Article Catalog[Hidden]

- Fully Enclosed Liquid Resistance Starter Cabinet: High-Performance Motor Starting Solution

Fully Enclosed Liquid Resistorstarter cabinetHigh-Performance Motor Starting Solutions

In the field of high-power motor starting,Totally enclosed liquid resistance starter cabinetWith its outstanding technical performance and ability to withstand harsh environments, it has become the ideal choice for industrial applications.

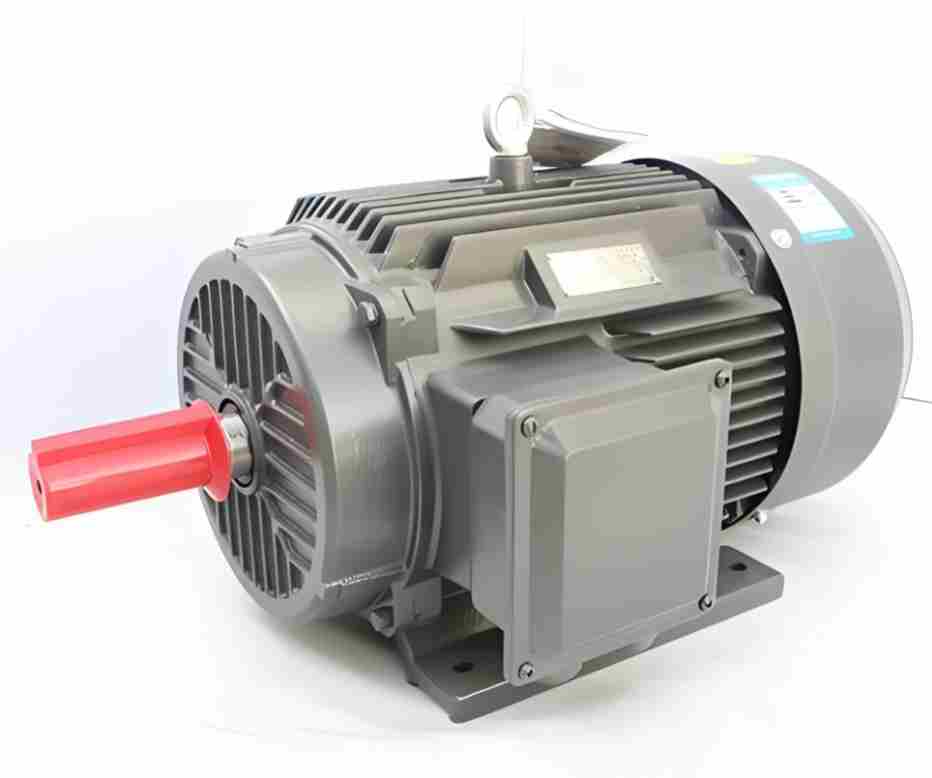

In the field of industrial motor control,Totally enclosed liquid resistance starter cabinetThis is an advanced starting device specifically designed for medium-to-large-sized wound-rotor asynchronous motors. It achieves motor starting by inserting a specially formulated liquid resistor into the motor's rotor circuit and altering the resistance value through the movement of plates.Smooth, shock-free start。

This starter cabinet employsFully enclosed structural designEquipped with a unique self-circulating cooling system and comprehensive sealing measures, it effectively resolves the issues of rapid electrolyte evaporation and inability to perform continuous starts associated with traditional liquid resistance starters.。

I. Working principle and technical characteristics

1. Smart Start Principle

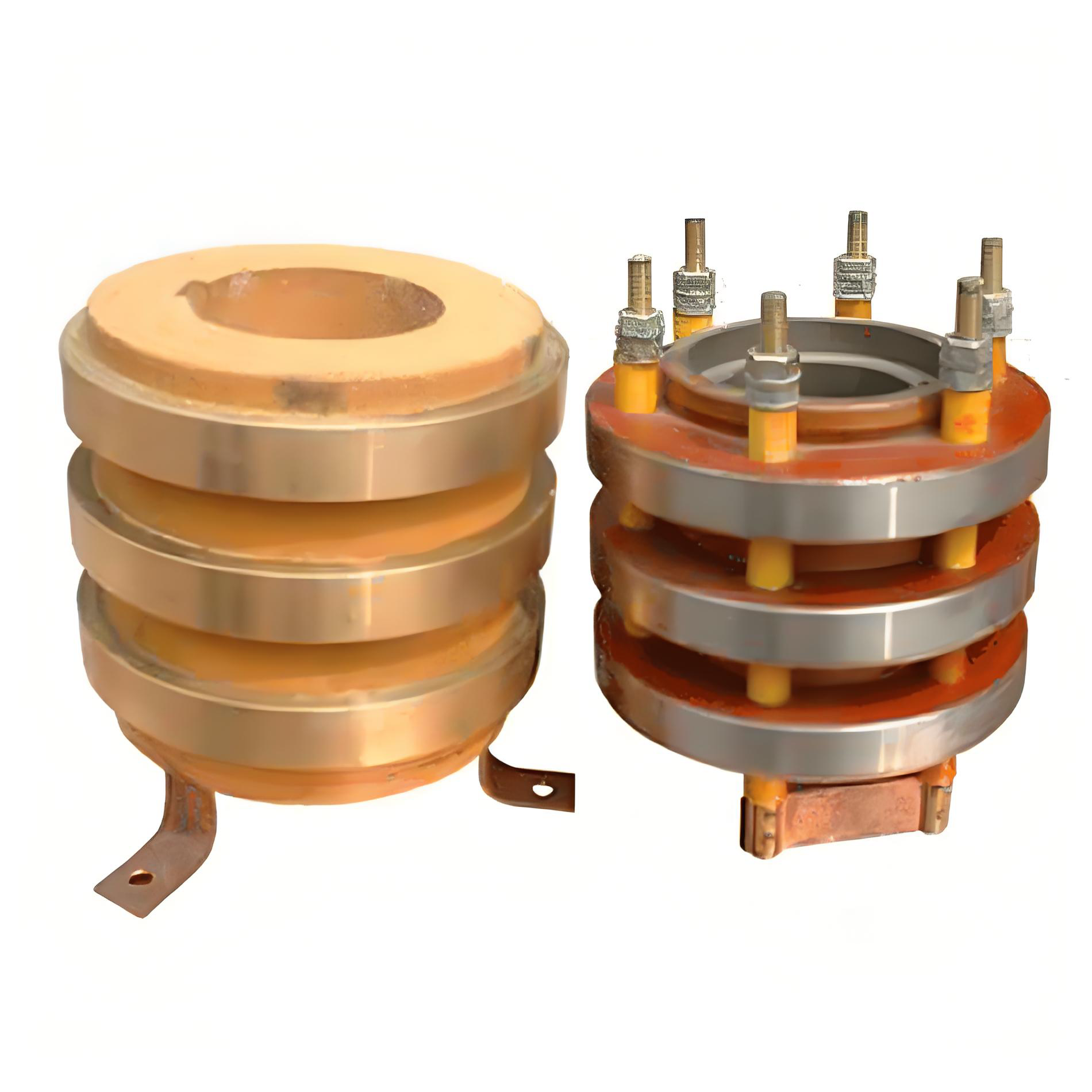

Fully enclosed liquid resistor starter cabinets operate based on the principle of inserting liquid resistors into the motor rotor circuit.When the starter receives the motor start signal, a low-power servo motor drives the pole plates to move, altering their relative positions and thereby changing the liquid resistance introduced into the rotor circuit.From large to small, undergoing infinite transformations。

When the resistance value decreases to its minimum, the short-circuit contactor closes, directly short-circuiting the star point of the motor rotor, thereby achieving the motor'sLow-current, high-torque smooth startThis intelligent starting method effectively reduces starting current and prevents impact on the power grid.

2. Advantages of Fully Enclosed Technology

- Improve the sealing systemThe cabinet and water tank feature a fully enclosed structure, with precision sealing measures implemented at all connection points. This includes dedicated sealing devices at the lifting insulator rod section, the fixed electrode plate lead-out array, and between the electrolyte tank and its cover.。

- Self-circulating coolingThe equipment is equipped with a circulation pump, forming a self-circulating cooling system comprised of external circulation components and internal circulation piping. This system rapidly dissipates heat generated within the electrolyte tank.。

- Wide environmental adaptability: Particularly suitable for long-term operation in arid climates with annual precipitation below 200 millimeters, addressing the issue of traditional liquid resistance starters prone to failure in harsh environments.。

II. Core Structure and Design Innovation

1. Modular structural design

Fully enclosed liquid resistor starter cabinet adoptsModular design conceptIt primarily consists of a fully enclosed enclosure, a contactor installation box, a control box, and a circulation system.This design not only enhances the reliability of the equipment but also makes maintenance and repairs safer and more convenient.

- Fully enclosed enclosureOnly the front cover plate is a movable component, while all other surfaces feature a fully enclosed structure, ensuring the protection rating reachesIP54 or higherEffectively prevents the ingress of dust, moisture, and corrosive gases.。

- Dedicated Electrolyte TankThe internal structure incorporates specially fabricated lifting frames, moving plates, and fixed plates made of insulating materials. Each plate is mutually insulated, ensuring balanced resistance across all three phases.。

- Plate Traction MechanismA worm gear hoist is employed as the transmission mechanism, connected to the lifting frame within the electrolyte tank via an insulated rod. This ensures smooth, reliable, and noise-free operation.。

2. Innovative Sealing Technology

The fully enclosed liquid resistance starter cabinet incorporates multiple innovations in sealing technology:

- Sealing for Telescopic Insulated PoleA specially designed sealing kit ensures that moisture from the electrolyte tank does not leak out during the lifting and lowering process of the insulated rod.。

- Sealing for the terminal plate lead-out stripA multi-layer sealing structure is installed at the lead-out busbar to prevent electrolyte leakage along the busbar.。

- Pressure Relief Valve SealThe pressure relief valve incorporates a precisely calculated counterweight that maintains a seal under normal conditions. When the gas pressure within the electrolyte tank rises to a predetermined level, the valve automatically opens to release the pressure.。

Third, the performance characteristics and advantages

The fully enclosed liquid resistance starter cabinet features multiple outstanding performance characteristics:

- Low starting currentThe starting current is less than the motor's rated current.1.3 timessignificantly reduce grid impact during the startup process。

- Continuous Starting CapabilityLarge heat capacity, capable of continuous starting5 to 10 timesMeet the demands of frequent starting operations。

- Low voltage starting capability: Capable of smooth startup even under unstable or low grid voltage conditions, the 6kV motor5.5 kilovolts380-volt motors in340 voltsCan start normally at any time.。

- Smooth and shock-freeThe starting process imposes no mechanical stress impact on the equipment, thereby extending the service life of both the machinery and the motor.。

- Easy to maintainFully automated operation with easy installation and maintenance, significantly reducing maintenance frequency.。

IV. Application areas and scenarios

Fully enclosed liquid resistance starter cabinets can be widely applied in the following fields:

- Heavy Industry SectorApplicable to industries such as cement, chemical, steel, metallurgy, and mining.75–10,000 kWHeavy-Duty Smooth Soft Start for Wound-Rotor Asynchronous Motors。

- Harsh environment:Particularly suitable for areas with insufficient annual precipitation200 millimetersOperating for extended periods in arid climates with low rainfall。

- Special operating conditions:Suitable for situations requiringMultiple consecutive startsIn situations where power supply is unstable or voltage is low, such as in industrial and mining enterprises.。

This device is commonly used for starting wound-rotor motors in transmission equipment such as ball mills, rolling mills, crushers, and fans, serving as an ideal replacement for frequency-sensitive variable resistance starter cabinets.。

V. Technical parameters and specifications

The main technical parameters of the fully enclosed liquid resistance starter cabinet are as follows:

VI. Selection and Installation Guide

1. Selection considerations

When selecting a fully enclosed liquid resistance starter cabinet, the following information must be provided:

- Motor model, rated power, rated rotor current, rotor voltage, and rated speed

- Load Characteristics Driven by Electric Motors (Operating Condition Description)

- Installation environment requirements, including any special usage requirements

- Cabinet surface color and other aesthetic requirements

2. Installation environmental requirements

To ensure the normal operation of fully enclosed liquid resistance starter cabinets, the installation environment must meet the following requirements:

- No significant shaking or impact vibrations in the surrounding area

- Non-corrosive gases

- Installation tilt angle shall not exceed5°

- Areas free from fire and explosion hazards

- Power Requirements: Three-phase, four-wire AC380V ±10% %

VII. Maintenance and Troubleshooting

Maintenance of fully enclosed liquid resistance starter cabinets is relatively straightforward:

- Regular inspectionPeriodically check whether the liquid level is within the normal range. When the liquid level falls below the marked line, add distilled water through the water inlet port after shutting down the machine and disconnecting the power supply.

- Seal InspectionRegularly inspect all sealing areas to ensure they are intact and free of leaks.

- Cardiovascular System ExaminationCheck whether the circulation pump and circulation piping are operating normally to ensure proper cooling.

- Protection Function VerificationPeriodically verify the reliability of protective functions such as liquid resistance over-temperature alarms, low liquid level detection, and startup timeout shutdown.

Fully enclosed liquid resistance starter cabinets are particularly suitable forSpecial environments such as drought and low rainfallin. itsFully enclosed structure和Unique self-circulating cooling systemEnsures stable operation of equipment under harsh working conditions.。

With the continuous advancement of industrial technology, fully enclosed liquid resistance starter cabinets willMore industries and fieldsDemonstrate its value and provide solutions for industrial enterprises.Reliable and cost-effective starting solutions for medium and large motors。

Shaanxi Public Security Bureau No. 41032502000206

Shaanxi Public Security Bureau No. 41032502000206