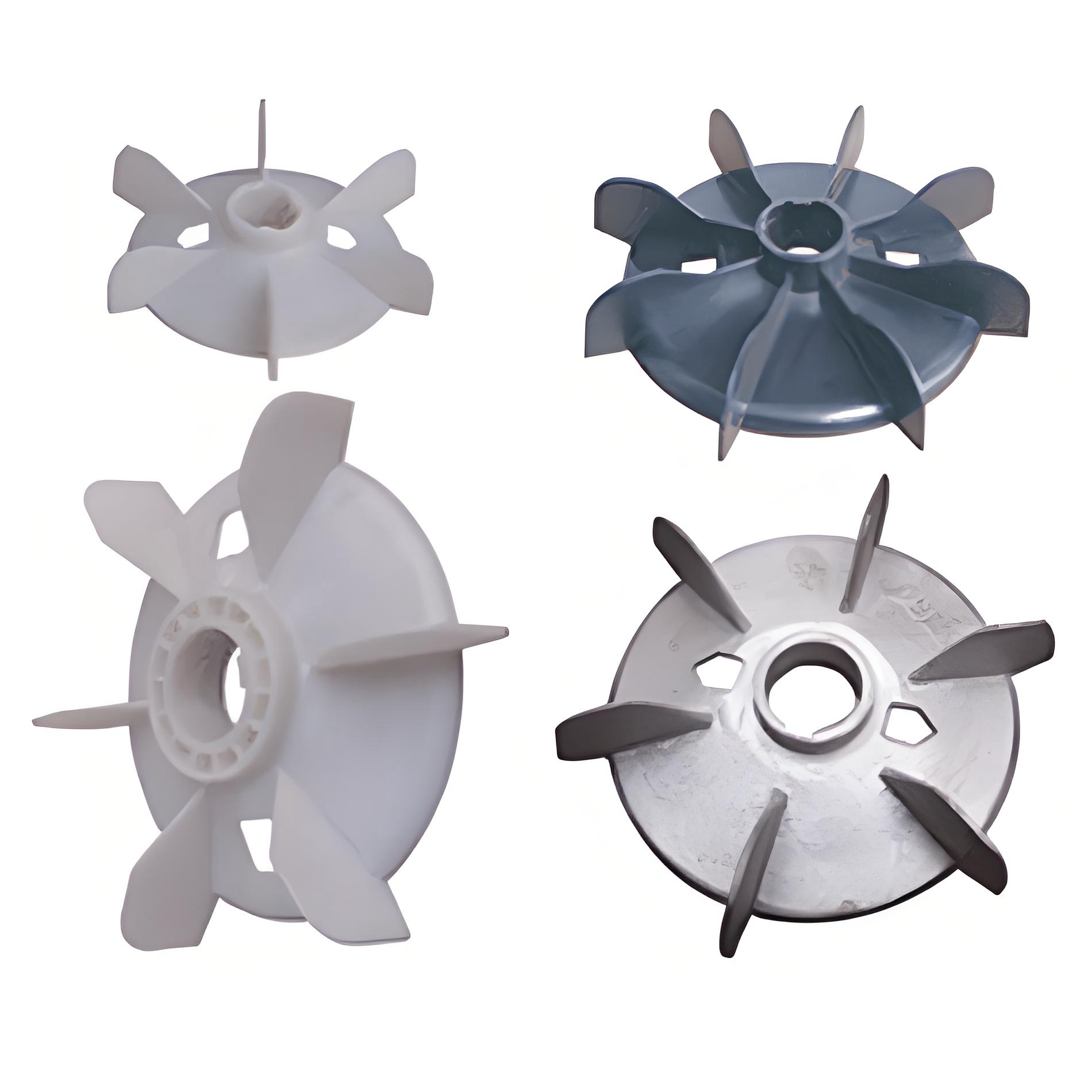

Simo Motor Fan Covers offer multiple product series tailored to different application requirements:

- Standard Hood Series:Suitable for general industrial environments, providingBalanced thermal performance和Economical pricingIt is the ideal choice for most electric motor equipment.

- Low-Noise Fan Cover Series: AdoptionSpecialized sound-absorbing materials and noise-reducing structuresEffectively reduces motor operating noise, suitable for environments with stringent noise control requirements.。

- High-Protection Windshield Series: Has the followingHigher protection rating和Enhanced dustproof and waterproof designSuitable for harsh environments such as high dust and humidity conditions。

- Variable Frequency MotorSpecialized Air Hood SeriesSpecifically designed for variable-frequency drive motors, it meets the cooling demands of motors at different speeds while maintaining highly efficient heat dissipation performance.

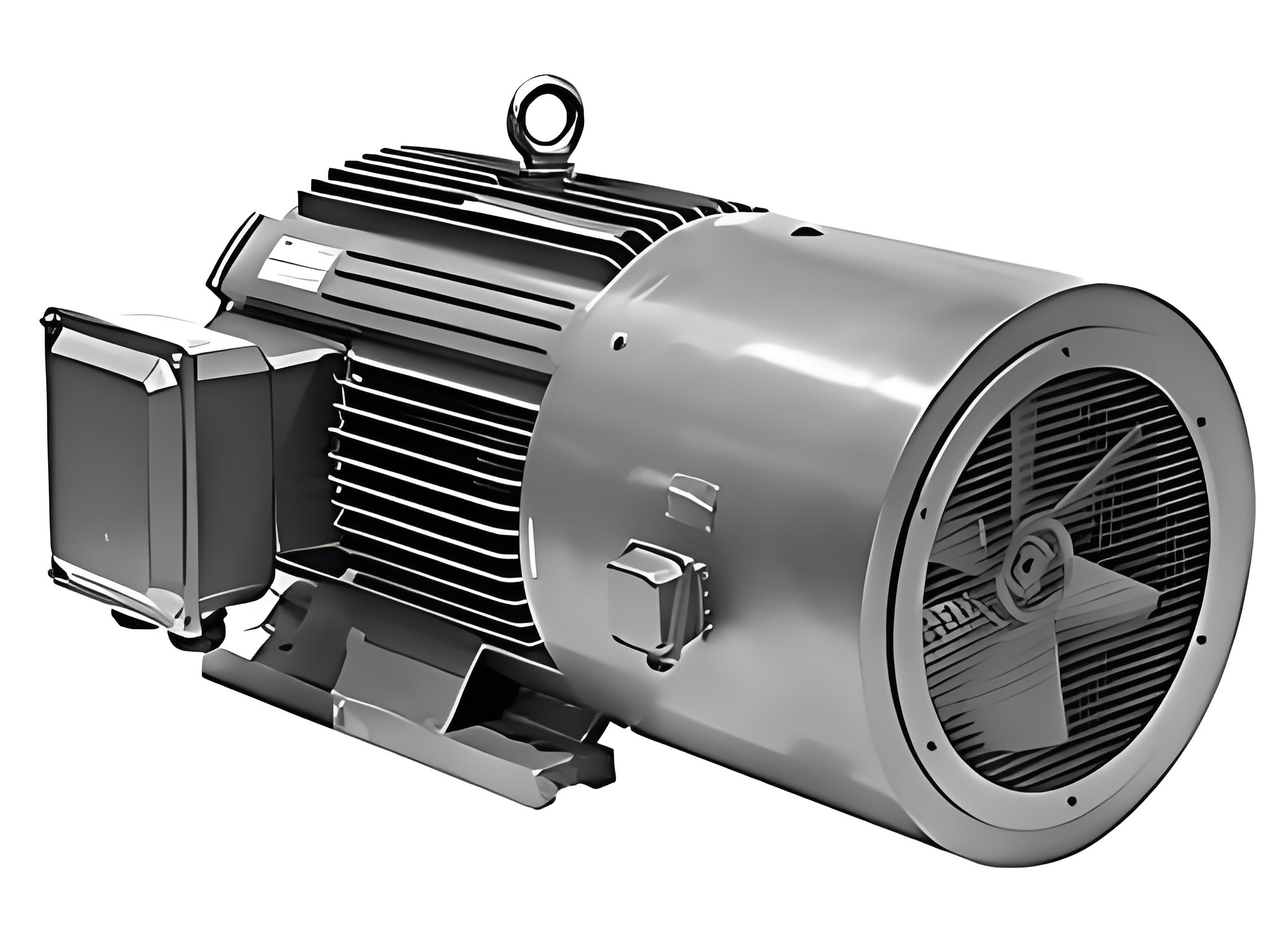

IV. Application Areas and Industry Solutions

Simo Motor Fan Covers are widely used across numerous industrial sectors due to their reliable performance and diverse designs:

1. Industrial Manufacturing Sector

- Power industry: forBoiler Ventilation System、Dust Extraction Fan及Generator Set Cooling SystemEnsure the stable operation of electrical equipment.。

- Metallurgical industry: Applied toSintering Fan、Dust Extraction Fan及Ventilation System for Smelting EquipmentWithstands high temperatures and high-dust environments.

- Building materials industry: Applicable toCement Production Line、Glass Manufacturing Equipment及Ceramic Production Machineryventilation and heat dissipation requirements.

2. General industrial and civil applications

- Industrial Fan EquipmentWidely used inCentrifugal fan、Axial-flow fan及Ventilation EquipmentProviding reliable ventilation solutions for all types of industrial facilities.

- Motor accessoriesFor various modelsIndustrial Electric MotorProvides an efficient heat-dissipating shroud to ensure the motor operates continuously for extended periods without overheating.。

- Pumps and CompressorsApplicable to all typesWater pumps, air compressorsProtecting motors and ensuring heat dissipation for equipment extends their service life.

3. Special Environment Applications

- High-temperature working environment: Applicable toBoiler Induced Draft Fan、High-Temperature Flue Gas Treatment SystemIn high-temperature environments, it delivers stable and reliable performance.。

- Highly dusty environments: forDust Extraction Fan、Mine Ventilation EquipmentExcellent protective performance in high-dust-content operating conditions。

- humid environment: Applied toUnderground Engineering、Offshore platformIn humid environments, it offers outstanding corrosion resistance.。

V. Selection and Installation Guide

1. Selection Criteria

Selecting the appropriate Simar motor fan cover requires comprehensive consideration of the following factors:

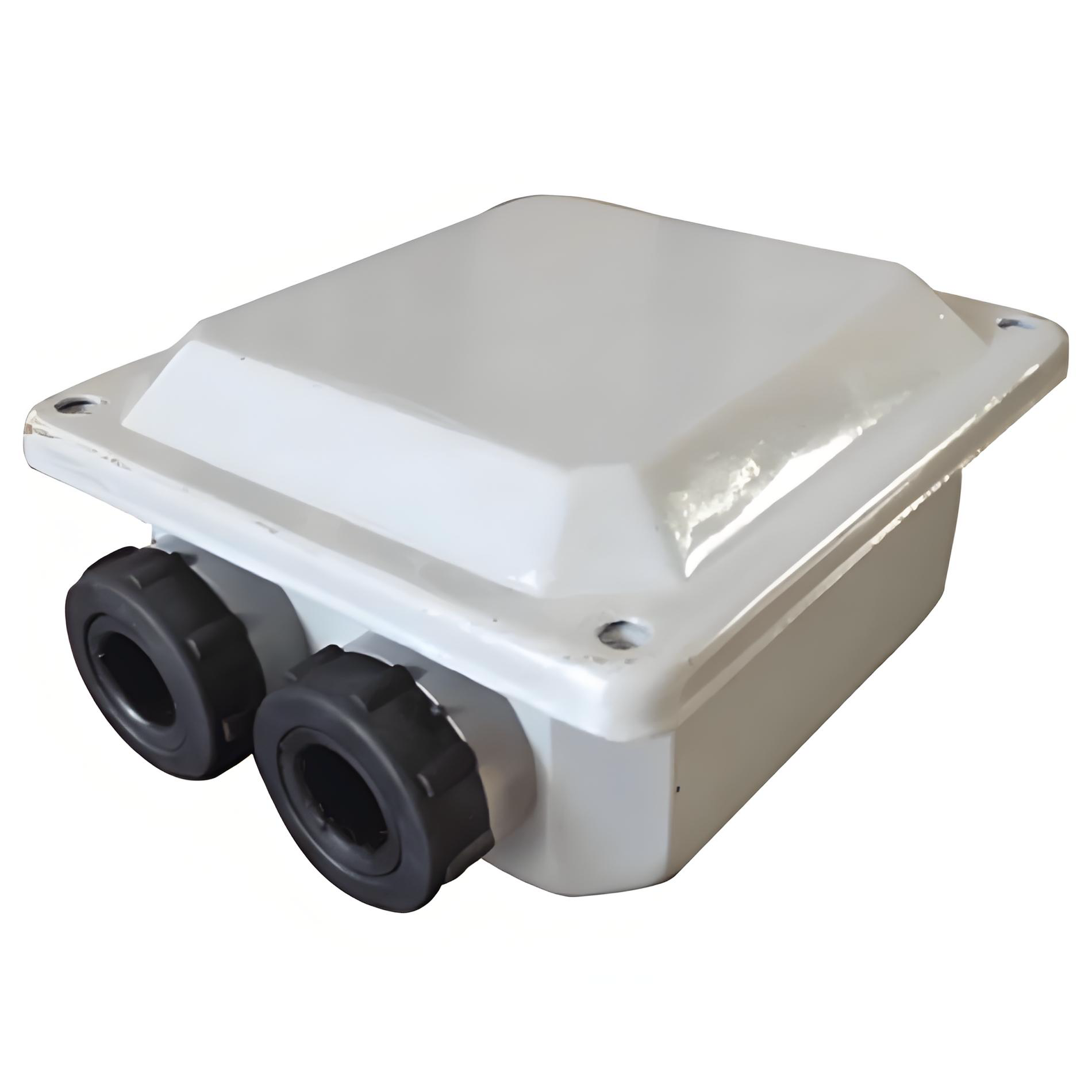

- Motor ParametersAccording to the motor'smodel number、power (output)、number of revolutions per minute及seat numberSelect the appropriate hood specifications.

- Operating Environment:: Considerationsenvironmental temperature、humidity level、Dust concentration及Corrosive Substance ContentTo determine the appropriate material and level of protection。

- Heat dissipation requirementsBased on the motor'sHeat output和work systemDetermine the required ventilation area and heat dissipation capacity.。

- Space constraints:: ConsiderationsInstallation space sizeSelect a properly sized fan shroud to ensure it does not interfere with other components.

2. Installation Notes

Proper installation is the foundation for ensuring the hood functions correctly:

- Inspection and PreparationBefore installation, carefully inspect the air duct.Is there any noticeable deformation?,Are all welded joints secure?。

- Centered and fixedEnsure the fan shroud is properly secured to the motor.Centered accuratelyAfter installationNo noticeable shakingEnsure a secure connection.

- Sealing treatment: Take appropriate measures at the connection points.Sealing measuresPrevent air leakage and the ingress of water and dust。

VI. Maintenance and Troubleshooting

1. Periodic inspection and maintenance

Maintenance of the Simo motor fan cover is relatively straightforward and primarily includes:

- Regular cleaningRegularly clean the ventilation openings on the air intake hood.Dust and greaseEnsure proper ventilation to maintain effective heat dissipation.

- Inspect for corrosion: Regularly inspect the air intake hood.Corrosion ConditionEspecially in applications involving humid and corrosive environments, prompt action is required.

- Connection CheckCheck the fan shroud and motor.Is the connection secure?Check whether the bolts are loose to ensure the overall structure remains stable.

2. Common Troubleshooting

Common Issues and Solutions Encountered During the Use of Wind Covers:

- Poor ventilation: Typically byVentilation holes blockedTo resolve this issue, clean the ventilation openings and restore the ventilation area.

- Abnormal Vibration: InspectionAre the fixing bolts loose?或Is the air duct deformed?Tighten or replace as necessary.

- Premature corrosionIn corrosive environments, the following should be considered:Replace with more corrosion-resistant materialThe windshield may be surface-treated.

VII. Service and Support

Simo Electric provides comprehensive technical support and service assurance for its fan hood products:

- Specialized technical consulting:Provide professional consulting services for product selection and application solutions.

- Customized Services: Provided according to customer's special needsPersonalized Design and Manufacturing Servicesto meet specific application requirements.

- Perfect after-sales protection:Provide quality assurance and after-sales service to ensure worry-free customer experience.

- Adequate inventory guaranteeStandard motors are available.Large quantities of windshields and other accessories in stockMeet customers' urgent needs.

The Simo motor fan shroud, with itsScientific design、Premium materials和Precision manufacturing processbecome the driving force for various types of electric motors and ventilation equipment.Ideal Thermal Management and Protection SolutionsWhether it beGeneral industrial applicationsorHarsh special environmentsSimo Motors can provide motor covers.Reliable performance和Long service life。

Choosing Simo Motor's fan shroud means choosingReliable thermal management和Long-lasting operational performanceWe look forward to collaborating with you to provide the optimal thermal management and protection solutions for your equipment.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206