Anchoring green intelligent manufacturing, Simo motor parts become the core support

Date: 2023-08-21 Categories: Motor knowledge Views: 1067

Article Catalog[Hidden]

- Xima Motor Components Become Core Support

- Technical Advantages: Breakthroughs across multiple dimensions, demonstrating professional technical prowess.

- Application Scenarios: Cross-industry empowerment, with proven results demonstrated through case studies.

- Industry and Policy Alignment: Adapting to Policy Trends to Address Industry Pain Points

- Market and Future: Global Expansion, Dual Advancement in Technology and Applications

Simo motorsAccessories become the core support

Currently, the global manufacturing sector is accelerating its transition toward greener and smarter operations. China's “dual carbon” goals and Industry 4.0 strategy are advancing in tandem. As the core power source for industrial production and the new energy sector, motors face increasingly urgent demands for efficient operation and intelligent upgrades.As a critical component of motor systems, Xima Motor Accessories not only serve as the core power support ensuring efficient and energy-saving motor operation but also function as essential supporting components driving the intelligent upgrade of industrial equipment. From core motor transmission to intelligent monitoring, they comprehensively align with green manufacturing and smart manufacturing trends, providing core assurance for optimizing motor systems across various industries.

Technical Advantages: Breakthroughs across multiple dimensions, demonstrating professional technical prowess.

In terms of energy efficiency enhancement, the high-efficiency silicon steel laminated cores in Xima motor components strictly adhere to the GB 18613-2020 Class 1 energy efficiency motor standard. Utilizing 30Q130 high magnetic flux density, low-loss silicon steel material, the core laminations achieve a stacking coefficient exceeding 97.1% through precision stacking techniques.Core losses are reduced by 15% to 20% compared to traditional components. When paired with optimized winding coil components, overall motor operating efficiency improves by 3% to 5%, significantly reducing energy waste in industrial production.

In the field of intelligent control, Xima Motor Accessories achieves deep IoT integration. Its developed smart sensor accessories collect real-time critical data such as motor speed, stator temperature, and bearing vibration frequency with sampling accuracy reaching ±0.1%. Through RS485/4G communication modules, they connect with cloud management platforms to support remote monitoring, parameter debugging, and fault early warning.Additionally, the compatible smart drive module accessories support both PLC and industrial Ethernet protocols, enabling seamless integration into factory MES systems. This facilitates the intelligent transition of motor operations and maintenance from “reactive repair” to “predictive maintenance.”

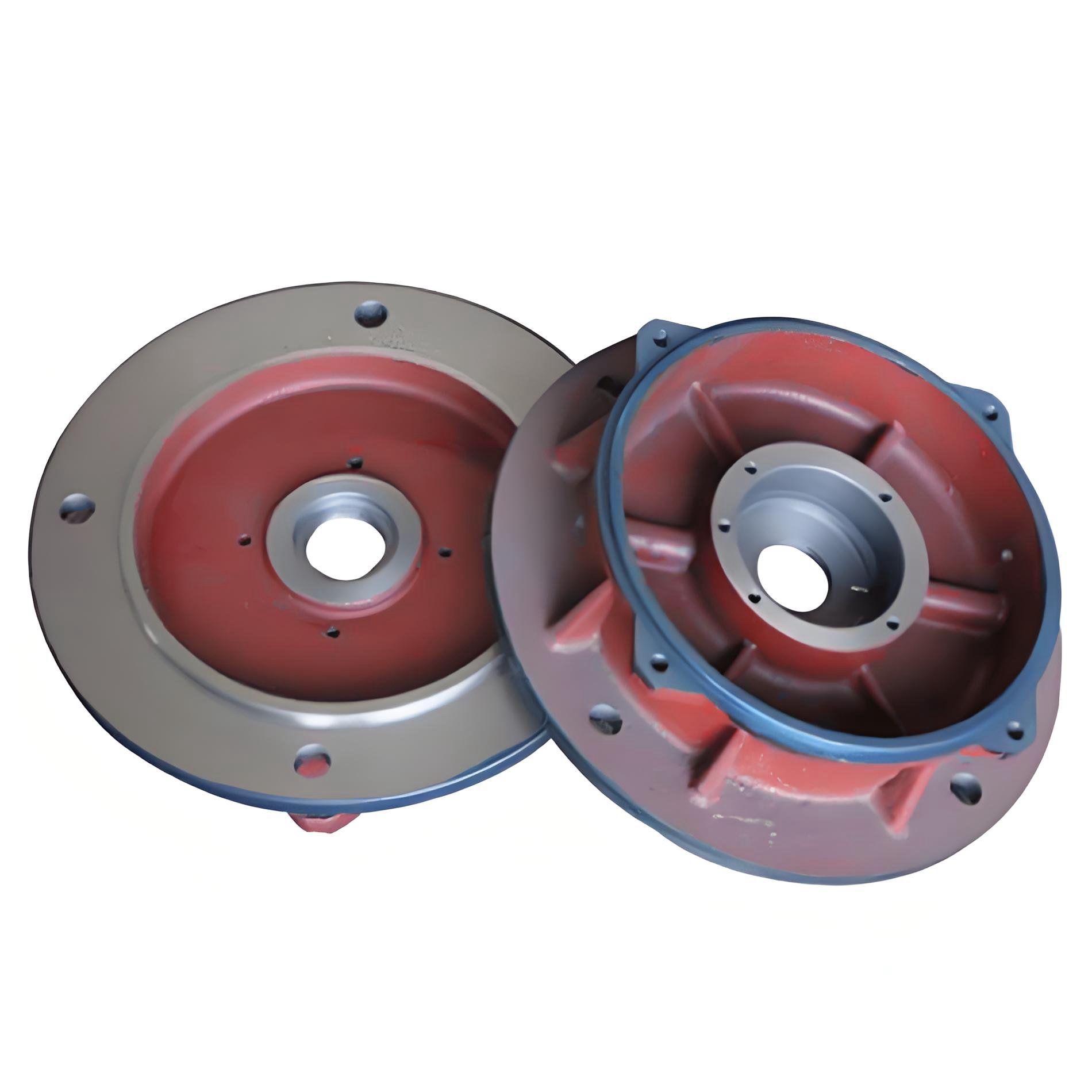

In terms of environmental performance, Xima Motor Components fully adopts green manufacturing processes.Motor End CapStructural components such as bearing housings utilize recyclable aluminum alloys and high-strength cast iron, achieving a material recycling rate exceeding 90%.Winding insulation employs low-VOC eco-friendly epoxy resin coatings, reducing volatile organic compound emissions during production by 40% compared to industry standards. Surface treatment processes for components eliminate traditional electroplating in favor of chromium-free passivation technology, achieving low-carbon environmental performance throughout the entire lifecycle and perfectly aligning with green factory construction requirements.

In terms of reliability, Xima motor components have undergone rigorous environmental testing. High-temperature-resistant winding components utilize Class F insulation material with a maximum temperature rating of 155°C. Paired with IP65-rated sealed end cover components, they ensure stable operation in extreme temperature and humidity conditions ranging from -30°C to 80°C.Bearing components utilize high-purity bearing steel and specialized lubricants, reducing wear rates by 30%. With a Mean Time Between Failures (MTBF) exceeding 20,000 hours, they meet the demands of long-cycle, high-load applications in wind power generation and rail transit systems.

Application Scenarios: Cross-industry empowerment, with proven results demonstrated through case studies.

In the field of industrial automation, Xima motor bearing components and stator winding accessories are widely used in conveyor line motors and machine tool spindle motors.After adopting Xima's high-precision bearing components, an automotive parts manufacturer achieved radial runout control within 0.02mm for motor operation. Production line motor stalling failures decreased by 80%, while Overall Equipment Effectiveness (OEE) rose from 75% to 92%, resulting in an annual production capacity increase of 150,000 units.

In the new energy vehicle sector, Xima Motor's commutator components and carbon brush assemblies are optimized for high-frequency commutation demands in drive motors. Commutation spark levels are controlled within Grade 1, reducing current losses by 51%.After a leading new energy vehicle manufacturer adopted this component set, the energy conversion efficiency of the drive motor increased by 81%, the NEDC range per vehicle extended by 52 km, and the motor failure rate decreased from 3.21% to 1.81%, reducing annual after-sales costs by 20 million yuan.

In wind power generation applications, Xima Motor's cooling fan components and stator core accessories are compatible with 1.5MW-5MW wind turbine main drive motors. The cooling fan features a biomimetic blade design that increases airflow by 25%. Combined with a high-efficiency silicon steel core, it effectively addresses high-altitude, high-temperature overload issues in wind turbine motors.In an application at a wind farm in Inner Mongolia, this accessory set increased the annual operating hours of wind turbines from 2,200 to 2,320 hours. This resulted in an annual power generation increase of approximately 35,000 kWh per turbine, shortening the project's investment payback period by 6 months.

In the rail transit sector, Xima Electric's wear-resistant gear components and vibration damping assemblies are engineered for the high-frequency start-stop cycles and vibration-impact characteristics of subway traction motors. Gear surfaces undergo carburizing and quenching processes, achieving a hardness of HRC 60-62 and extending wear life by 50%. The vibration damping assemblies feature a nitrile rubber-metal composite structure, delivering an 80% vibration attenuation rate.Following their implementation on a city's Metro Line 3, maintenance intervals for traction motors extended from 6 to 12 months. Annual operational costs per line decreased by 4 million yuan, while train running smoothness scores rose to 98 points.

Industry and Policy Alignment: Adapting to Policy Trends to Address Industry Pain Points

Against the backdrop of the “dual carbon” goals, Xima motor components have become a key driver for industrial enterprises to reduce carbon emissions by lowering motor energy consumption and minimizing production-related carbon emissions.A major chemical enterprise replaced traditional components in over 200 motors across its facility with Xima high-efficiency parts to meet its carbon reduction targets. This initiative reduced annual motor system power consumption from 120 million kWh to 102 million kWh, equating to an annual carbon emissions reduction of 800 tons. The company successfully achieved the annual emission reduction targets set by local authorities.

Aligning with the intelligent transformation trend of Industry 4.0, Xima Motor's smart accessories address the pain points of traditional motor operation and maintenance—slow response, high costs, and difficulty in predicting failures—by deeply integrating with factory digital systems.After implementing Xima's smart sensors and cloud-based monitoring components, a machinery manufacturing plant reduced motor fault response time from 4 hours to 15 minutes. Fault diagnosis accuracy reached 95%, while unplanned equipment downtime decreased by 60%. This enabled the factory to advance toward its “lights-out factory” operational goal.

In response to national new energy industry policies, Xima Motor Components has undertaken customized development for motor requirements in new energy vehicles, wind power, and photovoltaic sectors, addressing the industry-wide challenge of “shortage of highly compatible components.”For instance, in addressing cooling motors for photovoltaic inverters, Xima's developed micro-bearing components and low-noise winding assemblies ensure stable operation in high-temperature, high-dust environments with 100% compatibility. These solutions are now mass-supplied to leading domestic photovoltaic enterprises, enhancing the reliability of photovoltaic power station cooling systems by 30%.

Market and Future: Global Expansion, Dual Advancement in Technology and Applications

In terms of market layout, Xima Motor Parts has established a service network covering core regions across East China, North China, South China, and Northwest China. With two major production bases in Xi'an and Suzhou equipped with 12 automated production lines, the company boasts an annual production capacity of 5 million sets. This enables delivery of parts to major cities nationwide within 72 hours.Internationally, products hold CE, UL, and IEC certifications, serving over 20 countries and regions including Europe, North America, and Southeast Asia. The company supplies global motor manufacturers such as Siemens and ABB, with overseas sales in 2024 growing by 351% year-on-year.

In terms of technological advancement, Xima Motor Components will focus on achieving higher power density through deep integration with AI: On one hand, developing ultra-thin (0.18mm) high-magnetic-flux silicon steel sheet cores and integrated winding assemblies will boost motor power density by over 20%, meeting the demands for miniaturized, high-power motors;On the other hand, it will introduce AI-powered intelligent monitoring accessories. By training fault prediction models with massive operational data, these accessories achieve over 95% accuracy in predicting motor failures. They provide early warnings—1 to 3 months in advance—for potential issues like bearing wear and winding aging, further reducing maintenance costs.

In terms of application expansion, beyond traditional industries, new energy vehicles, and wind power sectors, Xima Motor Components will extend into emerging applications such as backup motors for energy storage power stations, auxiliary motors for hydrogen fuel cell vehicles, and submersible motors for marine engineering. For instance, for backup motors in energy storage power stations, we are developing specialized sealing components resistant to high humidity and corrosion. For auxiliary motors in hydrogen fuel cell vehicles, we are creating dedicated bearing assemblies featuring low friction and high insulation, comprehensively meeting diverse market demands.

Interested in learning about Xima motor parts' tailored solutions for your specific industry? Or need to obtain product technical specifications manuals or request sample trials? Feel free to reach out anytime. We'll provide customized motor parts solutions to help your equipment achieve efficient, intelligent, and low-carbon operation!

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206