Article Catalog[Hidden]

- Xima Motor Fan Blades: The Perfect Combination of Outstanding Performance and Long-Lasting Durability

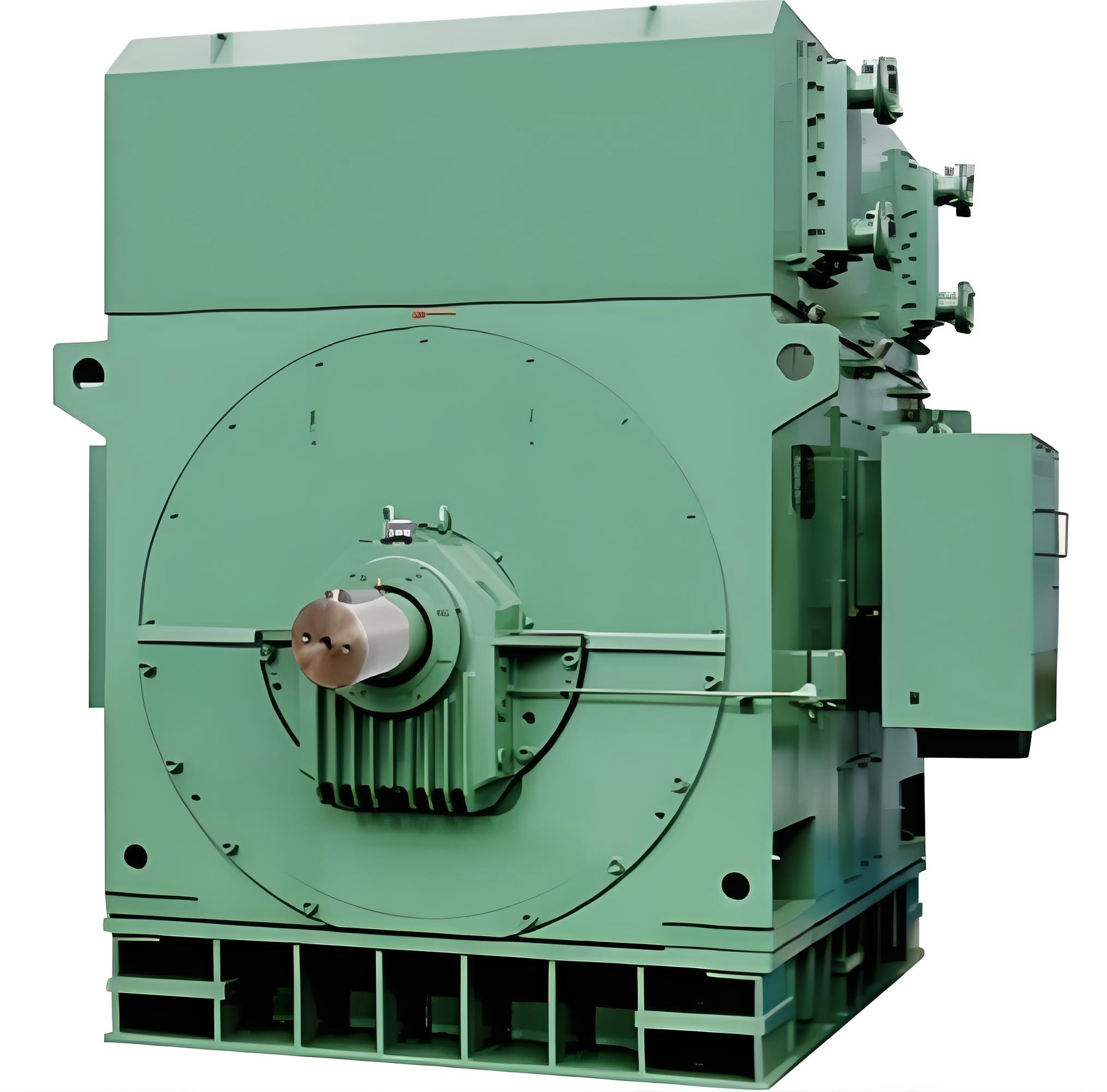

Simo motorsFan Blades: The Perfect Combination of Outstanding Performance and Long-Lasting Durability

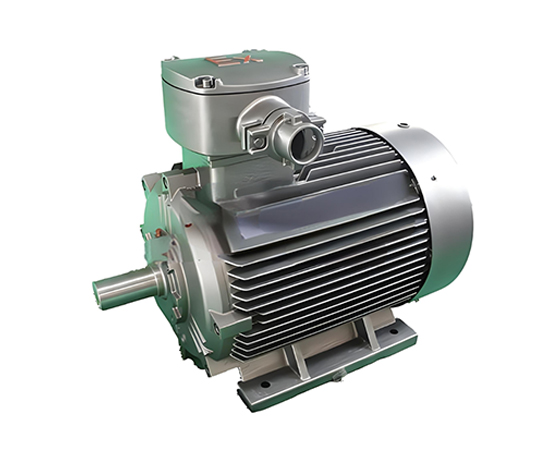

As a core component of electric motors, Xima motor fan blades are characterized by theirOutstanding thermal performance和Long-lasting and stable performancemaking it an ideal choice for various industrial equipment and electric motor products.

Simo Motor Wind BladeSpecifically designed for various types of electric motorsHigh-efficiency heat dissipation devicethroughScientifically designed aerodynamics和Precision Manufacturing Processeffectively enhances motor heat dissipation efficiency, ensuring stable operation at optimal temperatures. This product utilizesQuality materials和Innovative Structural DesignpossessCorrosion-resistant, high strength, low noise, high efficiency, aesthetically pleasing, easy to installFeatures such as these make it widely applicable in various industrial fans, motor equipment, and ventilation systems.。

I. Product Overview and Core Features

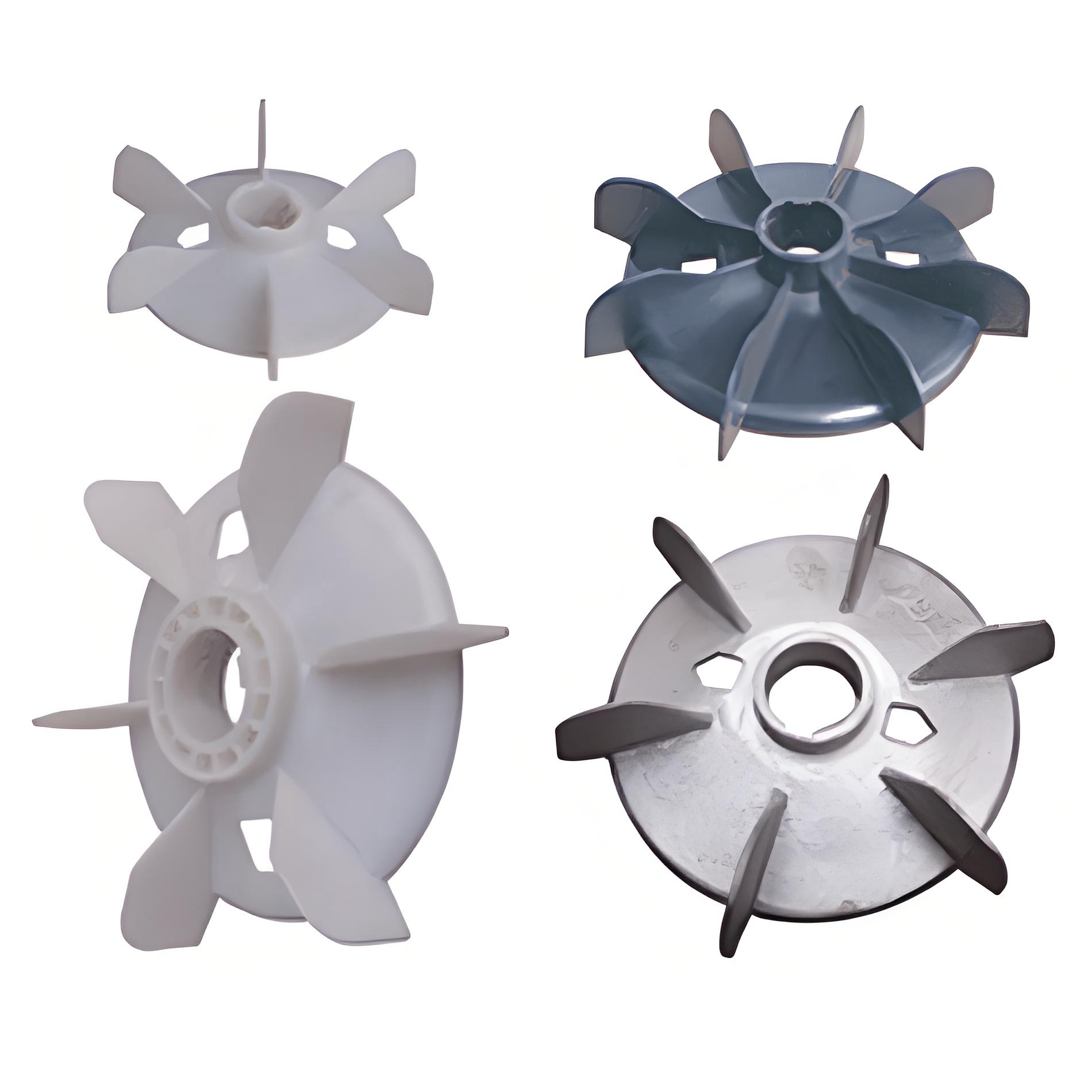

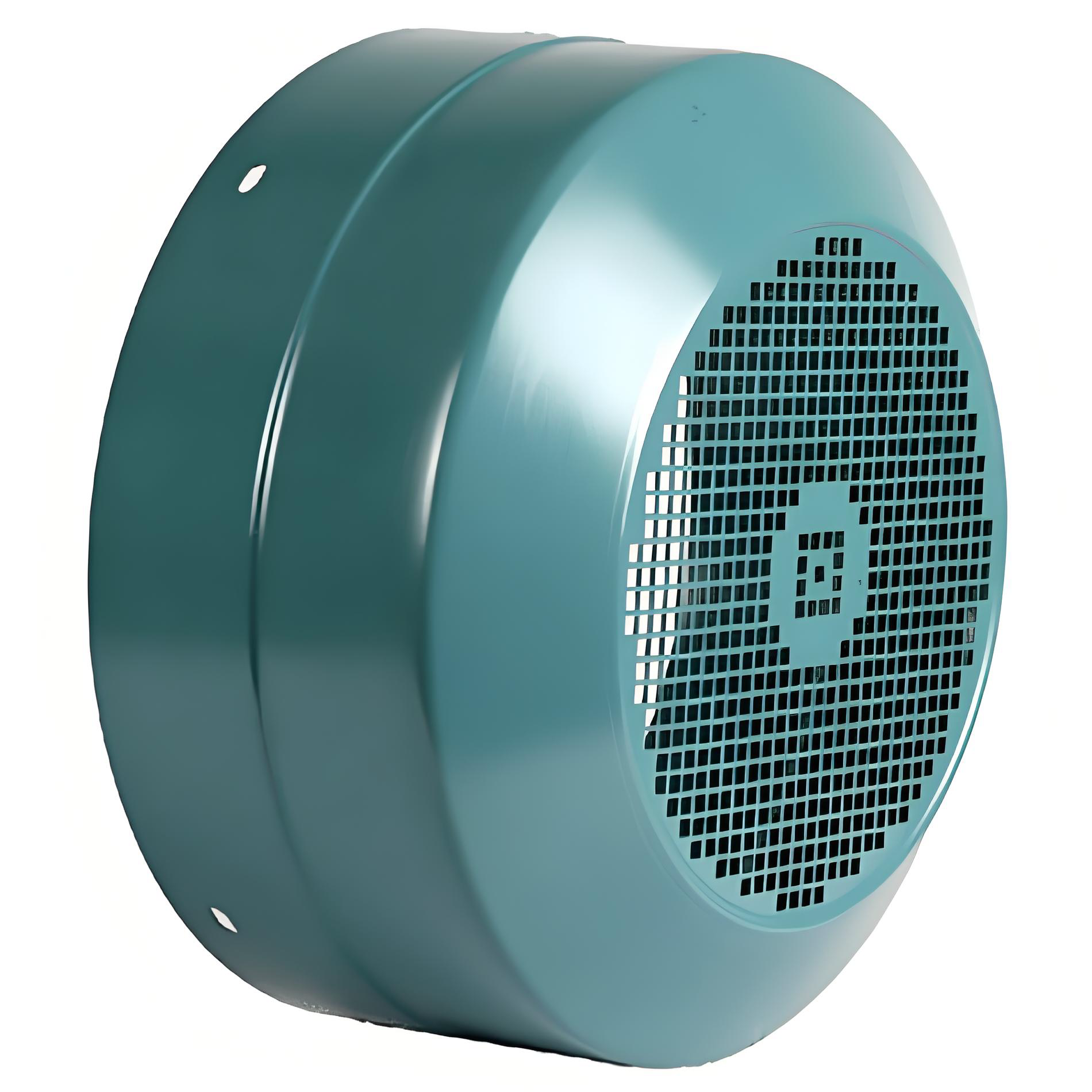

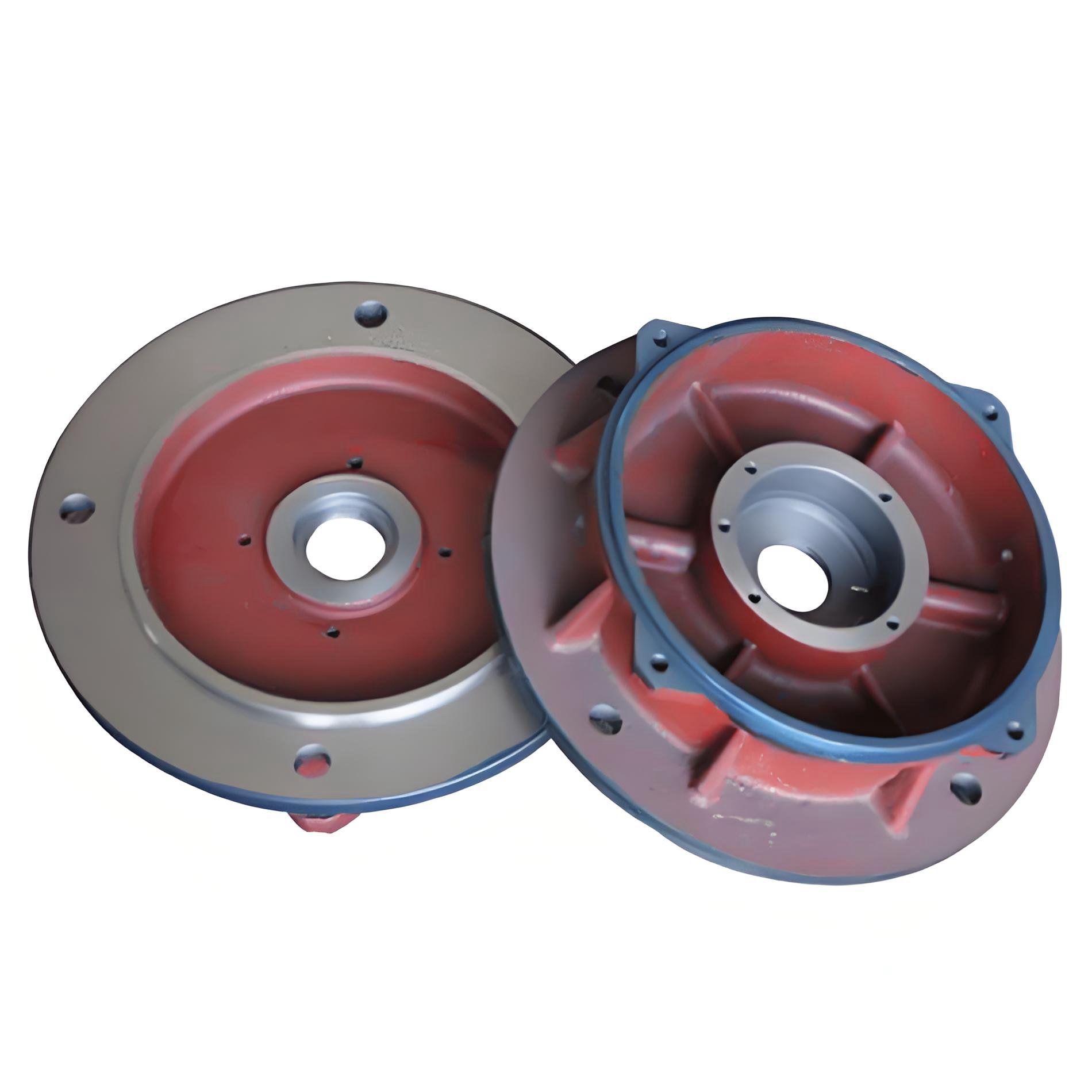

The fan blades of the Xima motor are part of the motor's cooling system.Key componentsIts primary function is toForced air convectionThe cooling system effectively dissipates heat generated during motor operation, preventing overheating and ensuring the equipment operates within its optimal temperature range. Depending on specific application requirements and motor types, Xima Motors providesPlastic fan blades, aluminum fan blades, iron fan bladesThree primary material options, each offering distinct performance advantages to meet usage requirements in diverse environmental conditions.。

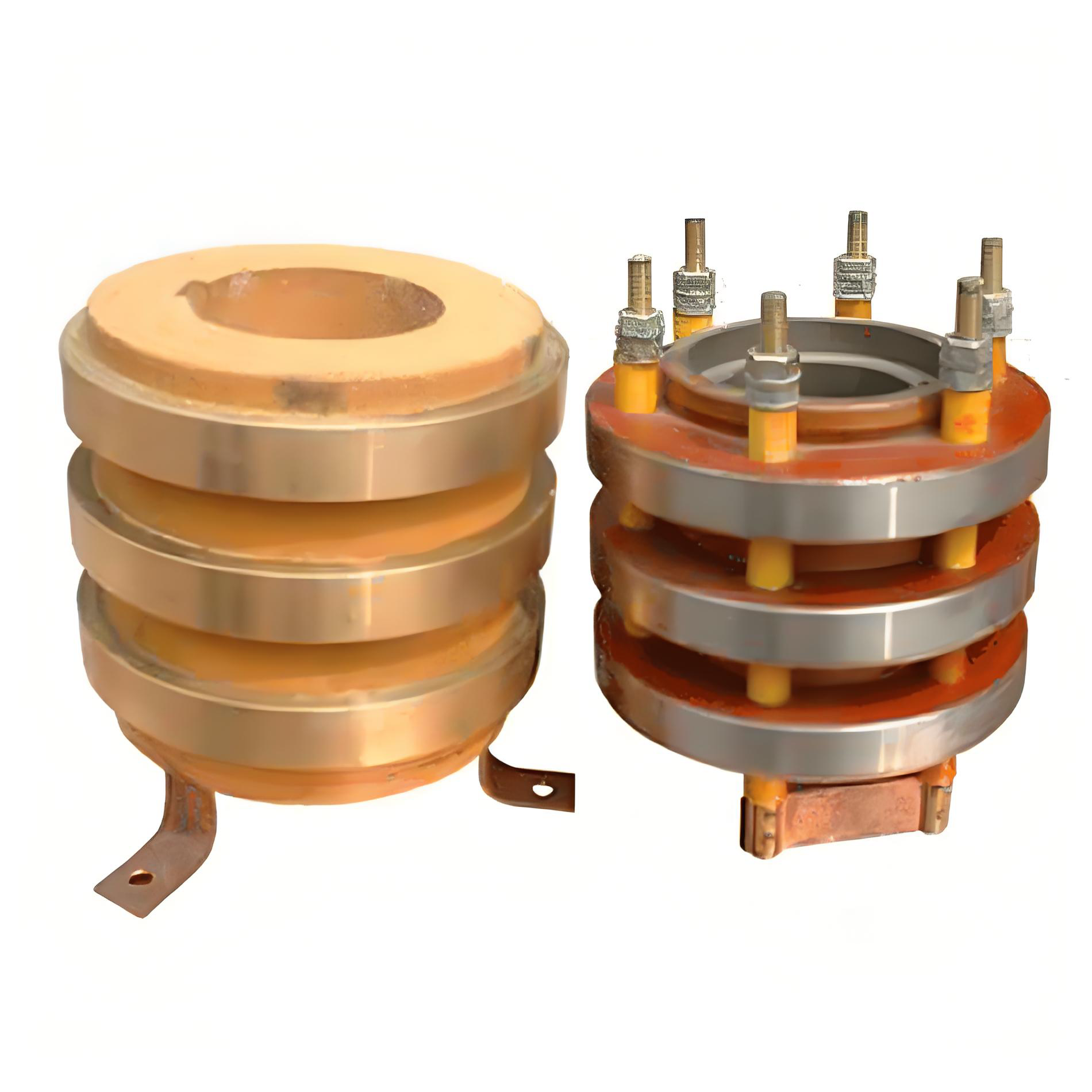

Xima Motor Fan Blades AdoptAdvanced design philosophy和Precision manufacturing technologyBlade angle and surface curvatureAerodynamic OptimizationIt can generate greater airflow and higher static pressure at the same rotational speed, whileSignificantly reduce operating noiseThe product has undergoneStrict dynamic balancing calibrationEnsure smooth operation at high rotational speeds with minimal vibration, effectively extending the motor's service life.。

II. Technical Features and Performance Advantages

1. Premium materials and robust construction

Xima motor fan blades offer significant advantages in material selection and structural design:

- Multiple Material Options: ProvidedPlastic (PA6.6), aluminum alloy, ironVarious materials for fan blades, including plastic bladesReinforced Plastic PA6.6 Injection MoldingOn the metal plate, it combines the strength of metal with the lightweight properties of plastic.

- Innovative Structural Design: AdoptionIntegrated design of fan hub and bladesThe blades are evenly distributed along the outer circumference of the fan hub, throughWelding, bonding, and other permanent joining methodsIntegrating the blades with the fan hub ensures excellent overall balance.

- Surface treatment technologyThe surface of the metal fan blades has undergoneSpecial processingEnhances corrosion resistance and wear resistance, suitable for harsh working environments

2. Superior Performance and Efficient Heat Dissipation

Xima motor fan blades also deliver outstanding performance:

- High-efficiency heat dissipation capability: ByOptimized blade angle and surface designAchieve higher airflow and pressure to enhance cooling efficiency.

- Low-noise operation: AdoptionNoise Control TechnologyRuns smoothly with significantly lower noise levels than comparable products, providing a more comfortable working environment.

- Energy Conservation and Environmental Protection:Excellent pneumatic designReduced fan blade rotational resistance enables lower energy consumption while maintaining equivalent cooling performance, aligning with green and eco-friendly principles.

3. Long service life and reliable performance

Xima Motor Fan Blades emphasize product durability and reliability:

- High-strength wear resistanceThe blade surface undergoes special treatment, featuringHigh hardness and wear resistancecan maintain a long service life even in dusty gas environments

- Dynamic Balancing AssuranceEach fan blade has undergoneHigh-standard dynamic balancing calibrationEnsure stability during high-speed operation while minimizing vibration and noise.

- environmental adaptation: the ability to-20°C to 60°COperates stably under ambient temperatures, with some models capable of adapting to even broader temperature ranges.

III. Technical Parameters and Specifications

Xima motors' fan blades cover a wide range of technical specifications to meet the needs of various application scenarios:

Main technical parameters

Product Line and Features

Xima Motor Fan Blades offer multiple product series tailored to different application requirements:

- Standard Fan Blade Series:Suitable for general industrial environments, providingBalanced performance和Economical pricingis the ideal choice for most electric motor equipment

- High-Temperature Resistant Fan Blade Series: AdoptionSpecial Materials and Structural DesignMaintains stable performance in high-temperature environments, suitable for equipment such as boiler induced draft fans and high-temperature fans.

- Corrosion-Resistant Fan Blade Series:AfterSpecial Surface Treatmentwith excellent corrosion resistance, suitable for corrosive environments such as chemical and metallurgical industries

- High-Strength Wear-Resistant Fan Blade SeriesThe surface of the blades has undergoneSpecial Hardening TreatmentHardness can reach HRC 60–70, extending impeller life by more than three times and making it suitable for high-dust-content operating conditions.

IV. Application Areas and Industry Solutions

Xima Motor fan blades are widely used across numerous industrial sectors due to their reliable performance and diverse designs:

1. Industrial Manufacturing Sector

- Power industry: forBoiler Ventilation System、Dust Extraction Fan及Generator Set Cooling SystemEnsure the stable operation of electrical equipment.

- Metallurgical industry: Applied toSintering Fan、Dust Extraction Fan及Ventilation System for Smelting EquipmentWithstands high temperatures and high-dust environments

- Building materials industry: Applicable toCement Production Line、Glass Manufacturing Equipment及Ceramic Production MachineryVentilation and heat dissipation requirements

2. General industrial and civil applications

- Industrial Fan EquipmentWidely used inCentrifugal fan、Axial-flow fan及Ventilation EquipmentProviding reliable ventilation solutions for all types of industrial facilities

- Motor accessoriesFor various modelsIndustrial Electric MotorEquipped with high-efficiency cooling fan blades to ensure the motor operates continuously for extended periods without overheating.

- Civil Ventilation Equipment: Applied toLarge exhaust fan、Water-cooled fan、Factory Cooling SystemCivilian and commercial premises

3. Special Environment Applications

- High-temperature working environment: Applicable toBoiler Induced Draft Fan、High-Temperature Flue Gas Treatment SystemIn high-temperature environments, it delivers stable and reliable performance.

- Highly dusty environments: forDust Extraction Fan、Mine Ventilation EquipmentIn high-dust-content operating conditions, it exhibits outstanding wear resistance.

- Corrosive environment: Applied toChemical processing equipment、Wastewater Treatment SystemIn corrosive atmospheres, it exhibits outstanding corrosion resistance.

V. Selection and Installation Guide

1. Selection Criteria

Selecting the appropriate fan blades for Xima motors requires comprehensive consideration of the following factors:

- Motor ParametersAccording to the motor'smodel number、power (output)、number of revolutions per minute及seat numberSelect the appropriate fan blade specifications

- Operating Environment:: Considerationsenvironmental temperature、humidity level、Dust concentration及Corrosive Substance ContentDetermine the appropriate material and type

- Performance Requirements: Based onHeat dissipation requirementsDetermine the required airflow and pressure, then select the fan blade model that meets the cooling requirements.

- Space constraints:: ConsiderationsInstallation space sizeSelect appropriately sized fan blades to ensure they do not interfere with other components.

2. Installation Notes

Proper installation is the foundation for ensuring the fan blades operate correctly:

- Inspection and PreparationBefore installation, carefully inspect the fan blades.Is there any noticeable deformation?,Does the fan blade rotate smoothly and freely?

- Center and BalanceEnsure the fan blades are aligned with the motor shaft.Centered accuratelyAfter installationNo noticeable shakingEnsure smooth operation

- Properly tightenTighten to the recommended torque.Prevent excessive tightening from causing internal stress or excessive looseness from causing loosening.

VI. Maintenance and Troubleshooting

1. Periodic inspection and maintenance

Maintenance tasks for Xima motor fan blades primarily include:

- Regular cleaningRegularly clean the surface of the fan blades.Dust and greaseKeep the fan blades clean to ensure effective heat dissipation.

- Inspect for wearRegularly inspect the fan blades.Wear conditionEspecially at the blade edges and leading edges, promptly identify excessive wear.

- Balance Verification:inAfter prolonged operation或Replace the fan bladesPerform dynamic balancing verification to ensure smooth operation.

2. Common Troubleshooting

Common Issues and Solutions for Fan Blade Usage:

- Excessive vibration: Typically byUneven dust accumulation或Balance disruptionCaused by the need for cleaning and rebalancing

- Abnormal NoiseCheck forForeign body contact或Bearing wearPromptly clean or replace damaged components.

- Airflow reduction: It may be due toBlade deformation或Excessive dust accumulationThe fan blades need to be cleaned or replaced.

VII. Service and Support

Xima Electric provides comprehensive technical support and service assurance for fan blade products:

- Specialized technical consulting:Provide professional consulting services for product selection and application solutions

- Customized Services: Provided according to customer's special needsPersonalized Design and Manufacturing ServicesManufacturing custom-shaped fan blades

- Perfect after-sales protection: Provide quality assurance and after-sales service to ensure worry-free use by customers

- Adequate inventory guaranteeStandard motors are available.Large quantities of fan blades and other accessories in stockMeet customers' urgent needs

Xima Motor Fan Blades, with theirScientific design、Premium materials和Precision manufacturing processbecome the driving force for various types of electric motors and ventilation equipment.Ideal Thermal SolutionWhether it beGeneral industrial applicationsorHarsh special environmentsSimar Motors can supply all types of fan blades.Reliable performance和Long service life。

Choosing Xima Motor fan blades means choosingReliable thermal management和Long-lasting operational performanceWe look forward to working with you to provide the optimal thermal management solution for your equipment.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206