Excerpt:

Xi'an Taifu Simo Z4 series DC motors have greater superiority than Z2 and Z3 series, which not only can be powered by DC unit power supply, but also more suitable for static rectifier power supply. It can be widely used in metallurgical industry rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, plastic extrusion machinery, etc.......

Article Catalog[Hidden]

- Xi'an Taifu Simo Z4 Series DC Motors: High-efficiency Industrial Drive Solutions

- Product Model Analysis: Accurately Identify Motor Specifications

- Product Technology Overview: Innovative Design Leads the Industry

- Advanced structural design: a solid foundation for superior performance

- Core Technology Advantage: Redefining DC Motor Performance Standards

- Intelligent Control System Integration

- Xi'an Simo Motor Quality Assurance System

- Professional Selection and Ordering Guide

- Recommended Application Scenarios

- concluding remarks

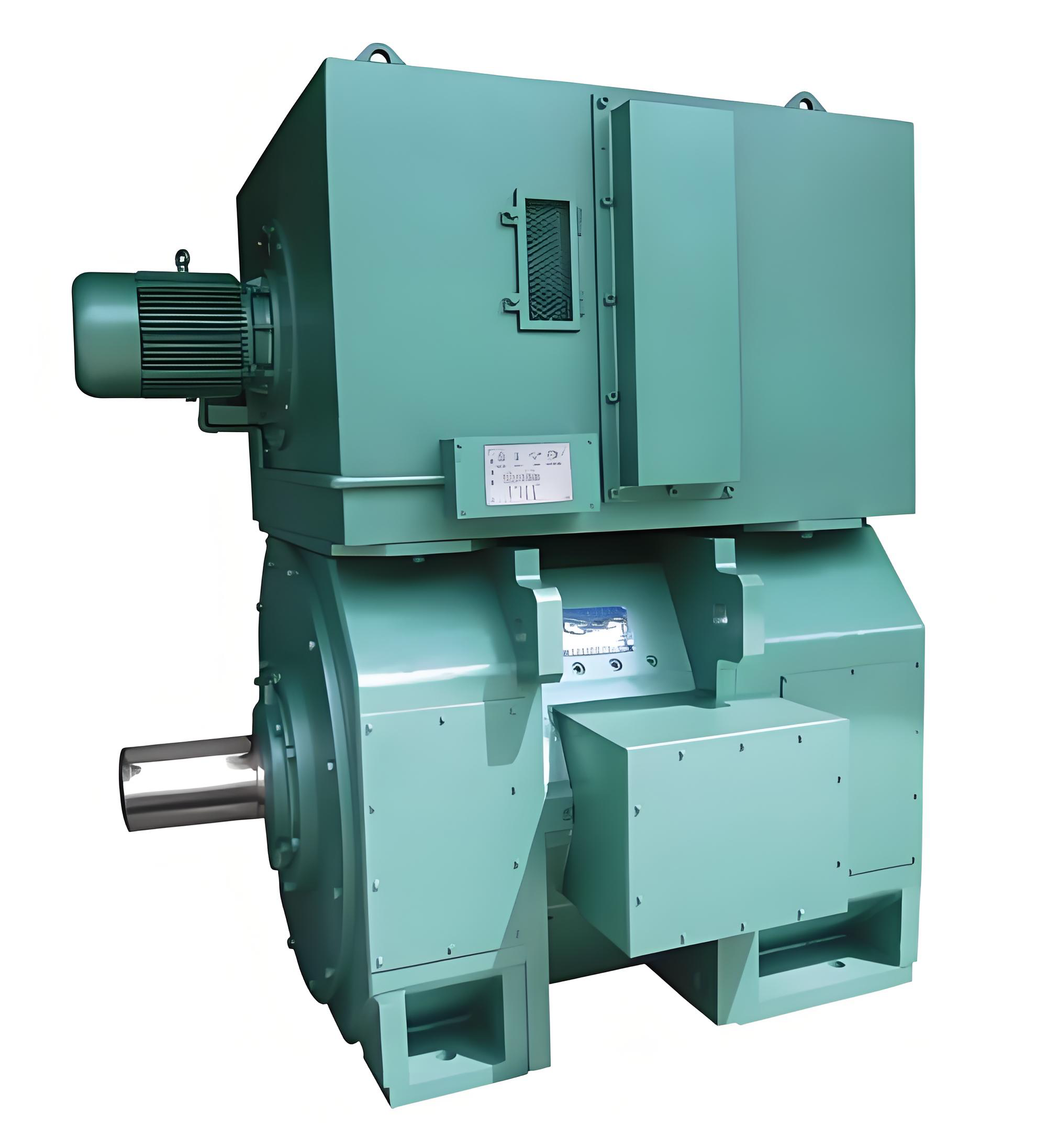

Xi'an Taifu Simo Z4 SeriesDC motor: High-performance industrial drive solutions

Adopting international advanced technology to provide precise and reliable DC power for modern industry

Xi'an Taifu Simo Z4 series DC motors areFourth generation DC motor technologyThe outstanding representative of the integratedAdvanced electromagnetic design与Innovative cooling system. This series of motors not only inherits the excellent characteristics of the traditional DC motors, but also in theDynamic Response Speed、Speed control accuracy和energy efficiency performanceIt has realized a major breakthrough in the field of modern industrial automation and has become the ideal choice of power.

Product Model Analysis: Accurately Identify Motor Specifications

Xi'an Taifu Simo Z4 series DC motors adopt systematic naming rules, taking Z4-280-11B as an example for detailed analysis:

Complete model structure:

- "Z" mark: DC motor category identification

- "4" series: Fourth generation DC motor product line

- "Size "280": Motor center height 280mm

- First "1": Core length serial number

- Second "1": Front end cap specifications (1 for short end caps, 2 for long end caps)

- "B" characteristics: Compensation Winding Configuration Identification

Special model description:

For model Z4-112/2-1:

- "First digit after "/": Number of motor poles

- second digit: Core length serial number

The naming system strictly followsInternational Electrotechnical Commission (IEC) standardsThe same time, it meets the requirements of theGB/T 4831 Method of Preparation of Electric Motor Product NumbersRequest.

Product Technology Overview: Innovative Design Leads the Industry

Technical standards and scope of specifications

Z4 series DC motors cover100~710mm center heightThe complete product line of the

- Center height 100~355mm: Small DC motors in accordance with JB/T6316-92 industry standard

- Center height 400~450mm: Standard Series Expansion Models

- Center height 500~710mm: New generation of medium-sized DC motors

Excellent technical characteristics

Compared to its predecessors, the Z2 and Z3 series, the Z4 series exhibits aSignificant technical advantages:

- Power supply adaptability: Perfect match between DC unit power supply and static rectifier power supply

- Dynamic performance: Smaller moment of inertia and greater ability to withstand load variations.

- control accuracySupport smooth speed regulation, automatic speed stabilization, sensitive and fast response

Core technical parameters

- power range: 1.5kW to 840kW

- rated speed: Nine standard sizes (3000-200r/min)

- Excitation method: Standard excitation, excitation voltage 180V

- Insulation class: Class F insulation system

- working environment: Altitude ≤1000m, ambient temperature ≤40℃.

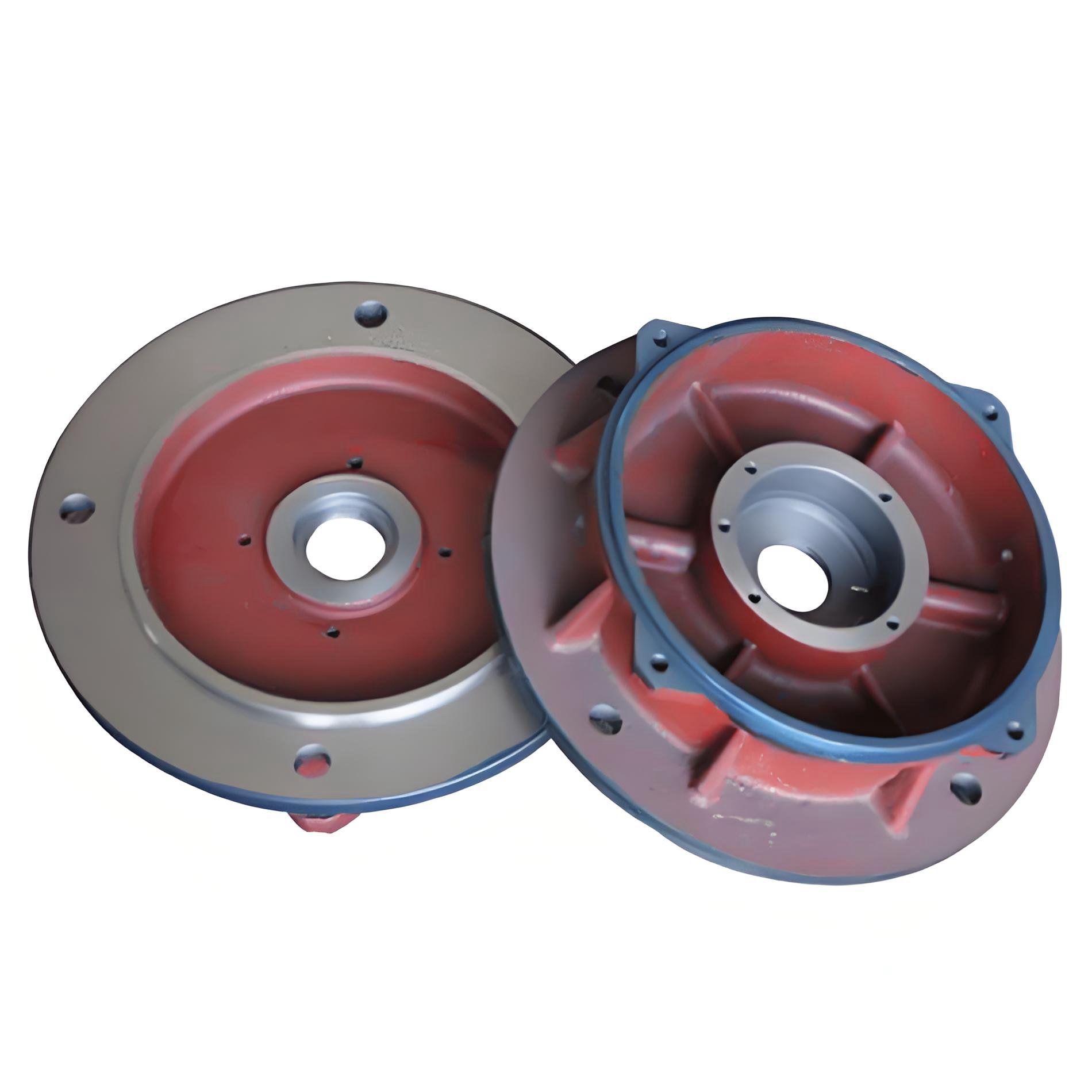

Advanced structural design: a solid foundation for superior performance

Innovative electromagnetic structure

Octagonal fully laminated stator design:

- Enhanced space utilization 15% or more

- Enhanced pulsating current tolerance

- Supports fast load change response

Winding configuration flexibility:

- Basic model without series excitation winding, support forward and reverse control

- Center height 315~450mm standard with compensation winding

- Supports customized versions with series excitation windings

Versatile cooling systems

The Z4 series offersFive advanced cooling solutions:

| Cooling method | Applicable environment | Characteristic Advantages |

|---|---|---|

| IC06 | Standard industrial environments | Self-contained blower for external ventilation |

| IC17 | Restricted ventilation space | Ducted air intake, louvered exhaust |

| IC37 | confined space | Dual Duct Ventilation System |

| IC611 | Highly dusty environments | Totally enclosed air-to-air cooling |

| ICW37A86 | high temperature environment | Totally enclosed air-water cooled |

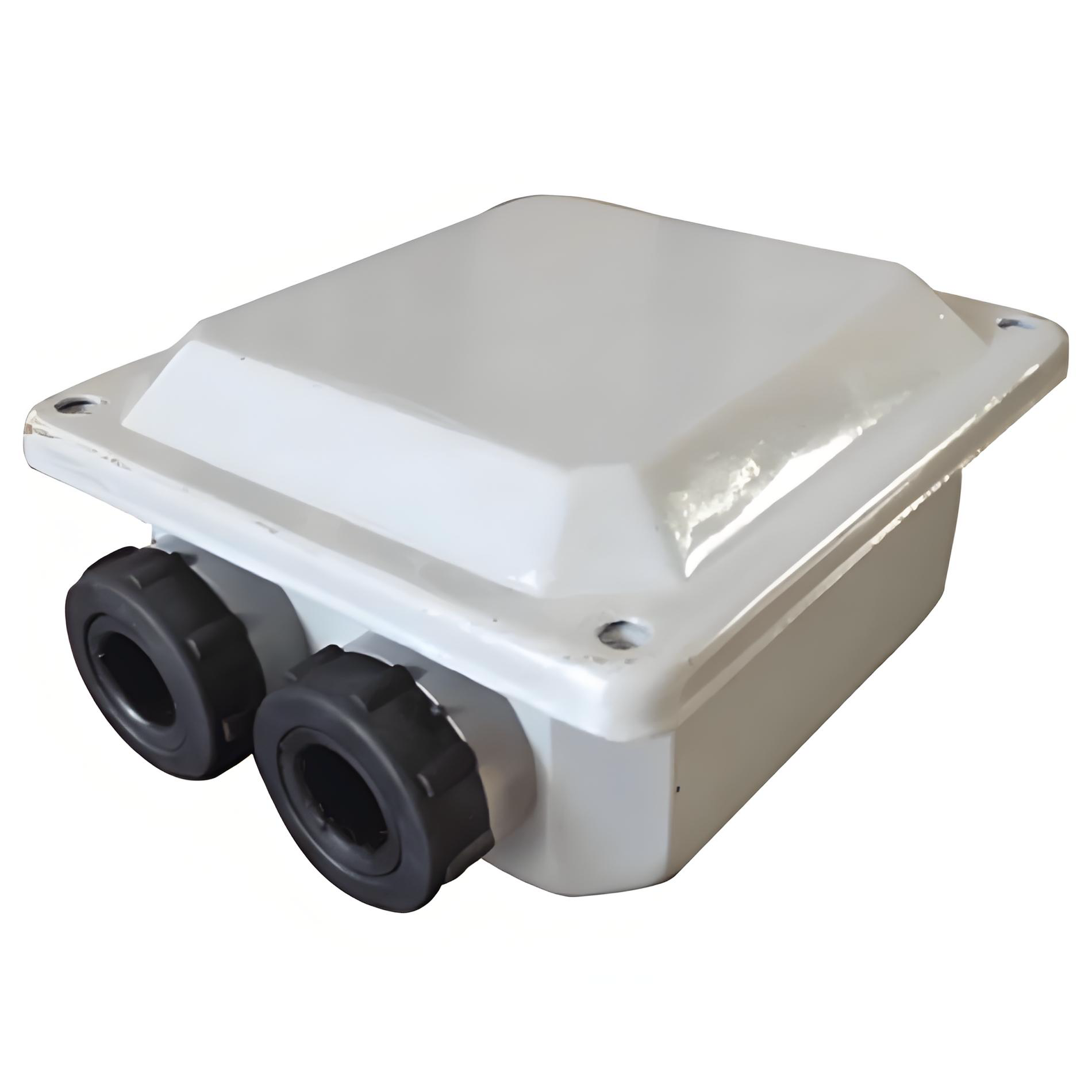

Installation and protection characteristics

- protection class: Basic IP21S with support for higher levels of customization

- Installation Standards: Conforms to GB/T997 and IEC international standards.

- Outline configuration: Standard positive box design, support reverse box customization

- Axis extension direction: Standard left exit shaft, support dual axle extension customization

Core Technology Advantage: Redefining DC Motor Performance Standards

Excellent speed control performance

Z4 series DC motor performance in speed controlsurpassing:

- Wide speed range: Supports a wide range of speed regulation requirements

- High precision of speed stabilization: Automatic speed stabilization function ensures operational stability

- Fast dynamic response: Fast response to load changes and speed commands

Efficient energy conversion

adoptionOptimized electromagnetic design solutions:

- Reduced iron and copper losses and improved efficiency ratings

- Improved commutation performance and extended brush life

- Enhanced heat dissipation to ensure continuous power output

Wide range of applications

Z4 series DC motors are suitable forMultiple industrial sectors:

- metallurgical industry: Rolling Mill Drive Systems

- machine tool manufacturing: Precision metal cutting equipment

- process industry: Paper, dyeing and printing machinery

- Heavy Industry: Cement and plastic extrusion equipment

Intelligent Control System Integration

Advanced ancillary accessories

be in favor ofMultiple function expansion modules:

- Tachymeter generator: Accurate Speed Feedback

- pulse generator: Position control applications

- Centrifugal Switch: Speed monitoring protection

- Brake systems: Quick stop function

Power Adaptation Features

- 160V model: Recommended for use with reactors (parameter nameplate labeling)

- 440V model: No need for an external reactor, direct use

- special specification: Support for customized voltage levels and excitation parameters

Xi'an Simo MotorQuality Assurance System

Authoritative certification and standards compliance

Z4 series DC motors strictly followDomestic and international technical standards:

- national standard: Conforms to the basic technical requirements of GB/T755

- international standard: At the level of the German VDE0530 standard

- quality system: ISO9001 quality management certification

- safety certification: CE, UL, CCC international certificates obtained

Commitment to professional and technical services

- Strict quality control: Full process quality control, unqualified never leave the factory

- Full Performance Testing: 72-hour continuous operation test to ensure reliability

- On-time delivery guarantee: Strictly on-schedule delivery, with priority given to special cases

- Fast after-sales response:: 24-hour technical response, 48-hour on-site service

- Improvement of the three-package policy: Three-pack service for quality issues, lifetime cost warranty

Professional Selection and Ordering Guide

Standard Selection Parameters

| Selection factors | Standard Options | Special Options |

|---|---|---|

| power range | 1.5-840kW | Customized power |

| voltage level | 160V/440V | Special Voltage |

| RPM Rating | 9 standard speeds | Customized RPM |

| Cooling method | 5 standard cooling | Special cooling |

| Installation form | IMB3 standard | Special Installation |

Technical requirements for ordering

Standard Ordering Information Requirements:

- Complete Motor Model Specifications

- Rated power and voltage class

- Speed range and excitation parameters

- Requirements for the form of the mounting structure

Special Configuration Notes:

- Environmental requirements: Moist heat belt type labeled "TH"

- Structural changes: Special requirements such as reverse box, reverse direction, etc.

- Annex requirements: Details of spare parts such as brushes, brush grips, etc.

- Non-standard customization: Special technology agreements signed

Recommended Application Scenarios

Key Industry Solutions

- Metallurgical rolling mill: High dynamic response, precise speed control

- Precision machine tools: Smooth low-speed operation with high torque output

- Production Line Transmission: Multi-motor synchronization, coordinated control

- special equipment: Special environmental adaptation for reliable operation

Recommendations for technology selection

Key considerations are recommended when choosing the right Z4 series DC motor:

- Load Characteristics: Constant torque/constant power demand

- Speed range: Requirements for speed regulation accuracy

- working cycle: Continuous or intermittent operation mode

- environmental conditions: Temperature, humidity, dust level

concluding remarks

Xi'an Taifu Simo Z4 series DC motor with itsLeading-edge technical design、Excellent performance和Reliable operating qualityThe newest and most important of all, it has become an important choice in the field of modern industrial transmissions.Simo motorsdepend onStrong technical strength和Perfect service systemWe provide each client withProfessional technical support和Timely after-sales protection。

If you need to know more about the technical characteristics of Z4 series DC motors or to obtain a personalized selection plan, please contact the professional technical team of Simo Motors, and we will be happy to provide you withFull range of technical services。

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206