Article Catalog[Hidden]

- Sima Motor Slip Rings: Precision Rotary Connection Solutions for Efficient Energy and Signal Transmission

- I. Product Overview: Core Components of the Rotary Connection System

- II. Core technology features and performance advantages

- III. Application Areas and Industry Solutions

- IV. Technical Parameters and Specifications

- V. Selection and Installation Guide

- VI. Core Advantages of Xima Slip Rings

- VII. Conclusion

Simo motorsSlip Rings: Precision Rotary Connection Solutions for Efficient Energy and Signal Transmission

I. Product Overview: Core Components of the Rotary Connection System

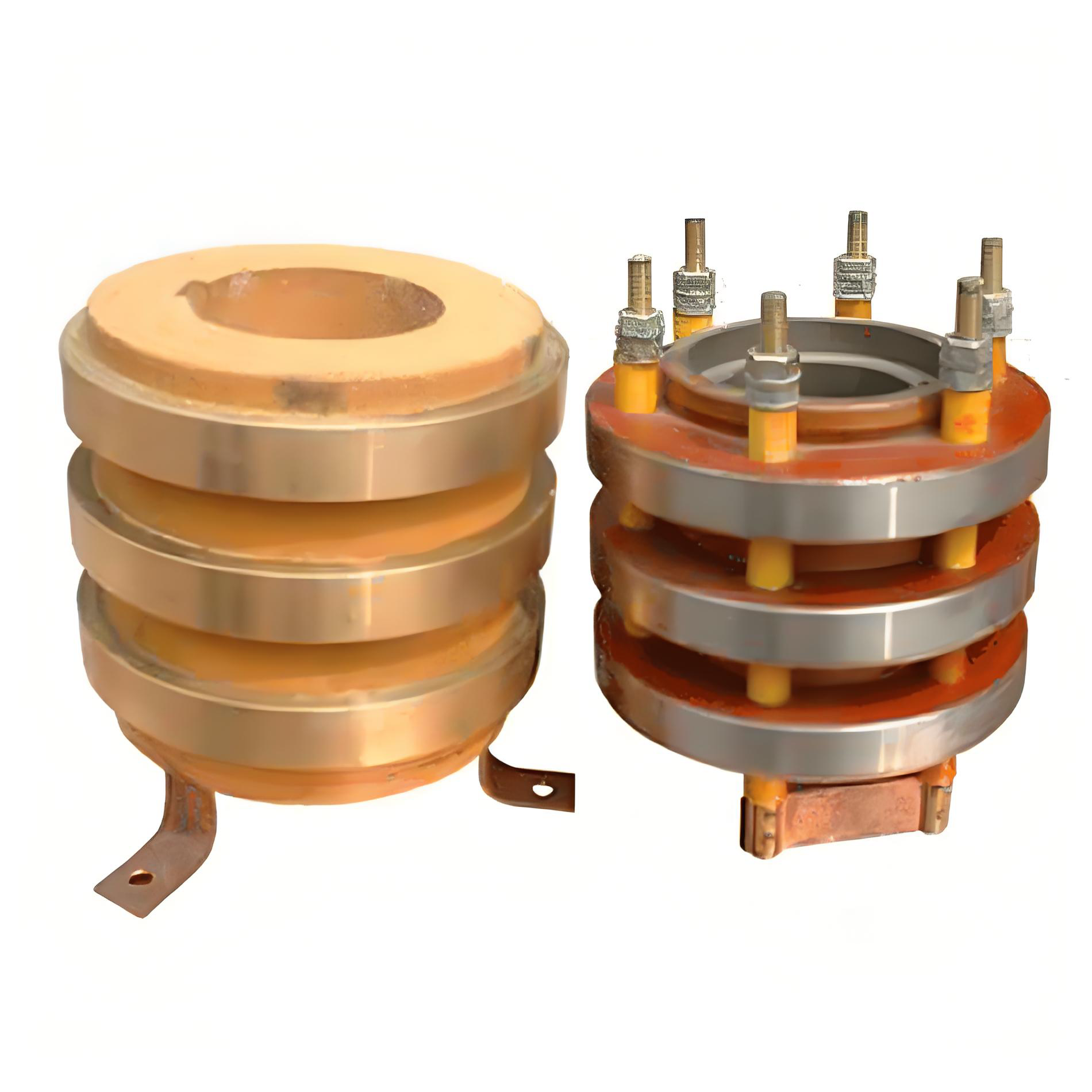

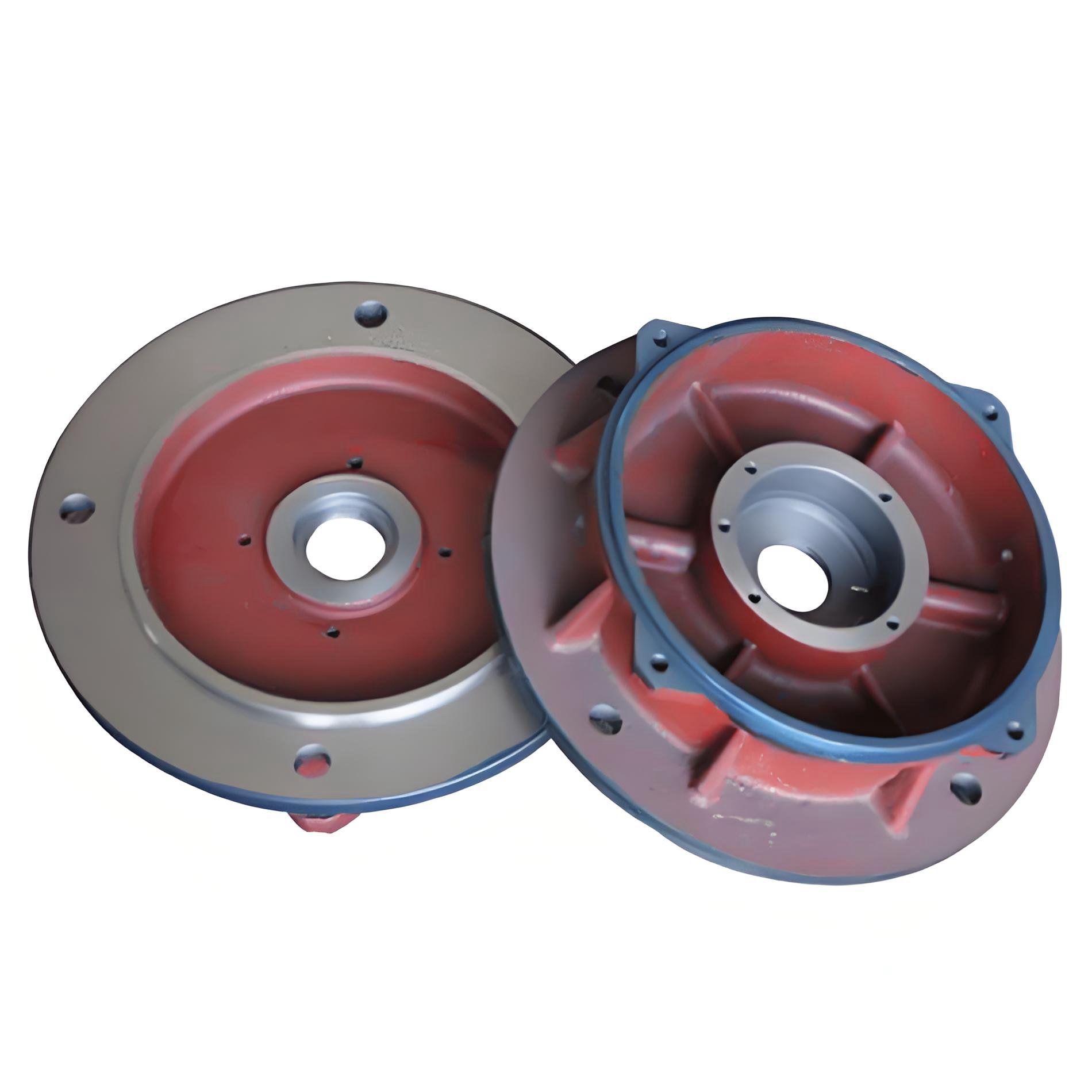

Simo Motor Slip Rings(also known as slip rings or rotating electrical interfaces) are specifically designed for various rotating electromechanical equipment.Precision Electrical Transmission ComponentsAs the interface between the rotating structure and the fixed structure of the equipment,Critical Energy and Signal Transmission BridgeXima slip rings adoptAdvanced electrical contact technology和Premium Materials and CraftsmanshipEnsure stable transmission of power, data signals, and various control commands during continuous rotation.。

Simar slip rings are widely used inHeavy industrial equipment、Precision instruments和High-end electromechanical systemsIn it, with itsExceptional electrical conductivity、Stable rotary contact和Long life designServing as an indispensable core component in motor systems, our products are manufactured in strict compliance with the ISO 9001 quality management system, ensuring every slip ring meets the rigorous demands of industrial applications.。

II. Core technology features and performance advantages

1. Precision Structures and Materials Science

Xima motor slip rings offer significant advantages in both structure and materials:

- Premium Material SelectionBased on application requirements, provideSteel slip rings、Copper slip ring及Special Alloy Slip RingSteel slip rings offer exceptional wear resistance and mechanical strength, making them suitable for high-speed synchronous motors; copper slip rings provide superior sliding characteristics and outstanding electrical conductivity.

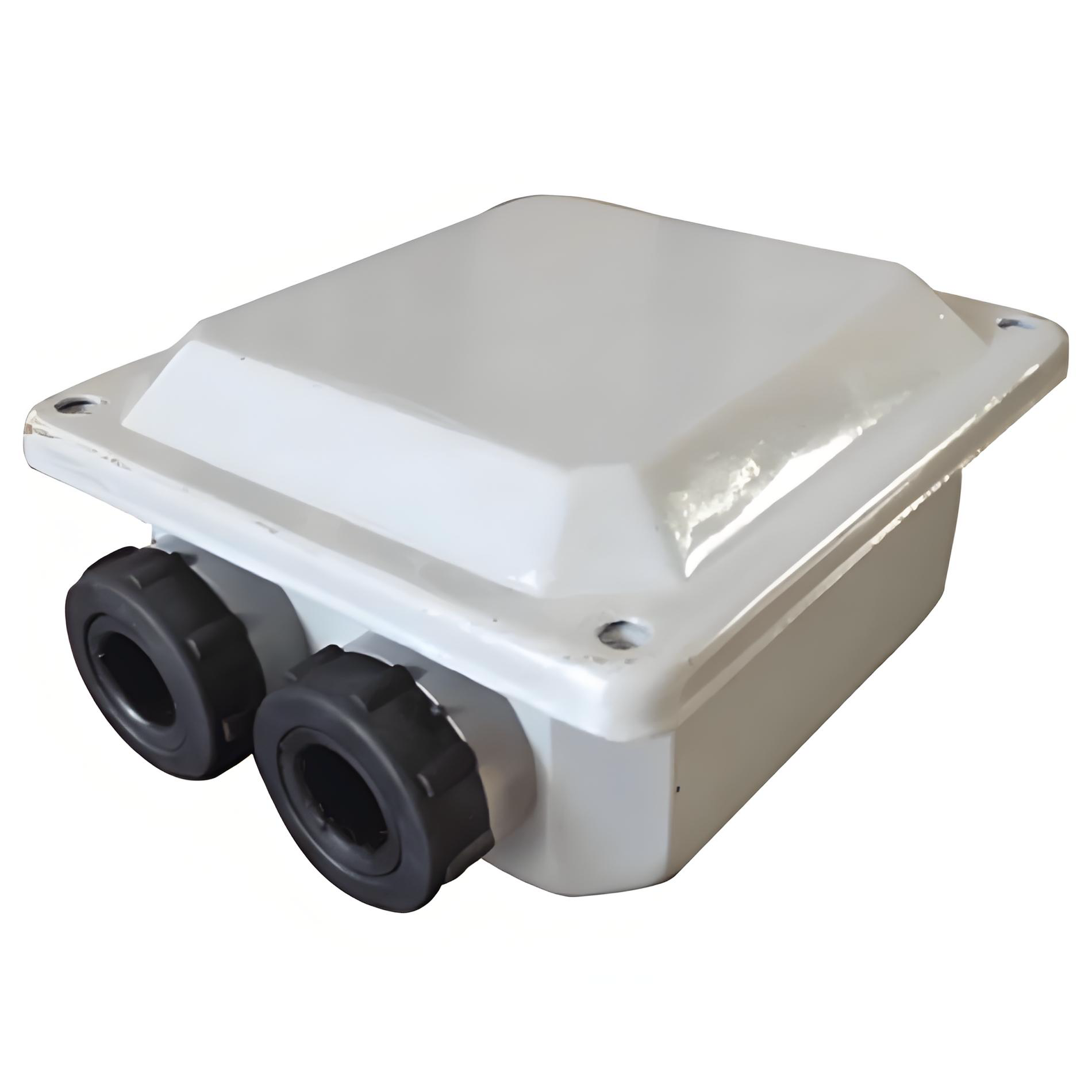

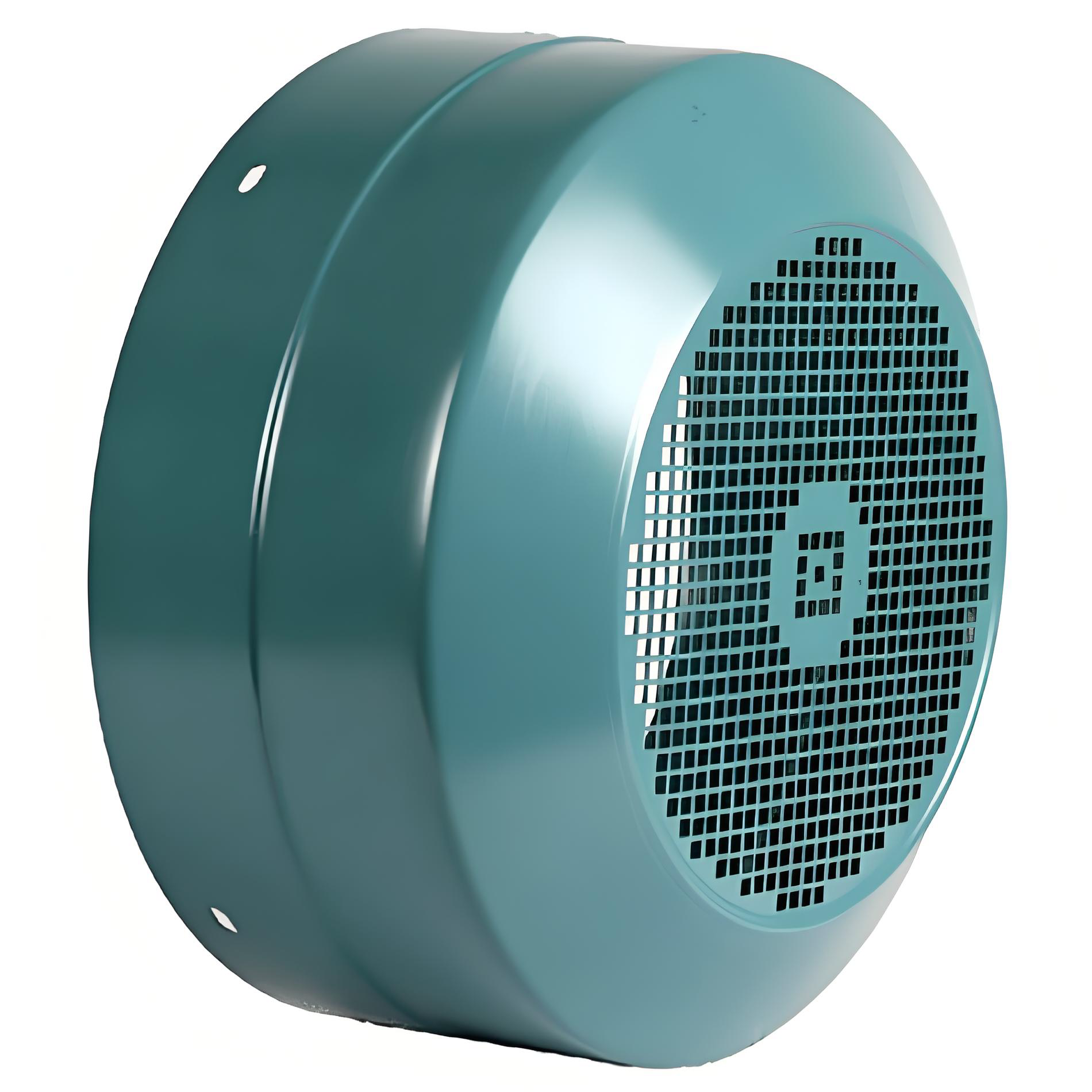

- Compact structural design: AdoptionModular Integrated DesignCompact structure, flexible installation, saving equipment space. The enclosure protection rating can reach up toIP65Can withstand harsh industrial environments such as high dust levels and humidity

- Precision Contact SystemRotating and stationary parts adoptPrecision contact structureEnsure stable electrical connections during high-speed rotation. Contact materials can be selected as needed.Precious Metals Portfolio(such as gold-to-gold contact), achieving extremely low contact resistance and exceptionally long service life

2. Superior Electrical and Mechanical Performance

Xima motor slip rings also deliver outstanding performance:

- High-Efficiency Energy TransmissionSupports high-current transmission, with the power section capable of reaching up to600AMeet the power supply requirements of high-power equipment. The rated voltage covers multiple industrial standards, including240 VACand higher voltage levels

- Multimode Signal Transmission: Can transmit simultaneouslyPower Supply、Control signal、Data bus(such as RS485, CAN bus, PROFIBUS, Ethernet, etc.) andSensor signalAchieve intelligent control of the rotating system

- Wide Temperature AdaptabilityOperating temperature range up to-30°C to +80°C(Special design can be extended to)-40°C to +80°C), adaptable to various harsh environmental conditions

- High-speed rotation capabilitySupports high-speed operation, with standard products capable of reaching300 revolutions per minuteSpecial design can achieve500 revolutions per minuteMeet the demands of high-speed equipment

3. Long service life and ease of maintenance

Xima Motor slip rings demonstrate outstanding performance in durability and maintenance:

- Extended design life: AdoptionOptimized contact design and premium materialswith a service life of up to30 million yuanThe above products are available.No maintenance required for 2 yearsQuality Commitment

- Low maintenance requirements:Brushless lifting and short-circuit deviceThe design significantly reduces maintenance frequency and complexity, lowering the total cost of ownership for the equipment.

- Self-Diagnostic Function: High-end models come equipped withCondition Monitoring InterfaceEnables real-time monitoring of slip ring operating status and provides early warnings for potential faults.

III. Application Areas and Industry Solutions

Xima motor slip rings play a critical role across numerous industrial sectors due to their exceptional performance:

1. Heavy Industrial Equipment Sector

- Mining and Metallurgical EquipmentPower transmission for large rotating equipment such as hoists, crushers, and rolling mills

- Power generation equipmentWind Turbine Yaw System, Hydropower Equipment Monitoring System

- Heavy machineryPort Cranes, Tower Cranes Slewing Systems

2. High-End Manufacturing and Automation

- Industrial robotEnergy and Signal Transmission at Robot Joint Rotation Points

- Automated Machining CenterElectrical Connections for Rotary Tables and Tool Magazines

- Precision instrumentsRotary interfaces for medical equipment and testing instruments

3. Special Application Environments

- AerospaceRotary Connections for Radar Systems and Navigation Equipment

- Shipbuilding and TransportationSignal transmission for marine radar and vehicle monitoring systems

- Harsh Environment ApplicationsReliable operation in dusty, high-humidity, and high-vibration environments

IV. Technical Parameters and Specifications

The primary technical specifications of the Xima motor slip ring are as follows:

| parameter category | Technical specifications and performance indicators |

|---|---|

| Electrical Parameters | Rated Voltage: Maximum 600 VAC/DC Rated current: Single circuit maximum 10A, power ring maximum 600A Insulation resistance: ≥1000 MΩ @ 500 VDC Contact resistance: <10 mΩ |

| Signal transmission | Supported signal types: Analog signals, digital signals, bus signals Maximum transmission rate: 1Gbps (Ethernet model) Signal Integration: Capable of mixed transmission of power and signals |

| Mechanical Parameters | Maximum speed: 300-500 rpm Protection Rating: IP54-IP65 Operating Temperature: -30°C to +80°C (Extendable to -40°C) Design life: ≥30 million revolutions |

| Physical Properties | Housing Material: Aluminum Alloy/Stainless Steel Contact material: Precious metal/alloy composite Wire Specifications: High-temperature silicone wire / Teflon wire |

V. Selection and Installation Guide

1. Selection Criteria

When selecting the appropriate Simma motor slip ring, the following key factors must be considered:

- Electrical demandDetermine the required transmissionTotal Power、voltage level、Current magnitude及Signal Type与Quantity

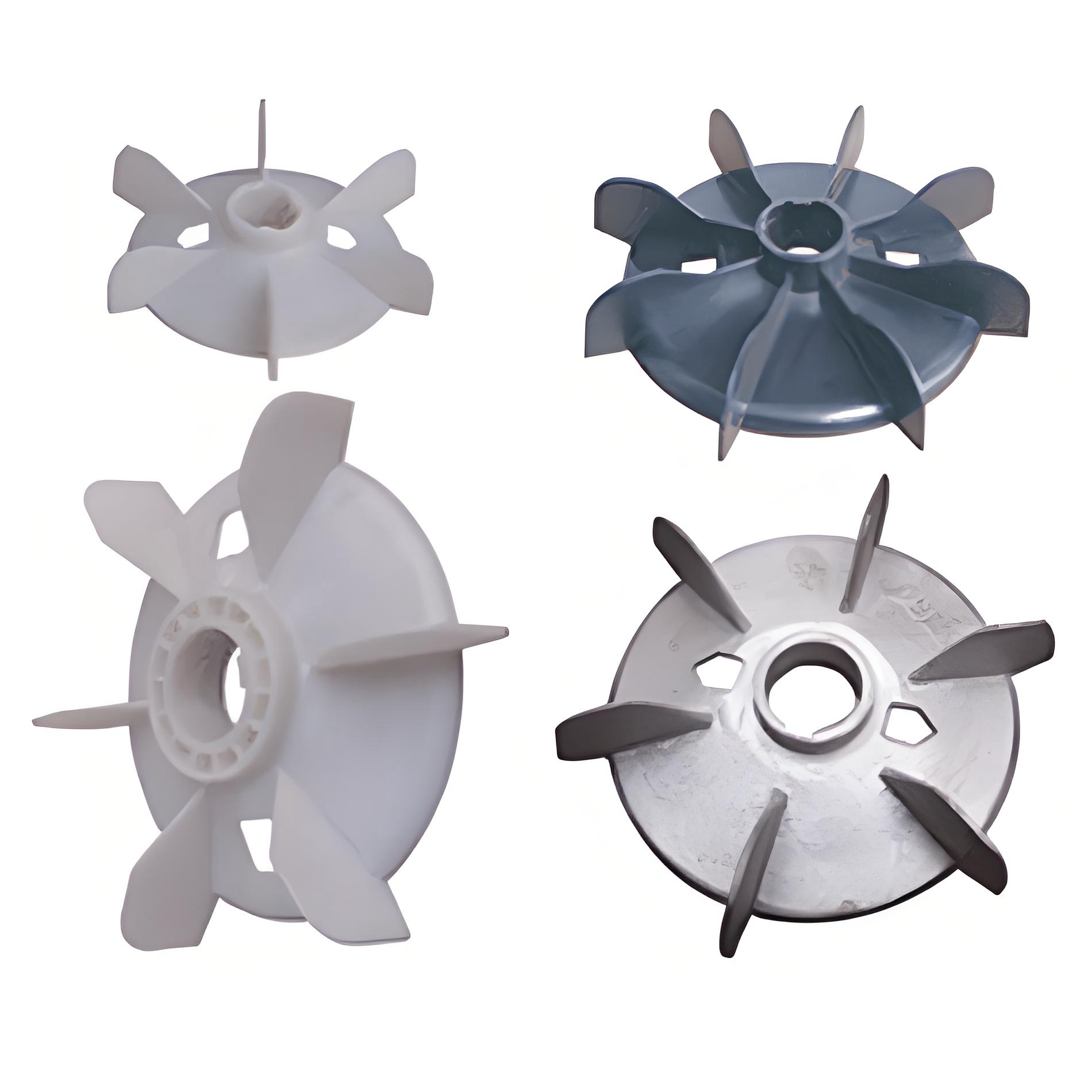

- Mechanical Constraint:: Considerationsmounting space、Shaft diameter、Weight Limit及Cooling method

- environmental conditions: AssessmentOperating Temperature、protection class、Vibration and shock及Corrosive environmentand other factors

- Rotational Speed RequirementsBased on the equipmentMaximum operating speedSelect slip ring products of the corresponding grade

2. Installation and Maintenance Guidelines

Proper installation and maintenance are key to ensuring the long-term stable operation of slip rings:

- Professional InstallationEnsure the slip ring aligns with the equipment's rotational center.Precise alignmentto avoid the influence of eccentric torque

- Wiring SpecificationsConnect wires correctly according to the labels, paying attention toSignal lines and power linesSeparation and Shielding

- Regular inspection: EstablishmentRegular Inspection SystemInspect the brush wear, contact surfaces, and connection status.

- Cleaning and MaintenanceRegularly clean contact surfaces and maintain the internal cleanliness of slip rings to prevent dust accumulation from affecting performance.

VI. Core Advantages of Xima Slip Rings

Xima motor slip rings hold a distinct competitive edge in the market:

- Technologically mature and reliableLeveraging Xima Motor's extensive experience in motor manufacturing, products undergo rigorous testing and validation.

- Strong customization capabilities:Can be provided according to customer requirementsCustomized Solutionsincluding special dimensions, specific interfaces, and hybrid transmission requirements

- Quality Assurance SystemFull-process quality control, with strict inspection standards from raw materials to finished products.

- Enhance service support: Provide fromTechnical Consultation、Selection Guide到Installation SupportFull-process service to ensure worry-free customer experience

VII. Conclusion

Xima motor slip rings serve as the key component in rotating electromechanical systems.Key transmission components, with itsExcellent technical performance、Reliable quality assurance和Wide range of applicationshas become an indispensable core component in the field of industrial equipment. As industrial automation and intelligence continue to advance, Xima Motors will remain committed to innovating and optimizing slip ring technology, providing global industrial customers with even moreAdvanced, reliable, and efficientRotary connection solutions.

Whether upgrading traditional industrial equipment or developing and manufacturing emerging smart machinery, choosing Xima Motor slip rings will significantly enhance your equipment's performance and reliability. Contact our technical team today for expert advice and tailored solutions for your specific application.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206