Article Catalog[Hidden]

- Xima Motor Junction Box: The Core Connection for Ensuring Safe Motor Operation

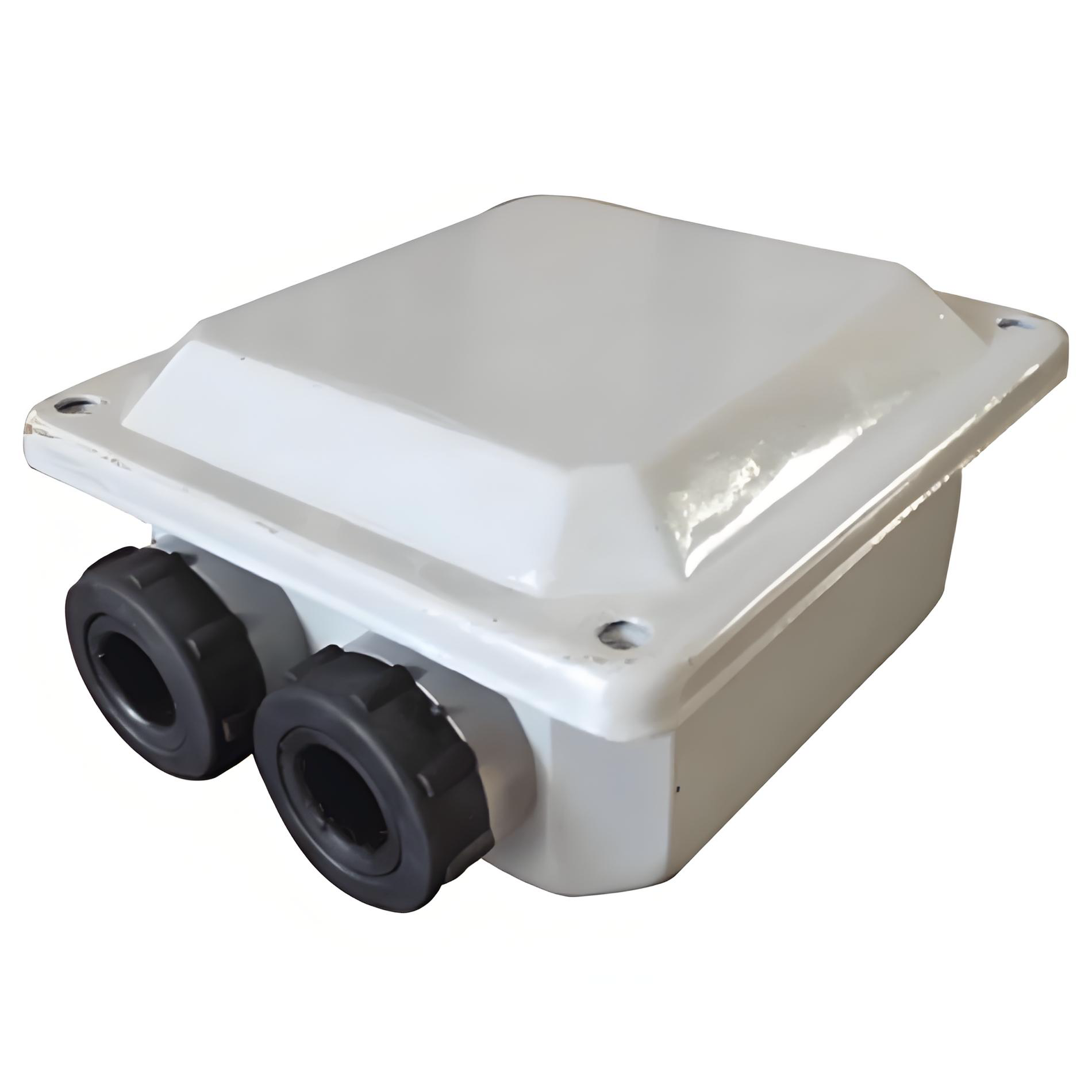

Simo motorsJunction Box: The Core Connector Ensuring Safe Motor Operation

Within the complex structure of an electric motor, the junction box serves asThe critical hub for power access and distributionIts performance and quality directly impact the stability and safety of the entire motor system.

Simo Motor Junction BoxIt is a crucial component of the electric motor, primarily responsible forPower cord introduction, internal connections, and securing, as well asProtect electrical contacts from corrosion caused by external environmentsAs the bridge connecting the motor to the external power source, the Xima motor junction box employsQuality materials和Precision Craftsmanshipmanufacture, possessingHigh protection rating, excellent insulation performance, reliable connections, and easy installation.Featuring characteristics such as high reliability, low resistance, and excellent electrical conductivity, these products are widely used in power connection systems for various industrial motors and motors operating in special environments.

I. Product Overview and Core Features

The Xima motor junction box is for electric motors.Core component of the power access systemTypically mounted on the outer side of the motor frame, it primarily bears the load.Power supply introduction, internal wiring, safety protectionand other critical functions. Through rational structural design and material selection, Xima motor junction boxes ensure reliable operation under diverse operating conditions.Safety and stabilityelectricity supply。

Core Functional Components

The Xima motor junction box comprises multiple precision components that form a complete connection system:

- Box Structure: AdoptionHigh-strength cast iron或Cast aluminum materialProvides robust mechanical protection and excellent heat dissipation performance.

- Sealing System: Equipped with professional sealing gaskets and cable connectors to ensure compliance withIP55 or higher protection ratingeffectively prevent dust, moisture, and other contaminants from entering

- Terminal block: ProvidedReliable electrical connection pointsUtilizing premium conductive materials to ensure low-resistance connections and excellent electrical continuity.

- Interior space:Featuring an optimized internal design, it deliversAmple wiring spaceto facilitate cable entry and wiring operations

II. Core technology features and performance advantages

The Xima motor junction box integratesInnovative Engineering Design与Strict quality controlIt offers significant advantages in performance:

1. Superior protective performance

- Multi-seal designThe input/output line interfaces adoptPrecision Sealing StructureThe box lid is fitted to the box body.Aging-resistant sealing gasketEffectively blocks the ingress of moisture, dust, and corrosive substances.

- High protection ratingStandard product protection rating reachesIP55Customizable for higher grades, suitable for harsh industrial environments such as damp or dusty conditions.

- High weather resistanceSpecial surface treatment processes enable junction boxes to adapt to-25°C to +40°CMaintain stable performance under varying ambient temperatures.

2. Reliable electrical performance

- Excellent insulating material: AdoptionHigh-Insulation Engineering Plastics或Metal housing with insulating liningDesign to ensure electrical safety

- Scientific Wiring LayoutInternal wiring terminals are arranged logically, with sufficient clearance provided.Adequate electrical clearance和Creepage distancePrevent arcing and short-circuit faults

- Grounding reliability: Equipped withDedicated Grounding TerminalEnsure the motor is reliably grounded to guarantee operator safety.

3. Easy installation and maintenance

- Reasonable internal spaceThe design fully considers the convenience of wiring and maintenance, providingSpacious operating area

- modular design:Some models useModular structurefor quick replacement and maintenance, minimizing downtime

- Flexible installation optionsOffers multiple mounting options to accommodate installation requirements for different motor models.

III. Technical Parameters and Specifications

Xima motor junction boxes cover a wide range of technical specifications to meet the needs of various application scenarios:

Main technical parameters

| parameter category | Technical specifications and performance indicators |

|---|---|

| Applicable Motor Power | 0.75 kW–1000 kW (depending on model) |

| protection class | IP55, IP56 (higher ratings available upon request) |

| Insulation class | Grade F, Grade H (depending on model) |

| rated voltage | 380V, 660V, 1140V (depending on motor specifications) |

| Rated current | Based on motor power configuration |

| Operating Ambient Temperature | -25°C to +40°C |

| Cable Interface Specifications | PG9-PG48, M20-M60 (multiple specifications available) |

| Box material | Cast iron, cast aluminum, engineering plastics (selected based on application environment) |

Product Line and Features

Xima Motor Junction Boxes offer multiple product series tailored to different application requirements:

- Standard Junction Box:Suitable for general industrial environments, providingBalanced performance和Economical pricingis the ideal choice for most electric motors

- Explosion-proof Junction Box: Has the followingHigher protection rating和Special explosion-proof designFor use in flammable and explosive hazardous areas

- Corrosion-Resistant Junction Box: AdoptionSpecial Surface Treatment和Corrosion-resistant materialsSuitable for corrosive environments such as chemical processing and marine applications

- High-Temperature Junction Box:UseHigh-temperature resistant materials和Special Heat Dissipation DesignSuitable for high-temperature applications such as metallurgy and boilers.

IV. Application Areas and Industry Solutions

Xima motor junction boxes are widely used across numerous industrial sectors due to their reliable performance and versatile designs:

1. Industrial Manufacturing Sector

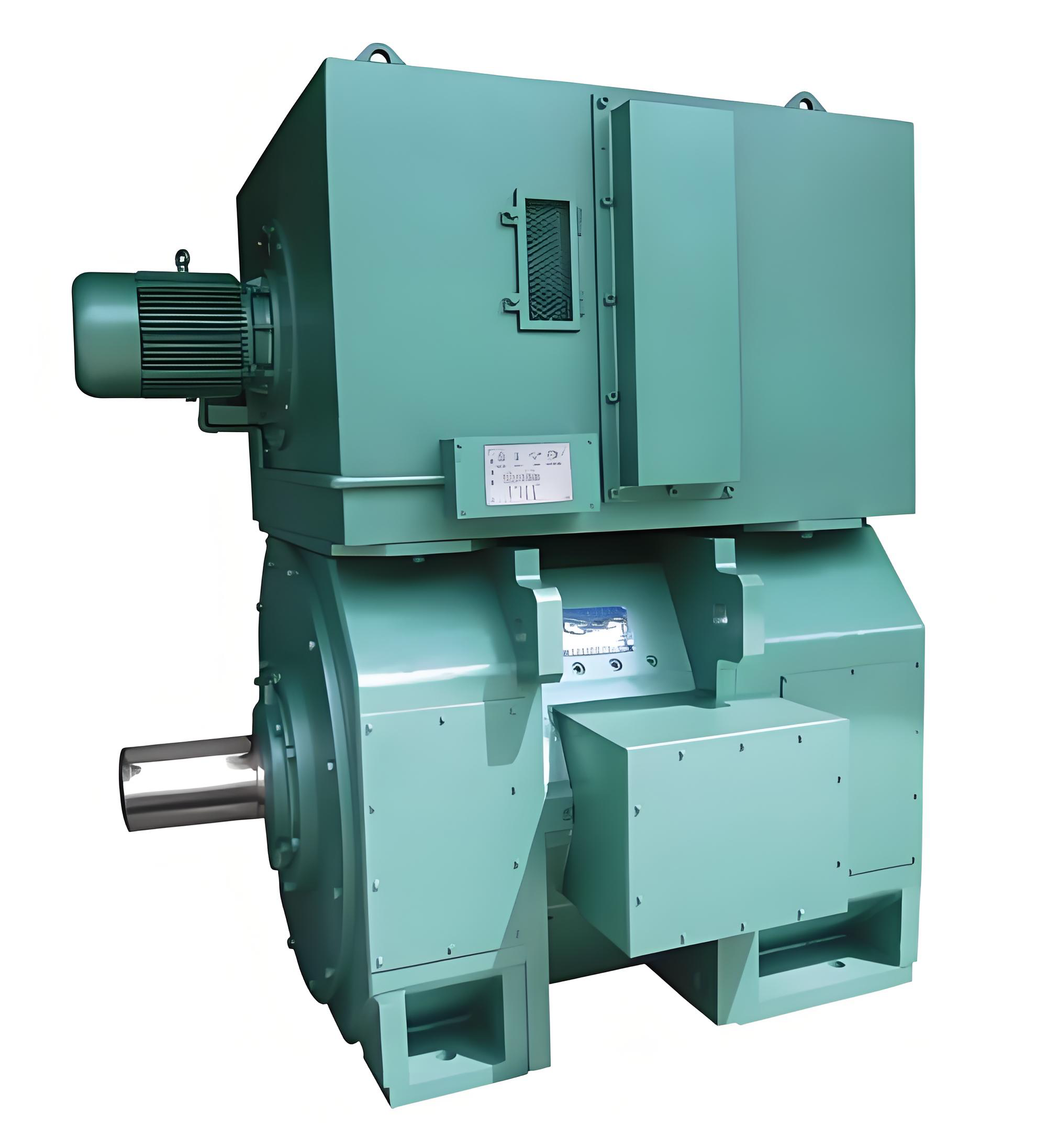

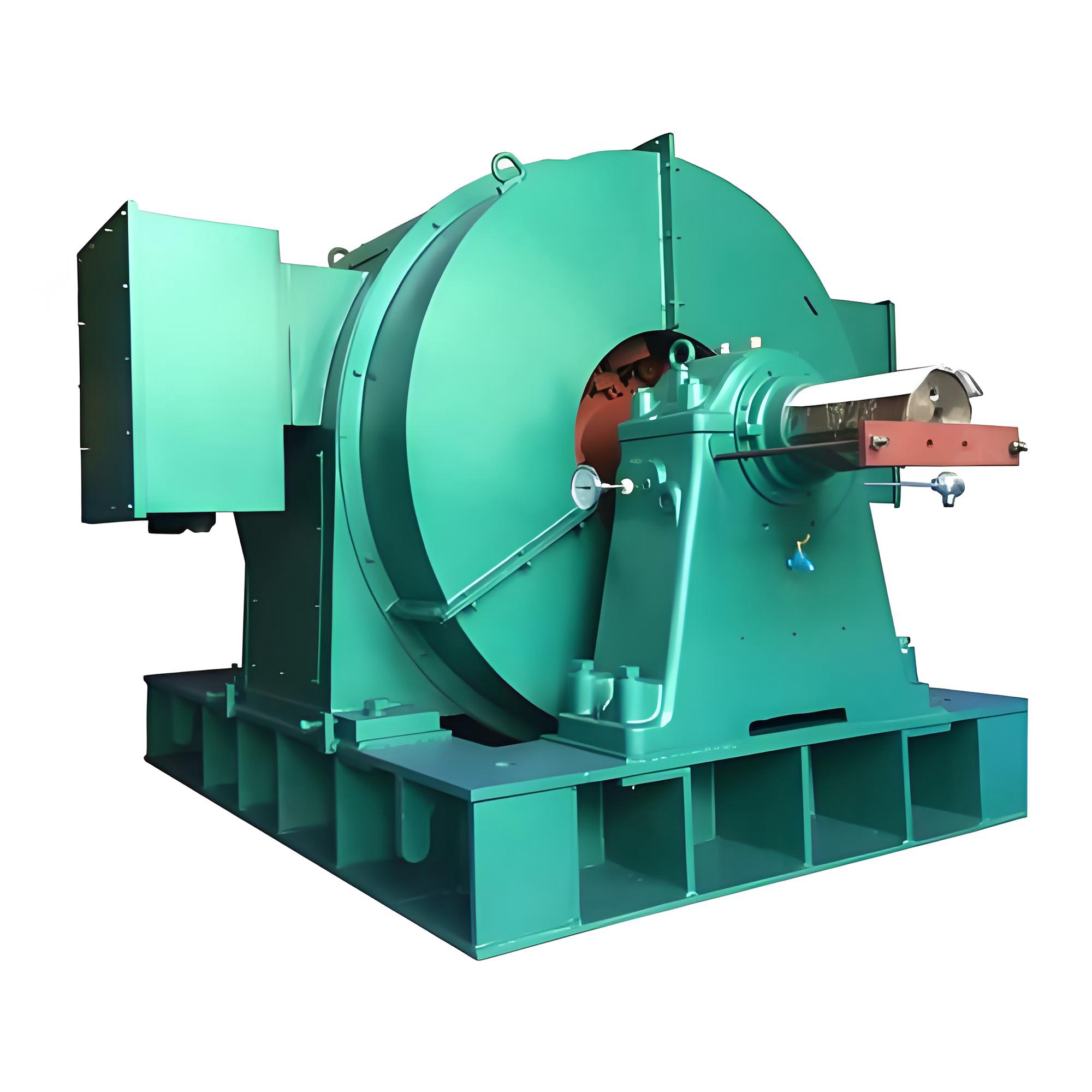

- Power industry: forBoiler Fan、Pump Motor及Generator setPower connections ensure the stable operation of electrical equipment.

- Metallurgical industry: Applied toRolling mill equipment、Smelting Fan及Transportation SystemMotor connection, withstanding high temperatures and high-dust environments

- Building materials industry: Applicable toCement Mill、Fan及Conveying equipmentThe motor wiring provides excellent protection performance.

2. General industrial and civil applications

- Fans and Pump EquipmentWidely used inCentrifugal fan、Axial-flow fan及Various types of pumpsMotor Wiring

- Industrial production equipmentFor variousmachine tool、Compressor、Conveying equipmentThe motor provides a reliable electrical connection.

- Water Treatment System: Applicable toWastewater Treatment、Water Supply SystemElectrical wiring requirements for motors in humid environments

3. Special Environment Applications

- Hazardous locations: forChemical Plant、Underground mineLocations requiring explosion-proof measures

- High-humidity environment: Applied toUnderground Engineering、Offshore platformIn humid environments, it offers outstanding corrosion resistance.

- Outdoor Applications: Applicable toOutdoor-installed motor equipmentProtects against wind, rain, and UV rays

V. Selection and Installation Guide

1. Selection Criteria

Selecting the appropriate Xima motor junction box requires comprehensive consideration of the following factors:

- Motor ParametersAccording to the motor'smodel number、power (output)、Rated Voltage and CurrentSelect the appropriate junction box specifications

- Operating Environment:: Considerationsenvironmental temperature、humidity level、Dust concentration及Corrosive Substance ContentTo determine the appropriate material and level of protection

- Cable Specifications: Based onPower cord size and quantitySelect the appropriate interface specifications and internal space

- special requirementConsider whether it is necessaryExplosion-proof、High-temperature resistant或corrosion resistanceSpecial properties

2. Installation Notes

Proper installation is the foundation for ensuring the junction box functions correctly:

- Sealing treatmentDuring installation, ensure thatPlace the gasket flat.,Secure the box lid evenly.achieve the required protection rating

- Cable entry:UseAppropriate cable connectorsEnsure reliable sealing at cable entry points to prevent moisture and dust ingress.

- Wiring qualityWiring should beSolid and dependable,No exposed conductorsMaintain adequate electrical clearance and creepage distance.

- Grounding SafetyEnsureGround wire reliably connectedEnsure personal safety

VI. Maintenance and Troubleshooting

1. Periodic inspection and maintenance

Maintenance of the Xima motor junction box is relatively straightforward and primarily includes:

- Regular inspection: Regularly inspect junction boxesSealing Condition,Is the cable joint loose?,Are there any abnormalities inside?

- Cleaning and MaintenanceRegularly clean the surface of the junction box.Dust and greaseEnsure adequate heat dissipation.

- Seal Replacement: Regular inspectionsCondition of seal gasket agingReplace promptly when necessary to maintain protective performance.

2. Common Troubleshooting

Common Issues and Solutions for Junction Box Usage:

- Seal failure: Typically bySeal aging或Improper installationRequire replacement of the gasket or reinstallation.

- Loose wiring: Due toVibration或Thermal expansion and contractionThis requires periodic inspection and retightening.

- Insulation degradation: Typically byDamp或Dust accumulationCaused by, requiring cleaning and drying treatment

VII. Service and Support

Xima Electric provides comprehensive technical support and service guarantees for junction box products:

- Specialized technical consulting:Provide professional consulting services for product selection and application solutions

- Customized Services: Provided according to customer's special needsPersonalized Design and Manufacturing Servicesmeet specific application requirements

- Perfect after-sales protection: Provide quality assurance and after-sales service to ensure worry-free use by customers

- Adequate inventory guaranteeStandard motors are available.Large quantities of junction boxes and other accessories in stockMeet customers' urgent needs

The Xima motor junction box, with itsScientific design、Premium materials和Precision manufacturing processbecome various types of electric motorsIdeal Power Connection SolutionsWhether it beGeneral industrial applicationsorHarsh special environmentsSimar motor junction boxes can all provideReliable performance和Long service life。

Choosing Xima Motor Junction Boxes means choosingReliable connection assurance和Long-lasting operational performanceWe look forward to working with you to provide the optimal power connection solutions for your equipment.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206