Simar Synchronous Motors: High-Performance, High-Efficiency Precision Power Source

Date: 2023-08-21 Categories: Company News Views: 905

Article Catalog[Hidden]

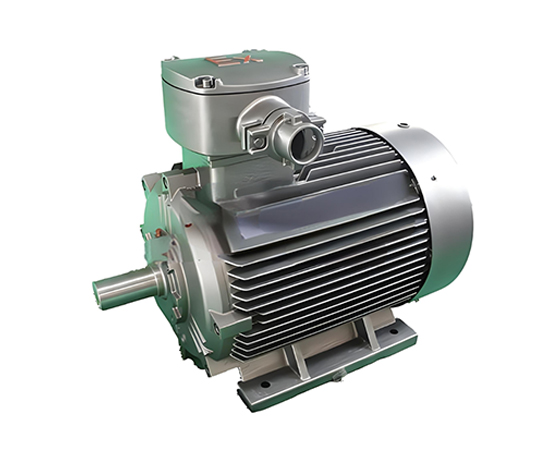

Simo synchronous motor:High-performance, high-efficiency precision power source

🌟 Introduction: The “Precision Controller” in the Industrial Sector”

A synchronous motor is an AC motor that maintains a strict synchronous relationship between rotor speed and power supply frequency during steady-state operation. With its high power factor, high efficiency, and precise speed control capabilities, the Xima synchronous motor serves as a core power source and “precision controller” in industrial applications demanding high performance, high stability, and accurate speed regulation.

🚀 Core Advantages and Technical Features

The Simar synchronous motor stands out among numerous motor types due to its unique design and technological advantages:

- High Efficiency and Energy Saving: Synchronous motors exhibit no slip losses, resulting in higher efficiency compared to asynchronous motors. Particularly in large-scale industrial applications, this high efficiency significantly reduces operating costs and energy consumption, aligning with green manufacturing trends.

- High Power Factor: Synchronous motors can improve the power factor of the power grid by adjusting the excitation current and can even operate at a leading power factor. This is of great significance for enhancing grid quality and reducing the apparent power demand of the power supply system.

- Precise speed control: The rotational speed of synchronous motors is strictly synchronized with the power supply frequency, meaning their speed control is exceptionally precise and stable, unaffected by load fluctuations.

- Structural Diversity: Synchronous motors include permanent magnet synchronous motors (PMSM) and separately excited synchronous motors, among others. Permanent magnet synchronous motors offer advantages such as high power density, compact size, and light weight.

- Powerful dynamic response: Synchronous motors deliver outstanding dynamic response and transient performance, especially when paired with modern variable frequency drives and high-performance control systems.

🏭 Typical Application Areas

Simultaneous synchronous motors are widely used in the following industrial sectors due to their high precision and high performance:

- Large compressors and water pumps: Designed to drive large compressors, water pumps, and fans, particularly in applications requiring long-term stable operation and high efficiency.

- Metallurgical Industry: For heavy-duty equipment requiring high torque and precise speed control, such as rolling mills and hoists.

- Power Systems: Used as generators and synchronous condensers for power generation and improving the power factor of the grid.

- New Energy and Servo Systems: Permanent magnet synchronous motors are widely used in new energy vehicles, robotics, CNC machine tools, and other fields demanding extremely high positioning accuracy and dynamic performance.

💡 Selection and Maintenance Recommendations

To ensure optimal performance of the Xima synchronous motor, the following aspects must be observed:

- Control System Matching: Synchronous motors typically require high-performance variable frequency drives or dedicated synchronous controllers for drive and control. During selection, ensure perfect compatibility between the motor and the control system.

- Thermal Management: High-power-density and high-performance motors have demanding thermal management requirements. Ensure their cooling systems (such as forced ventilation or water cooling) operate properly to prevent overheating that could compromise insulation lifespan.

- Insulation Protection: Regularly inspect and maintain the insulation performance of motor windings, especially for permanent magnet synchronous motors, whose insulation materials must withstand high-frequency voltage surges.

The Simul motor represents a key technology for future high-end manufacturing and energy conservation. It provides stable, efficient, and precise power solutions for industrial applications.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206