Motor Carbon Brush_High-performance industrial motor parts factory direct supply

Date: 2023-08-20 Categories: Industry News Views: 885

Article Catalog[Hidden]

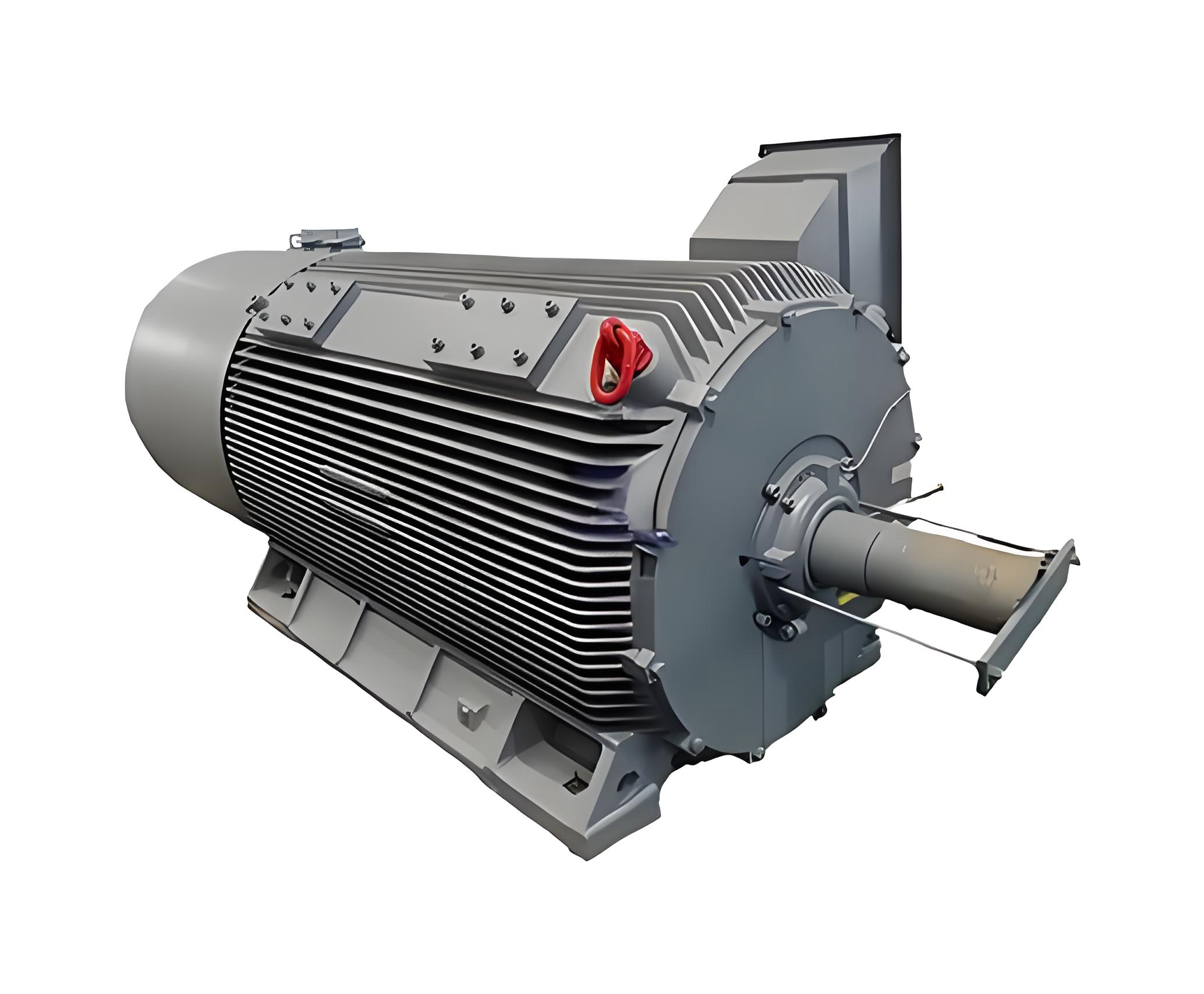

I. Product Overview

Motor Carbon BrushesIs it communication orDC motorA critical consumable component used for Electric Power Transmission, Commutation, and Motor StabilityHigh-quality carbon brushes reduce wear, minimize sparking, enhance motor efficiency, and extend motor lifespan.

Applicable toHigh voltage motorsLow-voltage motors, high-power motors, DC motors,Variable Frequency Motor及Explosion-proof motorsWidely used in mining, metallurgy, cement, power generation, fans and pumps, and industrial automation equipment.

II. Core Performance and Advantages

- High electrical conductivity:Made from premium graphite or copper-graphite materials to ensure stable electrical conductivity.

- High wear resistanceLong-life design, reducing replacement frequency

- Low-spark designProtect the commutator to reduce the risk of motor failure.

- Highly adaptable:Suitable for high and low voltage motors of various specifications and models

- Strong customization capabilitiesNon-standard sizes, shapes, and materials can be customized according to customer requirements.

III. Main Technical Parameters

| Parameter Item | Technical Scope |

|---|---|

| Material | Graphite, copper-graphite, alloy graphite |

| Current Carrying Capacity | 1A to 500A (customizable) |

| Operating Temperature | -20°C to +150°C |

| Motor Adapter | High-voltage motors, low-voltage motors, DC motors, variable-frequency motors, explosion-proof motors |

| lifespan | ≥1000 hours (customizable based on operating conditions) |

IV. Typical Application Industries

- MineBall mill, crusher, elevator

- MetallurgyRolling mills, electric furnace auxiliary equipment

- Cement/Building MaterialsRotary kiln, roller press, conveying equipment

- Fans/Pumps/PowerRecirculating water systems, wastewater treatment plants

- Industrial AutomationProduction line drives, mixers, compressors

V. Services and Support

- Direct from manufacturer, full range of models, reliable delivery times

- Customization available for non-standard sizes and materials

- Nationwide installation, commissioning, and after-sales technical support

- Provide samples and technical documentation to support engineering projects and bidding processes.

- We provide motor carbon brush matching solutions and usage guidance.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206