Simo High Voltage Motors: Model Parameters, Structural Characteristics and Industry Application Guidelines

Date: 2023-08-21 Categories: Company News Views: 970

Article Catalog[Hidden]

I. Introduction: XimaHigh voltage motorsWhy is it widely used in large factories?

Within the domestic industrial sector,Simo High Voltage MotorsDue to their high efficiency, stability, heavy-duty capability, and simple maintenance, high-voltage motors are widely used in large-scale equipment such as steel mills, cement plants, petrochemical facilities, power stations, mines, fans, and pumps. As enterprises increasingly demand higher equipment reliability and energy efficiency ratings, high-voltage motors are becoming increasingly vital in production lines.

This article will systematically analyze the professional value of Xima high-voltage motors from the perspectives of principles, structure, parameters, applications, and selection.

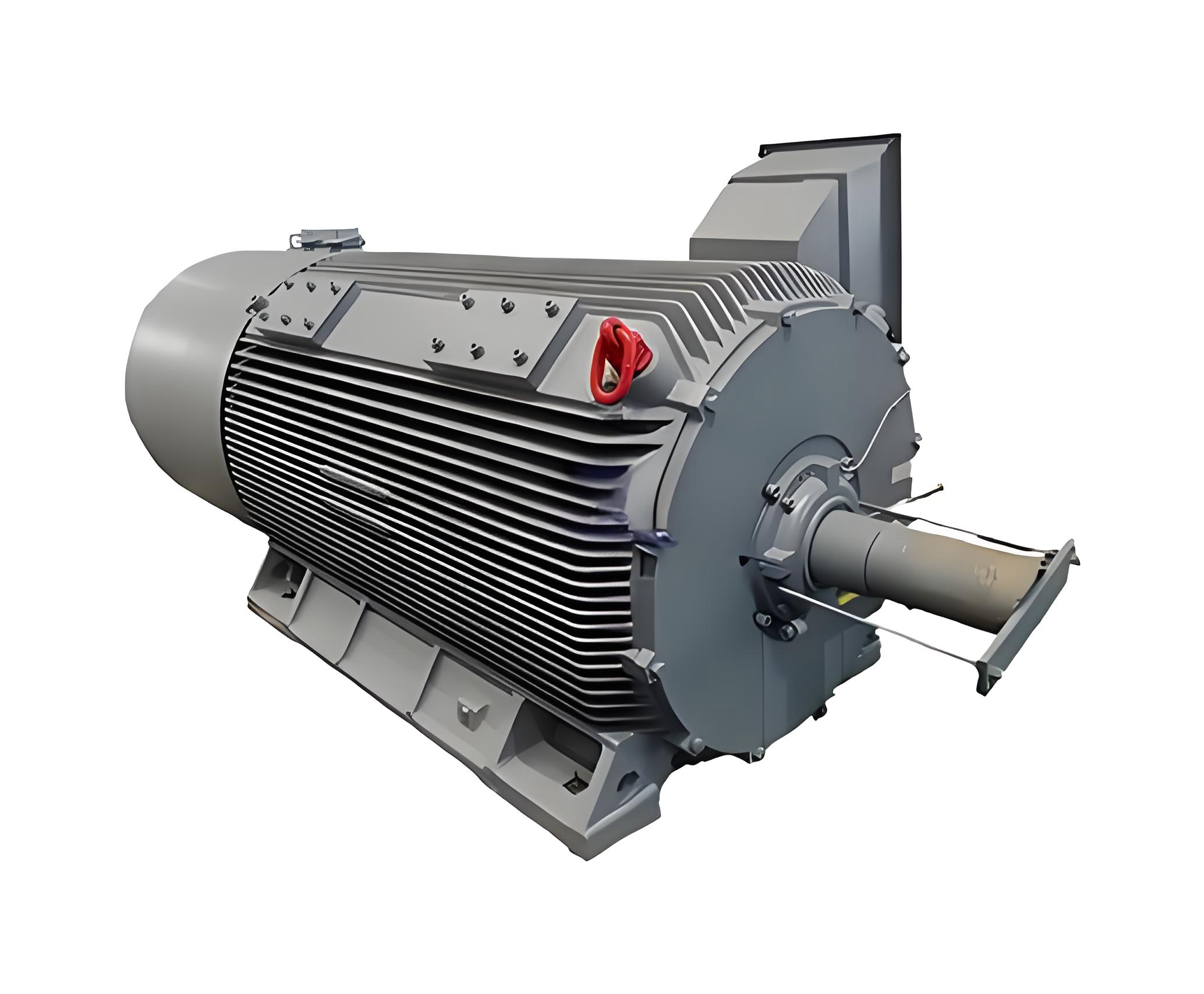

II. What Is a Simar High-Voltage Motor? Analysis of Its Working Principle and Structure

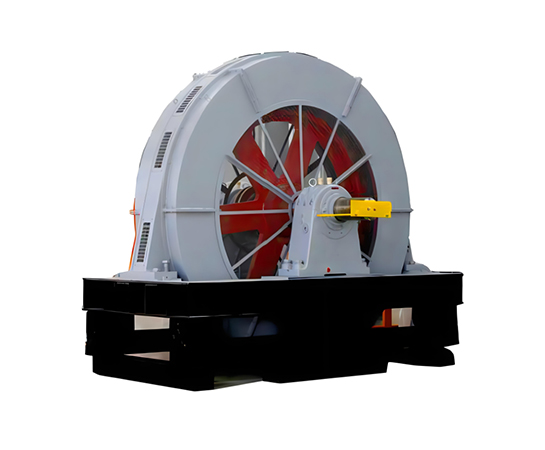

Simo High Voltage MotorsRefers to a rated voltage that is generally 3kV, 6kV, 10kV High-voltage operating motors, which are high-power industrial motors.

It is primarily composed of the following core structures:

- Stator sectionHigh-voltage coils utilize F-class or H-class insulation systems.

- Rotor sectionCopper strips or cast aluminum construction, high mechanical strength

- BaseCast iron or steel plate welded construction, impact-resistant

- Bearing SystemRolling bearings or sliding bearings, suitable for heavy-duty applications

- Cooling methodIC411, IC416, IC611, IC81W, etc.

- Startup MethodCompatible with high-voltage soft starters, variable frequency drives, and voltage-reduction starter cabinets.

Working Principle:

Its core principle involves a three-phase alternating current generating a rotating magnetic field in the stator, which drives the rotor to rotate, thereby providing continuous and stable mechanical power.

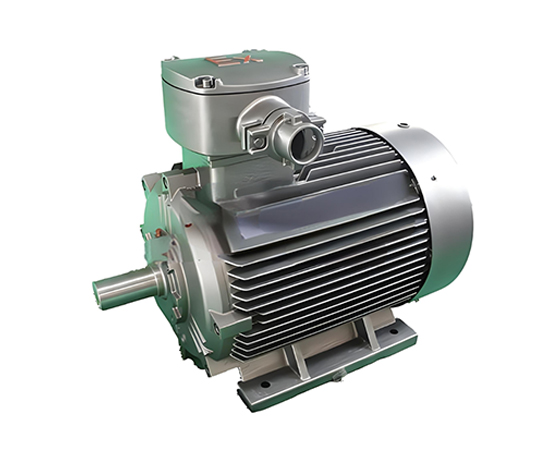

III. Core Features and Advantages of Xima High-Voltage Motors

1. Powerful output, suitable for large machinery

The power range is typically between 200 kW–20,000 kWIt can meet the power requirements of large-scale fans, pumps, compressors, mills, and other host machines.

2. High Efficiency and Energy-Saving Performance

- High-Efficiency Motor Design

- Reduced operating costs

- Meets national energy efficiency standards (YE3, YE4)

3. Low temperature rise, strong capability for heavy-load operation

The windings and core feature an optimized design to reduce losses and enhance high-temperature resistance.

4. Sturdy construction, long service life

The base features high rigidity and strong resistance to mechanical impact and vibration, making it suitable for harsh environments such as mines and steel mills.

5. Highly adaptable

Supports customization of rotational speed, mounting methods, cooling methods, bearings, insulation classes, and more, compatible with various industrial equipment.

IV. Application Areas: Which operating conditions are most suitable for Xima high-voltage motors?

Based on domestic industrial demand, Xima high-voltage motors are commonly used in:

✔ Steel Industry

Blower, induced draft fan, hoist, rolling mill main motor

✔ Cement Industry

Raw Material Mill, Cement Mill, Kiln Tail Fan

✔ Power industry

Circulating water pump, dust removal fan, boiler fan

✔ Chemical and Petrochemical Engineering

Compressor, conveying fan, vacuum pump

✔ Mining industry

Crusher, conveyor belt, grinding system

✔ Municipal and Water Treatment

Large-scale pump stations, motor-driven pump sets

V. Xima High-Voltage Motor Selection Guide (Engineer Recommendations)

When selecting high-voltage motors, the following parameters should be prioritized:

1. Power (kW) and rated voltage

Ensure compatibility with the host power supply and high-voltage grid.

2. Rotational Speed (2/4/6/8-pole)

Different pole numbers correspond to different rotational speeds, which must be selected based on mechanical load and operating conditions.

3. Cooling Method

Common cooling methods include:

- IC411Self-Fan Cooling

- IC416Outside Fan Cool

- IC611 / IC81WWater-cooled and air-cooled hybrid design, suitable for heavy-duty and high-temperature environments

4. Startup Method

- Variable Frequency Drive Start

- High-Voltage Solid-State Soft Starter

- Self-coupled buck start

Select based on equipment inertia and grid capacity.

5. Protection Rating and Mounting Method

Common:

- IP54 / IP55 / IP65

- IMB3 / IMV1

Suitable for different operating conditions.

VI. Why Do Numerous Enterprises Nationwide Choose Xima High-Voltage Motors?

1. Technologically mature and highly stable

Large state-owned enterprise background, mature standardized processes.

2. Complete range of models, customizable to meet your needs

Supports deep customization of parameters including power rating, frame size, cooling, and bearings.

3. Reliable quality, suitable for various harsh operating conditions

Long service life, simple maintenance, and stable performance.

4. Strong supporting capabilities

We offer one-stop solutions for:

Frequency converters, soft starters, couplings, motor control cabinets, etc.

VII. Frequently Asked Questions (FAQ)

1. What is the common voltage for Xima high-voltage motors?

3kV, 6kV, and 10kV are the mainstream models.

2. Can Xima high-voltage motors be used for variable frequency speed control?

Yes, a frequency-conversion-resistant insulation system must be selected.

3. Do you offer customization for non-standard specifications?

Support includes bearings, flanges, cooling, insulation class, mounting dimensions, etc.

4. What is the typical delivery time for high-voltage motors?

Standard models: 30–45 days. High-power or custom models: 45–60 days.

VIII. Conclusion: Professional high-voltage motor selection ensures greater stability and efficiency.

Xima high-voltage motors have become the vital power core for numerous heavy industrial sectors due to their stability, reliability, and broad adaptability. If you require model selection, technical solutions, or custom specifications, we recommend providing your operating parameters (power, speed, load, environment, etc.) to our professional engineers to ensure optimal configuration.

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206